Novel foam packing and sleeving device

A foam and sleeve technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaging items, to achieve the effect of reducing the cost of packaging materials and eliminating hidden dangers of instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

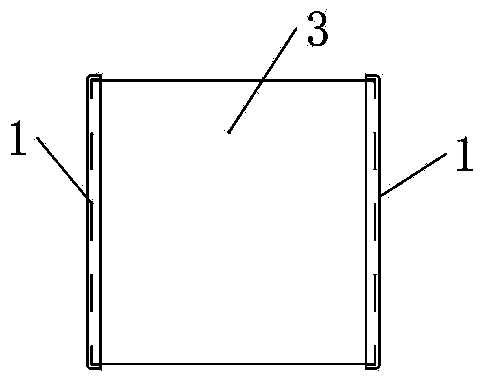

[0034] like Figures 9 to 18 As shown, the novel foam packing device 4 of the present invention comprises a packing cylinder 41, a supporting plate 411, a long retaining bar 421, a short retaining bar 422, a horizontal support platform 43, a stacking frame 44, a stacking device 45, a bearing Support lifting frame 46, foam conveying device 47, height limit plate 48 and rolling needle telescopic cylinder group 49. In specific applications, two sets of foam enclosing devices 4 are required to be symmetrically arranged to complete the foam enclosing work of the ceramic tile 3 respectively, wherein Figures 9 to 14 The foam in the figure is an example of double-sided small foam 1, and the specific structure is as follows:

[0035] The horizontal support platform 43 is arranged on the top of the short retaining bar 422, and is used to support the double-sided small foam 1 falling from the stacking frame 44. Specifically, the end of the horizontal support platform 43 is flat with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com