Hollow-out flexible printed circuit board

A flexible printing and circuit board technology, which is applied in the fields of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems that the hard board cannot be flattened, the weight of the product is increased, the AG wire is broken, etc., and the film-to-film pressure screen can be realized Excellent technology, good heat dissipation performance, and the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

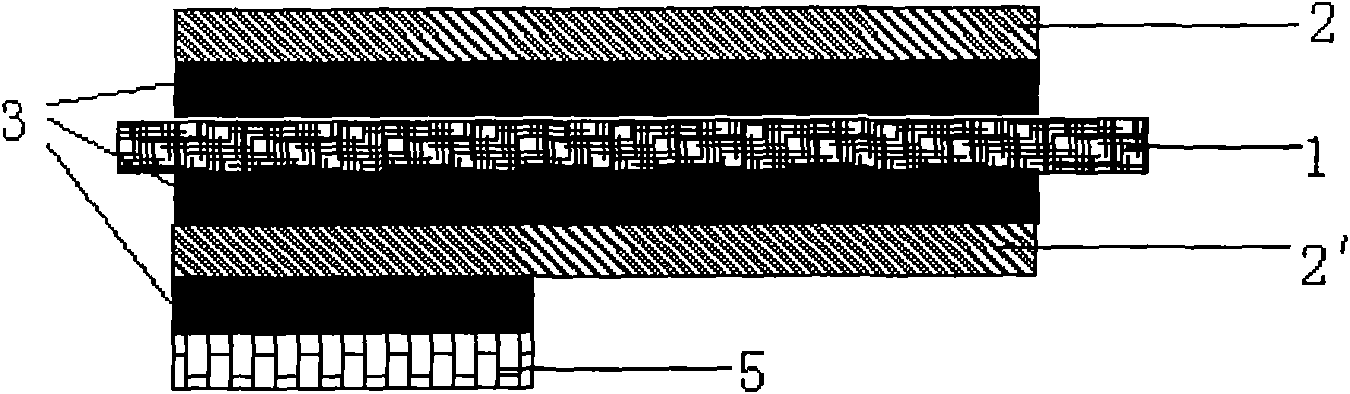

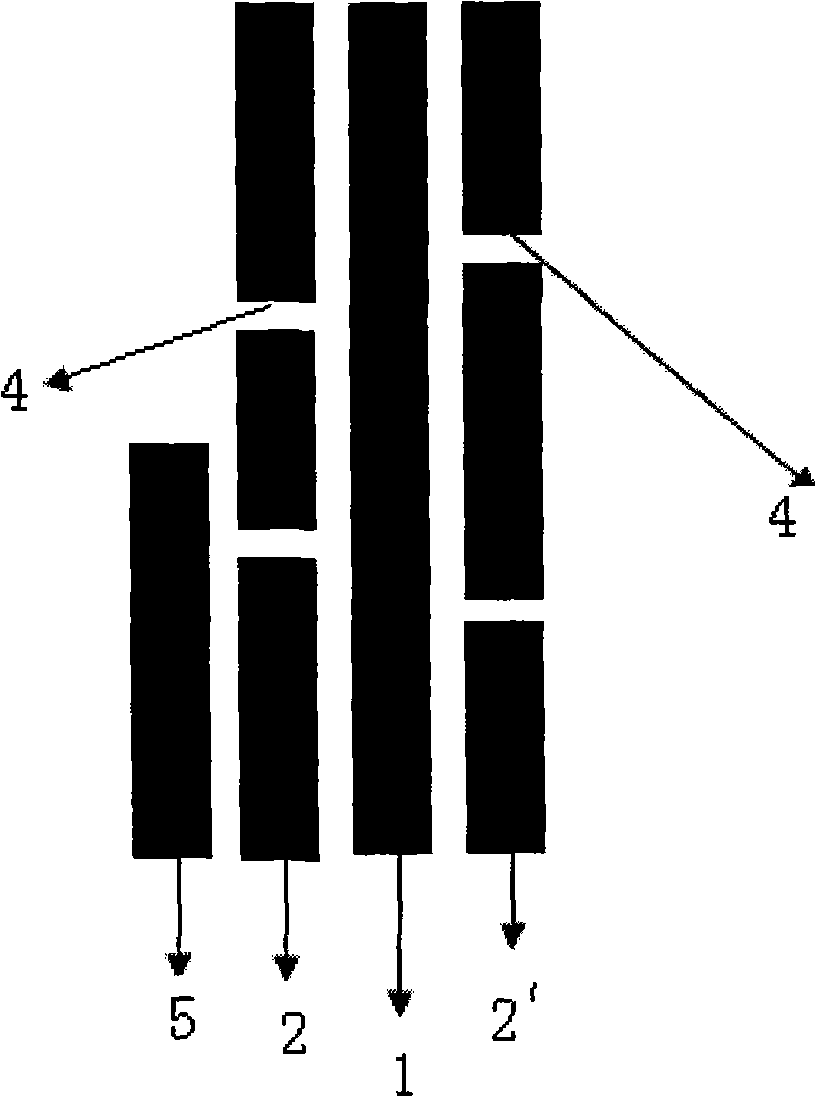

[0019] figure 1 It is a schematic diagram of the overall structure of an embodiment of the present invention; figure 2 It is a schematic side view of an embodiment of the present invention.

[0020] Such as figure 1 and figure 2 As shown, a hollow flexible printed circuit board includes a substrate 1 and a circuit formed thereon. The substrate 1 is pure copper foil. There is a pattern forming a line on the upper surface of the pattern, and the top surface of the pattern is provided with a PI cover film 2 on the upper surface that only exposes the opening 4 of the upper solder joint. The PI cover film 2 on the upper surface is provided with a PI cover film reinforcement 5. Both PI cover films 2, 2' and PI cover film reinforcement 5 contain Adhesive adhesive 3.

[0021] The above-mentioned upper surface and bottom surface PI covering films 2, 2' and PI covering film reinforcement 5 can also be polyester films.

[0022] First, the substrate 1 is cut, the bottom surface is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com