Electric Wire Sheathing Member And Wire Harness

A technology for wires and fittings, applied in the field of wire outer fittings and wiring harnesses, can solve problems such as difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

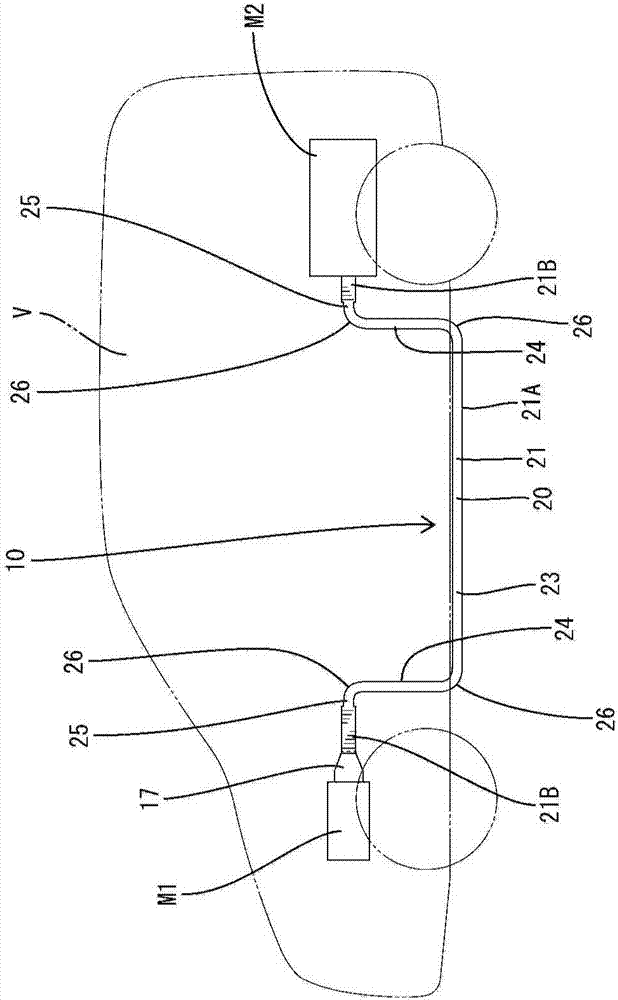

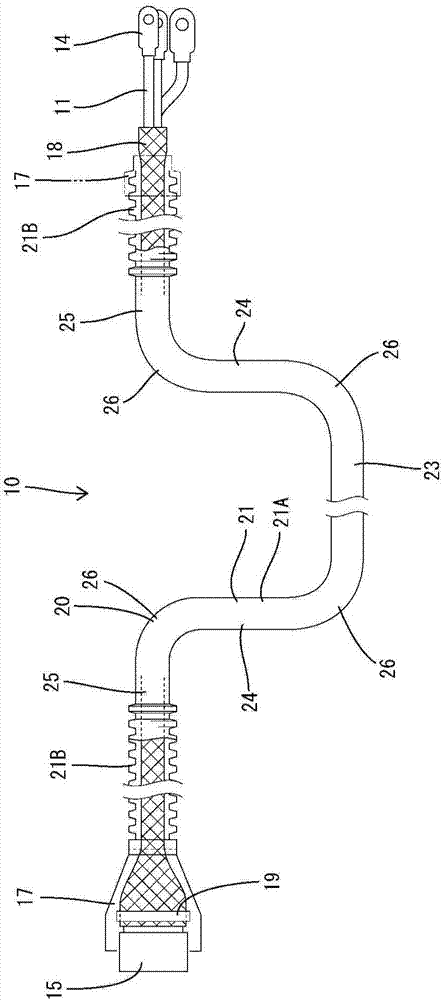

[0014] Preferred embodiments of the present invention are shown below.

[0015] In the electric wire sheathing material of the present invention, the corrugated portion may extend integrally in the axial direction from the end portion of the straight pipe portion. According to such a configuration, the corrugated portion can be bent freely, and the connection work of the wire harness can be easily performed.

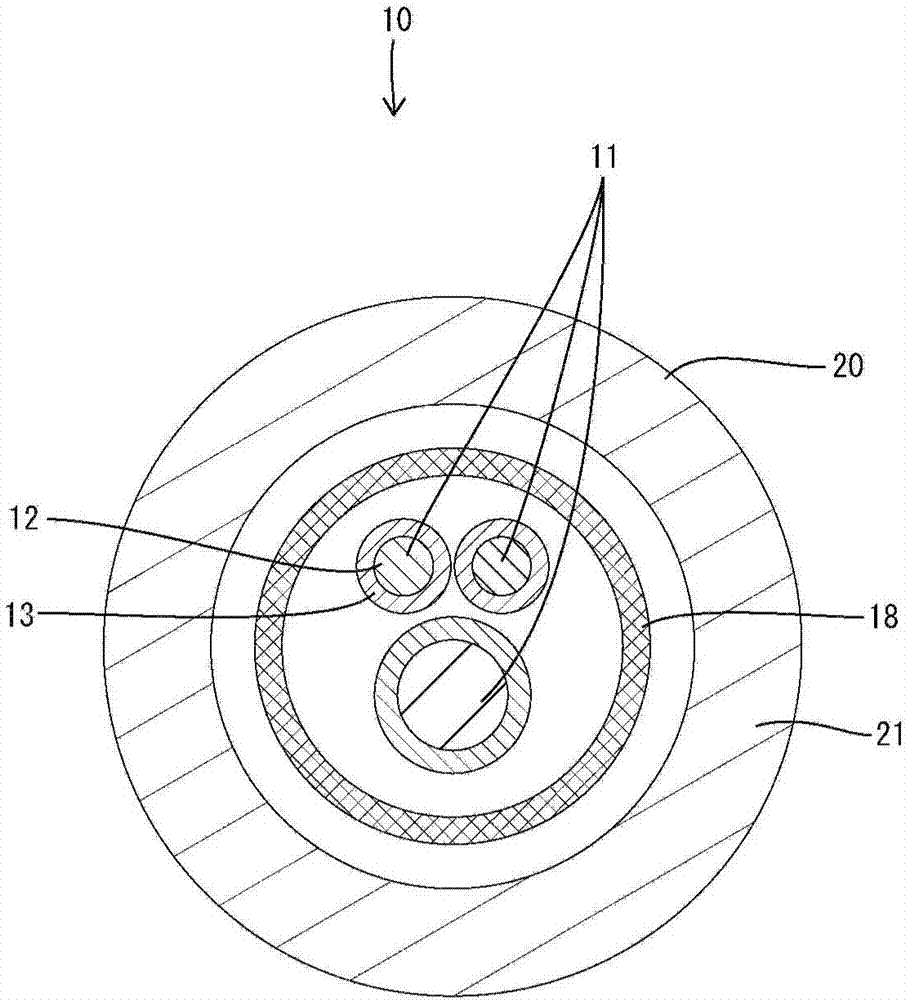

[0016] In addition, the wire sheathing material of the present invention may include a braided wire formed in a cylindrical shape from a plurality of metal wires, and the braided wire is arranged inside the above-mentioned resin tube to surround the above-mentioned wire, or is arranged to surround the above-mentioned resin tube. On the outside of the above-mentioned resin tube.

[0017] According to this configuration, the entire length of the electric wire is shielded by the braided wire. Here, when shielding the portion passing through the metal pipe with the metal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com