Hollow-out double-sided flexible printed circuit board with ACP conductive adhesive being printed thereon

A flexible printing and conductive adhesive technology, applied in printed circuit, printed circuit manufacturing, printed circuit components, etc., can solve problems such as space occupation, safety hazards, AG wire breakage, etc., achieve conductive particle distribution rules, eliminate use safety , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

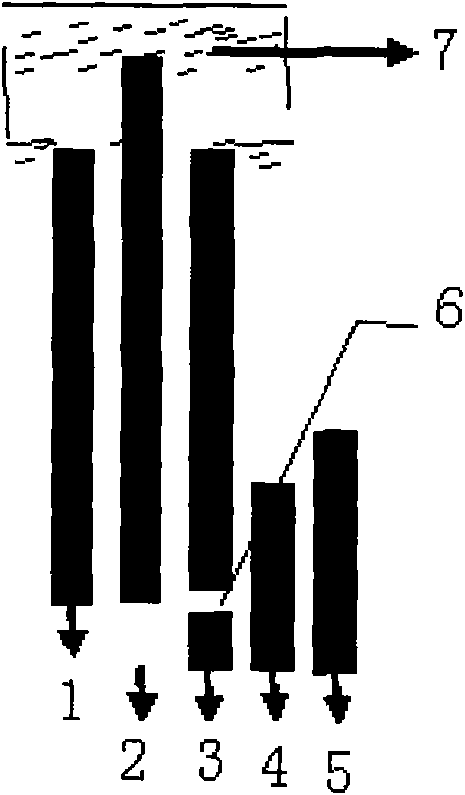

[0020] figure 1 It is a schematic diagram of the side mechanism of an embodiment of the present invention.

[0021] Such as figure 1 As shown, a hollow double-sided flexible printed circuit board printed with ACP conductive glue includes a substrate 2, a surface covering film 1, a bottom covering film 3, a copper strip 4 and a copper strip covering film 5, wherein the surface covering film 1 and The bottom cover film 3 is respectively pressed on the surface of the substrate 2 and the ground, the surface cover film 1 is provided with solder joint openings (not shown in the figure), and the bottom cover film 3 is provided with a guide hole 6 to realize conduction on both sides. The strip 4 is pressed on the bottom cover film 3 at the position where wiring is required, and pure glue is pasted between it and the bottom cover film 3. The bottom cover film 3 and the copper strip 4 have a circuit pattern on the surface, and a layer of wire is pressed on the surface of the line. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com