Silicon carbide anti-skinning refractory spray coating

A silicon carbide and anti-skinning technology, which is applied in the field of silicon carbide anti-skinning refractory spray coatings, can solve the problems of unguaranteed construction quality, high cost, and difficulty in installing molds, so as to improve chemical corrosion resistance and anti-skinning ability, improving high temperature strength, and improving the effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

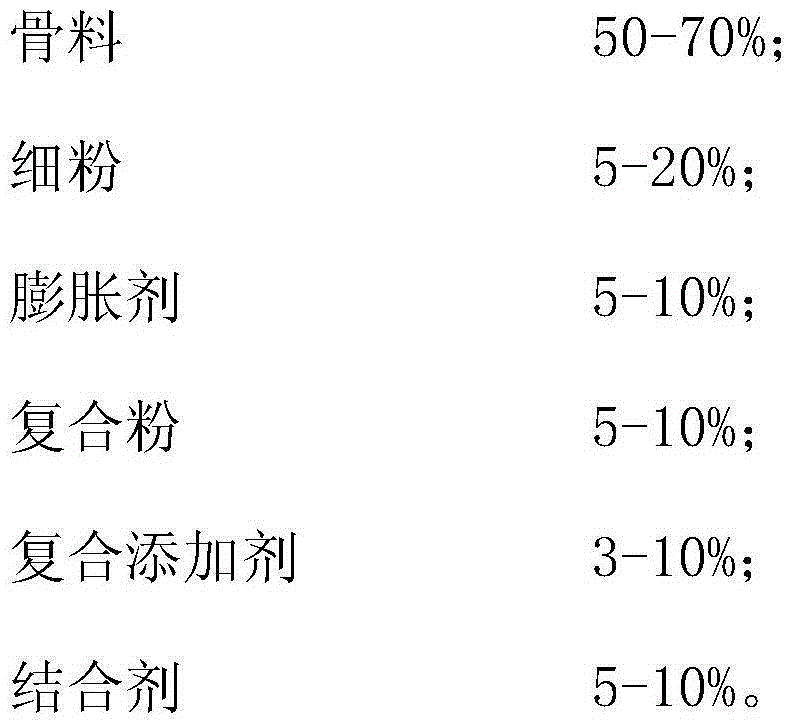

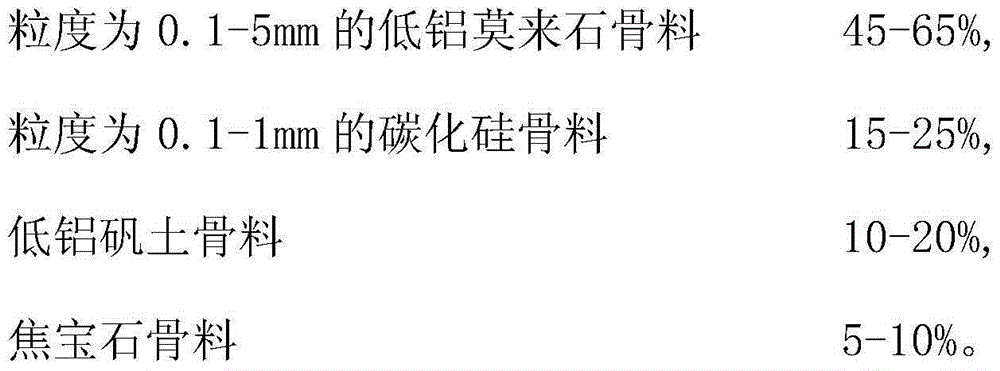

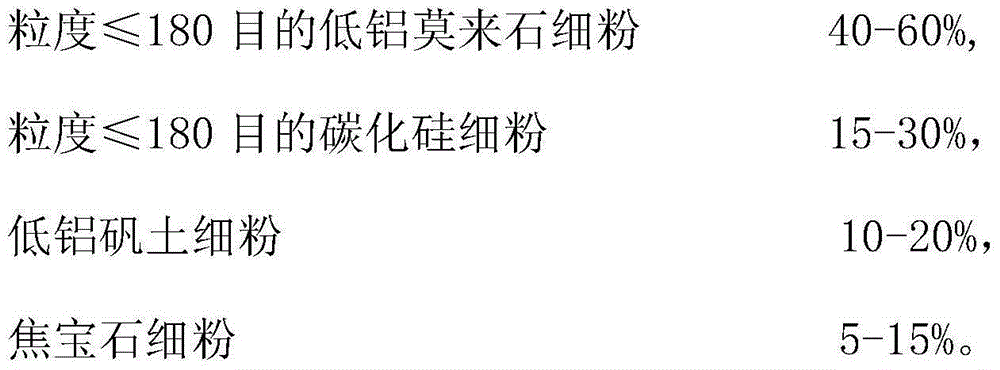

Embodiment 1

[0033] The silicon carbide anti-skinning refractory spray coating includes the following components and the mass percentage of each component is: aggregate 50%, fine powder 20%, expansion agent 10%, composite powder 10%, composite additive 5%, binder 5%, as preferred, the spray coating is only composed of aggregate, fine powder, expansion agent, composite powder, composite additive and binder, wherein one part of aggregate includes low-aluminum mullite bone with a particle size of 0.1-5mm 50% material, 30% silicon carbide aggregate with a particle size of 0.1-1mm, low-alumina bauxite aggregate and 20%, and a portion of fine powder includes 45% of low-alumina mullite fine powder with a particle size of ≤180 mesh and a particle size of ≤180 Objective silicon carbide fine powder 35% and low bauxite fine powder 20%, the expansion agent is a combination of kyanite and sillimanite, or, the expansion agent is a combination of andalusite and sillimanite, or, the The expansion agent is...

Embodiment 2

[0036] Silicon carbide anti-skinning refractory spray coating includes the following components and the mass percentage of each component is: aggregate 70%, fine powder 5%, expansion agent 5%, composite powder 5%, composite additive 10%, binder 5%, as preferred, the spray coating is only composed of aggregate, fine powder, expansion agent, composite powder, composite additive and binder, wherein one part of aggregate includes low-aluminum mullite bone with a particle size of 0.1-5mm 70% silicon carbide aggregate with a particle size of 0.1-1mm, 15% low-alumina bauxite aggregate and 15%, and a portion of fine powder includes 60% of low-alumina mullite fine powder with a particle size of ≤180 mesh and a particle size of ≤180 Purpose silicon carbide fine powder 30% and low bauxite fine powder 10%, described expansion agent is the combination of kyanite and sillimanite, perhaps, described expansion agent is the combination of andalusite and sillimanite, or, all The expansion agent...

Embodiment 3

[0038] The silicon carbide anti-skinning refractory spray coating includes the following components and the mass percentage of each component is: aggregate 60%, fine powder 12%, expansion agent 8%, composite powder 7%, composite additive 8%, binder 5%, as preferred, the spray paint is only composed of aggregate, fine powder, expansion agent, composite powder, composite additive and binder, wherein, one part of aggregate includes low-aluminum mullite bone with a particle size of 0.1-5mm 60% material, 20% silicon carbide aggregate with a particle size of 0.1-1mm, low-bauxite aggregate and 20%, and a portion of fine powder includes 55% of low-alumina mullite fine powder with a particle size of ≤180 mesh and a particle size of ≤180 Purpose silicon carbide fine powder 30% and low bauxite fine powder 15%, described expansion agent is the combination of kyanite and sillimanite, perhaps, described expansion agent is the combination of andalusite and sillimanite, or, all The expansion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com