An inspection robot mechanism suitable for narrow inspection workspace

A technology for inspection robots and workspaces, which is applied to manipulators, manufacturing tools, overhead lines/cable equipment, etc., can solve the problems of poor safety protection, complex structure, high energy consumption, etc., and achieve reduced size and weight, safety protection Good, the effect of reducing the exercise space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

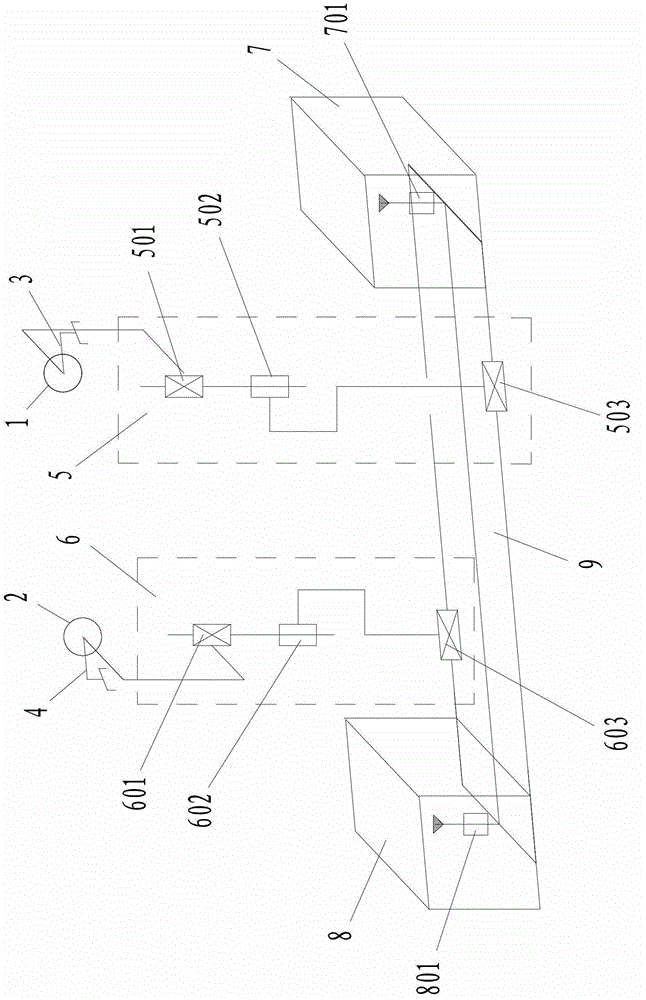

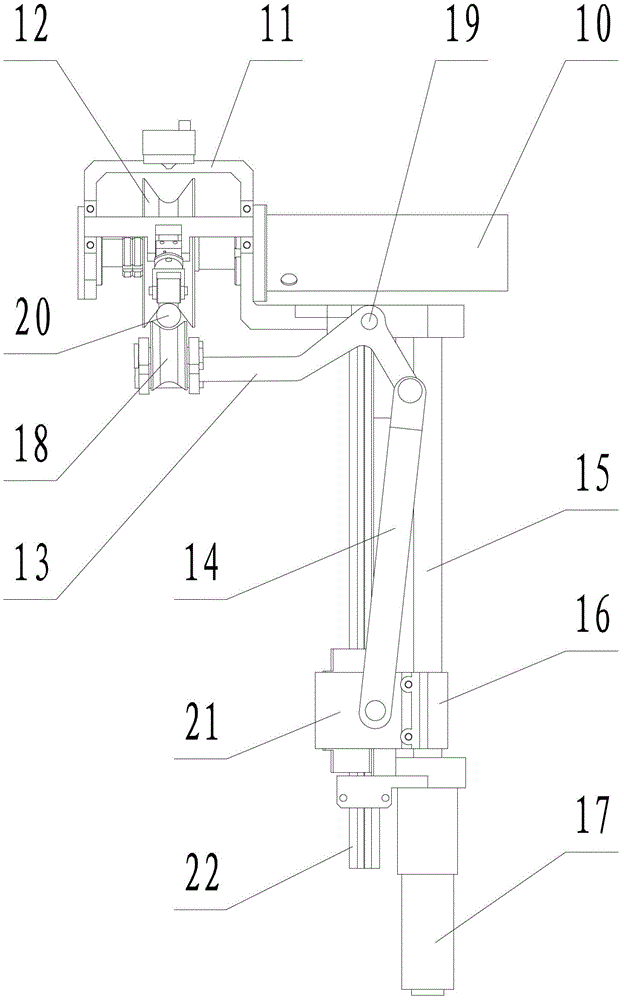

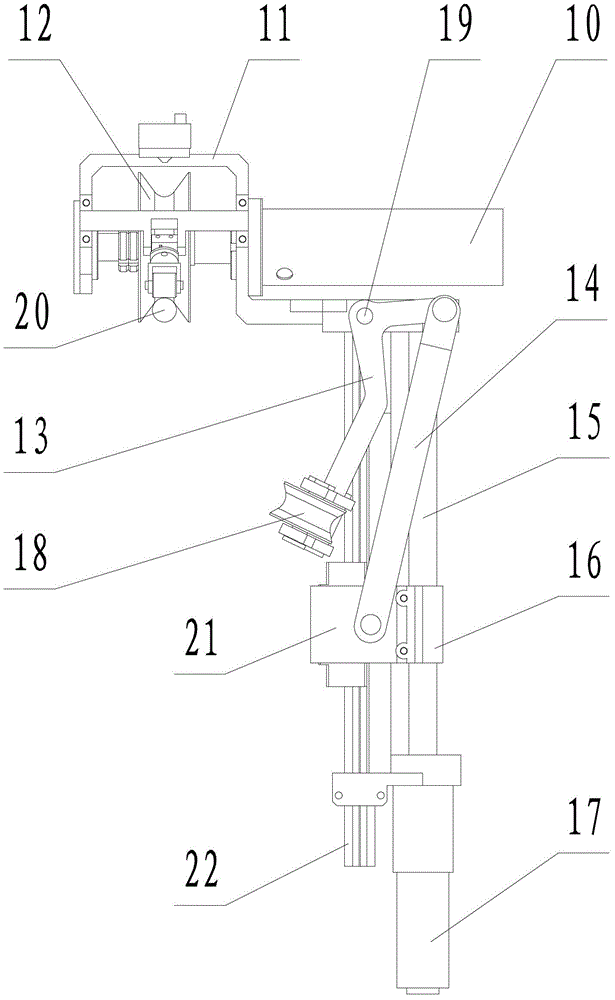

[0031] Such as figure 1 Shown, the present invention comprises front box body 7, rear box body 8, first guide rail 9 and structure identical front arm 5 and rear arm 6, and wherein front traveling mechanism 1 and front clamping mechanism 3 are respectively installed on the front arm 5, The rear traveling mechanism 2 and the rear clamping mechanism 4 are respectively installed on the rear arm 6, and the front box body 7 has the same structure as the rear box body 8; the front traveling mechanism 1 and the front clamping mechanism 3 are respectively located above and below the overhead ground wire 20, The rear traveling mechanism 2 and the rear clamping mechanism 4 are respectively located above and below the overhead ground wire 20 . There are at least two first guide rails 9 (three in this embodiment), each first guide rail is parallel to each other, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com