Heterojunction battery assembly with approximately zero battery piece spacing, and preparation method thereof

A technology of heterojunction cells and cells, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of product load reliability risk, process cracking and other problems, so as to improve the safety performance of components, reduce the cost of packaging materials, and reduce the cost of packaging materials. Effects of Power Loss and Risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

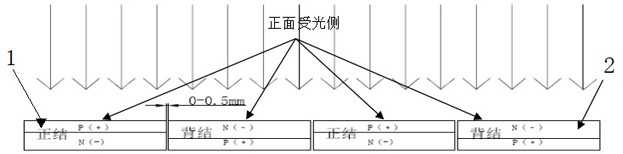

[0039] see Figure 3~4 and Figure 7 , the present invention relates to a heterojunction battery assembly with approximately zero cell spacing, which includes a battery string array with six rows and two columns consisting of six battery strings on the left side and six battery strings on the right side, and each battery string is An array of ten rows and twelve columns of cells, each row of cells includes alternately arranged positive junction cells 1 and back junction cells 2, two adjacent back junction cells 2 and positive junction cells 1 are provided with front side welding strips 3. Two adjacent positive-junction cells 1 and back-junction cells 2 are provided with back-side ribbons 4 , and the ends of the back-side ribbons 4 correspond to the centers of the upper front-side ribbons 3 .

[0040] The two ends of the front soldering ribbon 3 reserve a length of 5-20 mm as a single string of positive and negative output.

[0041] The six battery strings on the left side an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com