Arcuated alloy interlocking multi-energy cable

A metal cable, interlocking technology, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as the impossibility of 100% braiding density, insufficient resistance to external force and mechanical protection, limited cable bending performance, etc., to achieve excellent shielding effect. , The structure is simple and practical, and the effect of reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

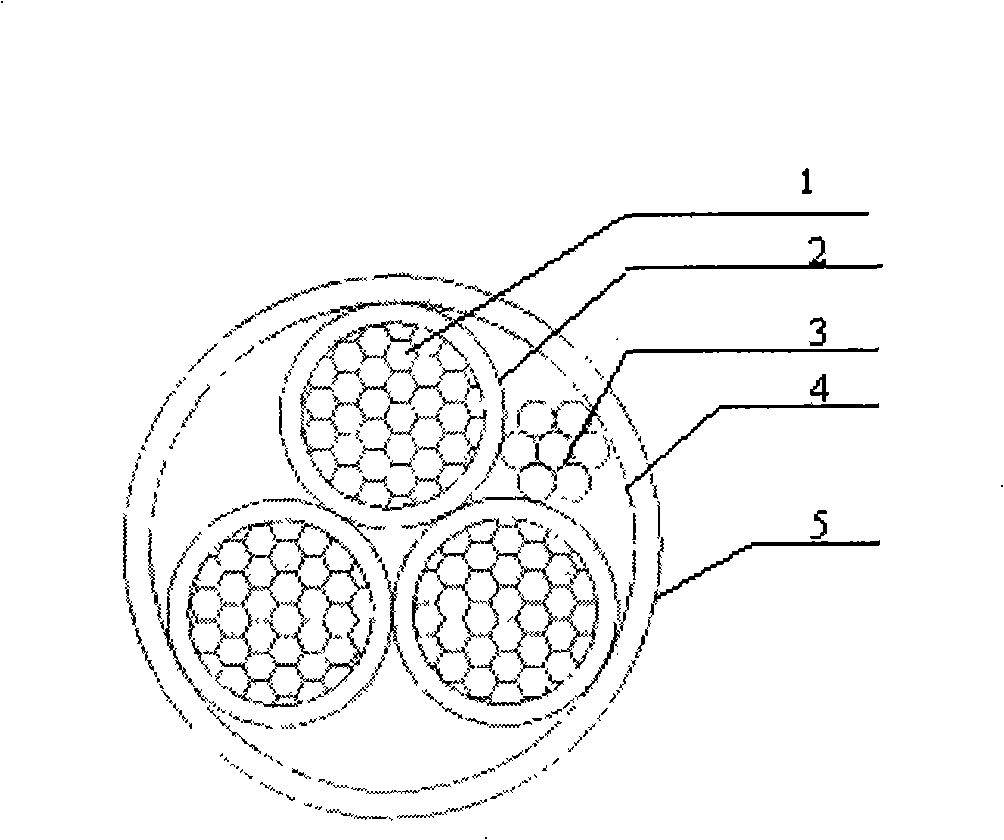

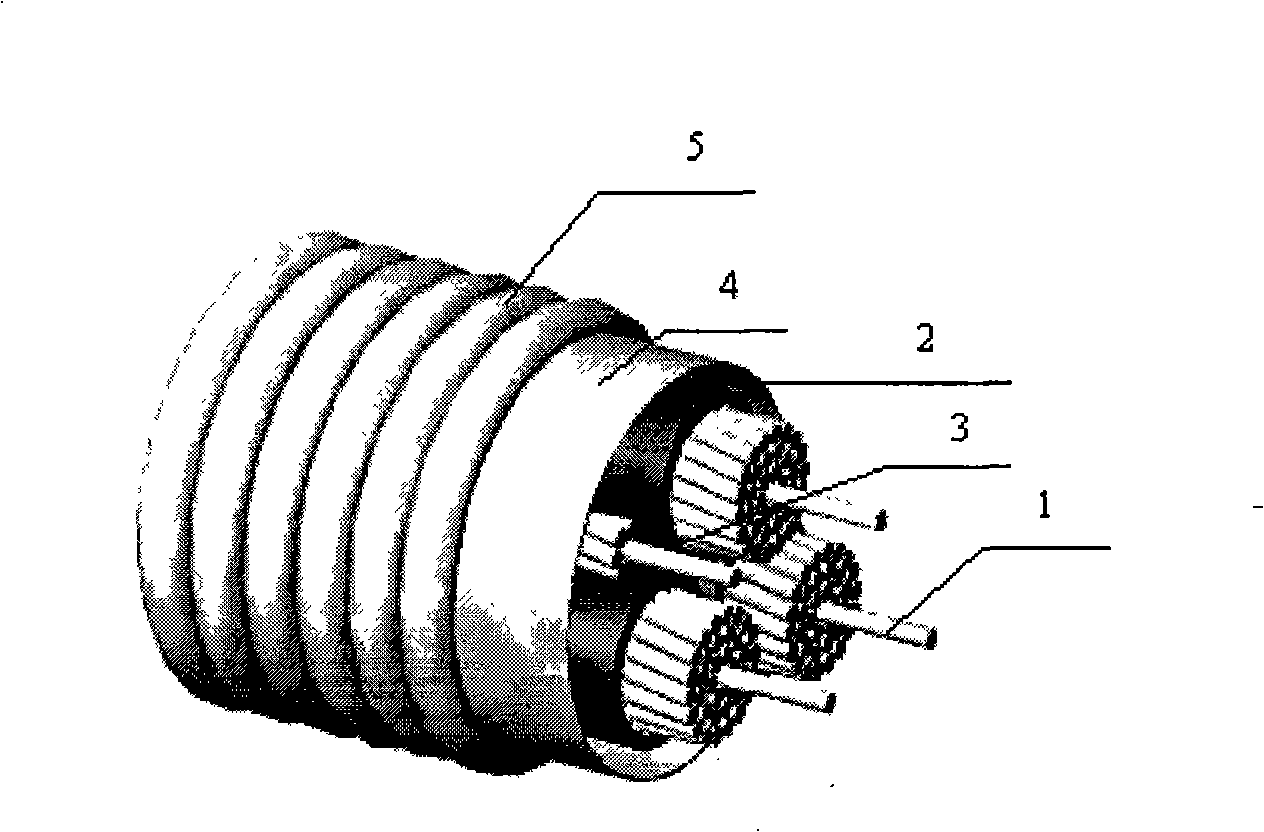

[0016] see figure 1 with figure 2 As shown, the metal cable includes a cable core and a metal cladding layer wrapped around the periphery of the cable core, wherein the metal cladding layer is an arc-shaped interlocking buckle armor structure, and the arc-shaped interlocking buckle The armor structure includes several ring-shaped metal fastening units 5 , the longitudinal section of which is S-shaped, and each ring-shaped metal fastening unit 5 is sequentially interlocked and fastened.

[0017] Wherein, one end of each ring-shaped metal fastening unit 5 of the metal cable is interlocked and fastened to the outer wall of the previous ring-shaped metal fastening unit 5 adjacent to it, and the other end of the ring-shaped metal fastening unit 5 is interlocked. Fit to the inner wall of the next annular metal fastening unit 5 adjacent to it.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com