Paper machine and printing method

A paper machine and printing device technology, applied in the field of paper making, can solve problems such as inability to produce new paper and anti-counterfeit paper, and user troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

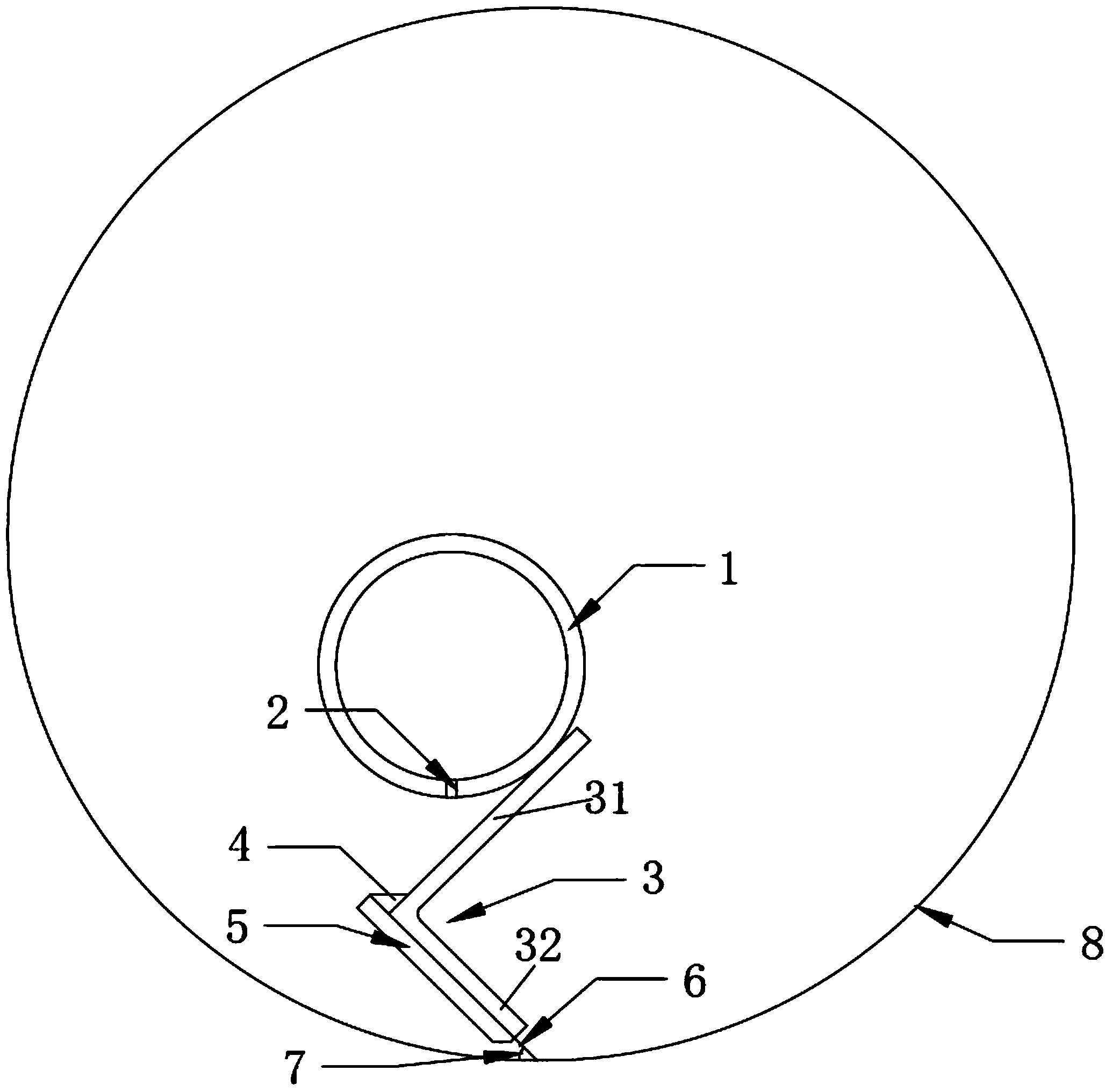

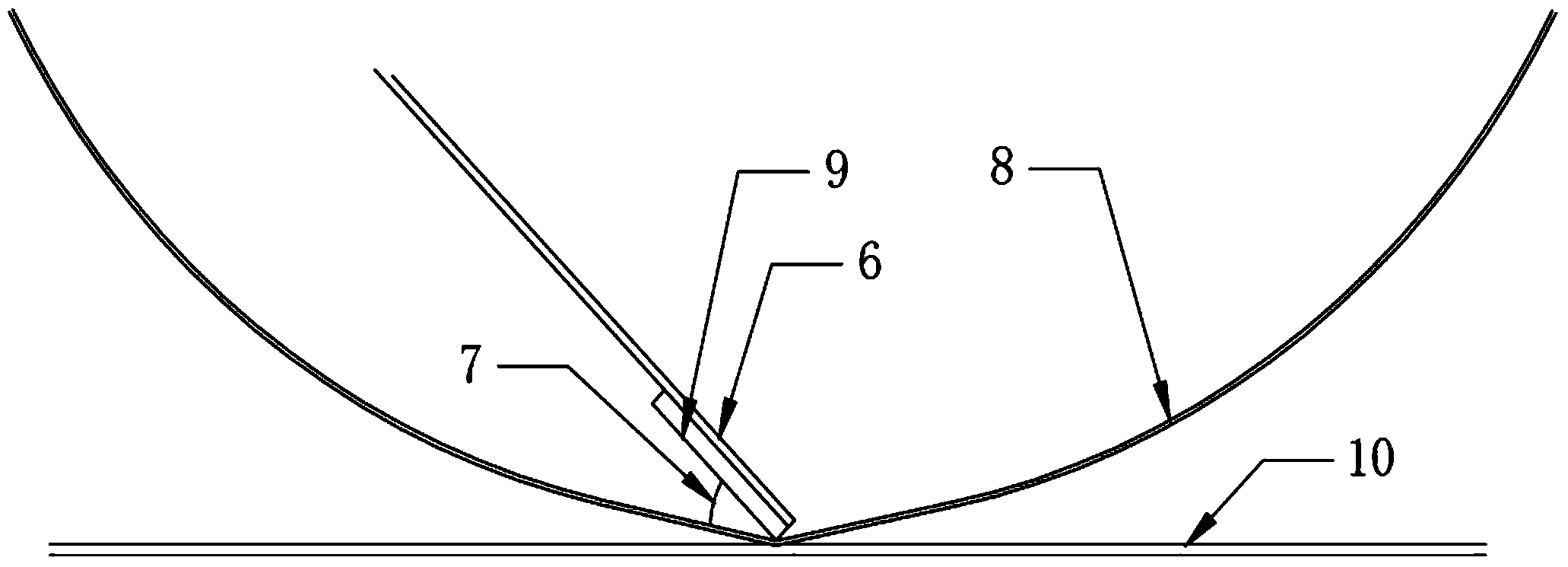

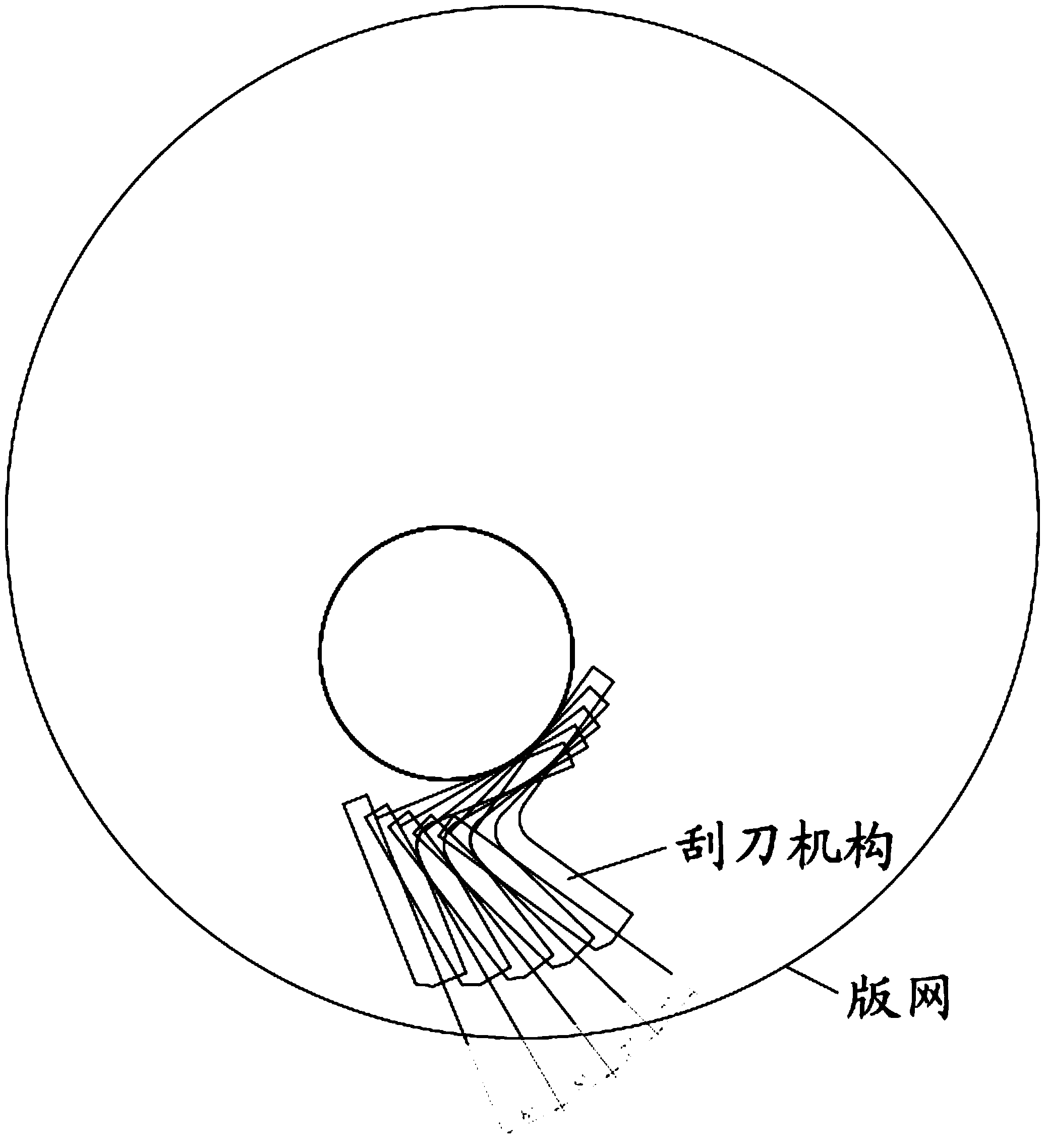

[0032] Such as Figure 15 to Figure 17 As shown, the present invention discloses a paper machine, including a paper machine body, a printing device, the paper machine body includes a negative pressure adsorption device, and a pulp forming wire for carrying pulp, and the negative pressure adsorption device is located at the pulp forming One side of the net, the printing device is located on the other side of the pulp forming screen, the negative pressure adsorption device and the printing device are symmetrically placed on both sides of the pulp forming screen, and the printing device is used to print the pulp, The negative pressure adsorption device is used to absorb the pulp on the pulp forming net, and suck the printed ink into the pulp layer.

[0033] The printing device includes a silk screen printing device, or a gravure printing device, or an embossing printing device, and the negative pressure adsorption device is a vacuum box.

[0034] When the gravure printing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com