An installation structure of a prestressed connector

A technology for installing structures and connectors, which is applied to structural elements, building components, building reinforcements, etc., can solve the problems that protective pipes cannot be blocked, and achieve the effects of avoiding accidental fall-off failure, ensuring sealing, and ensuring effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

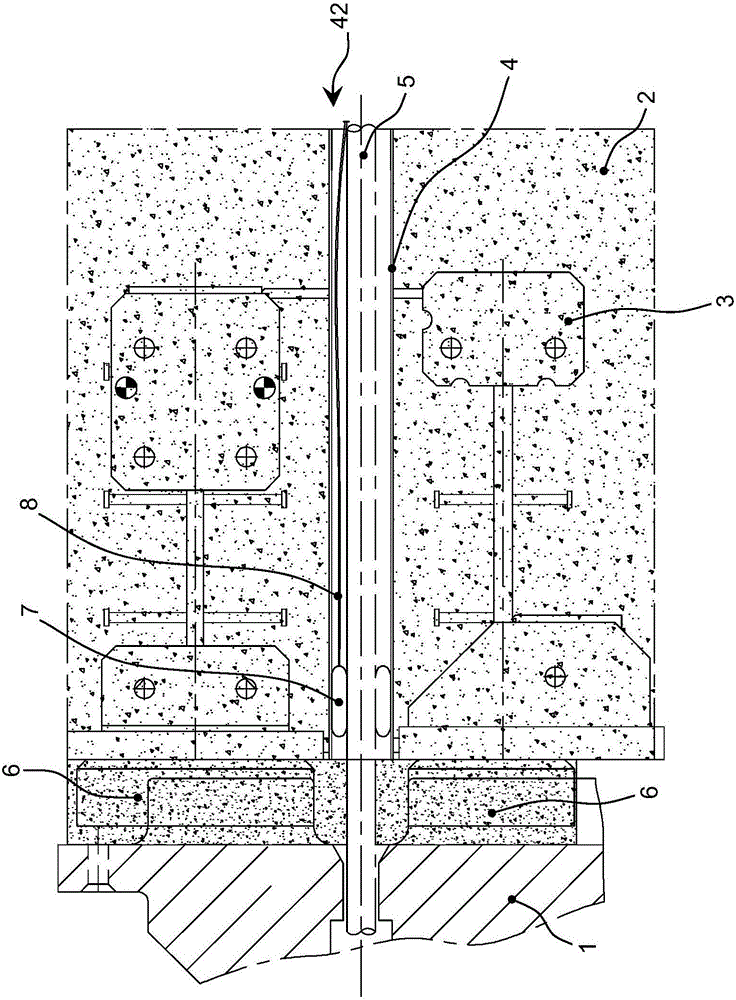

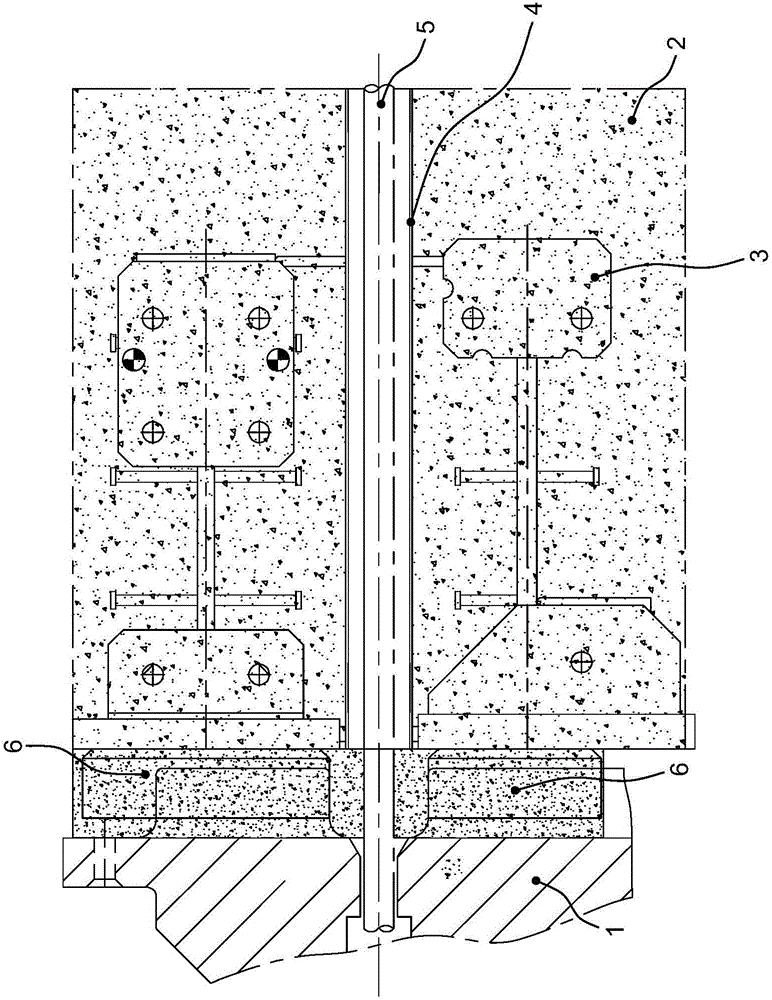

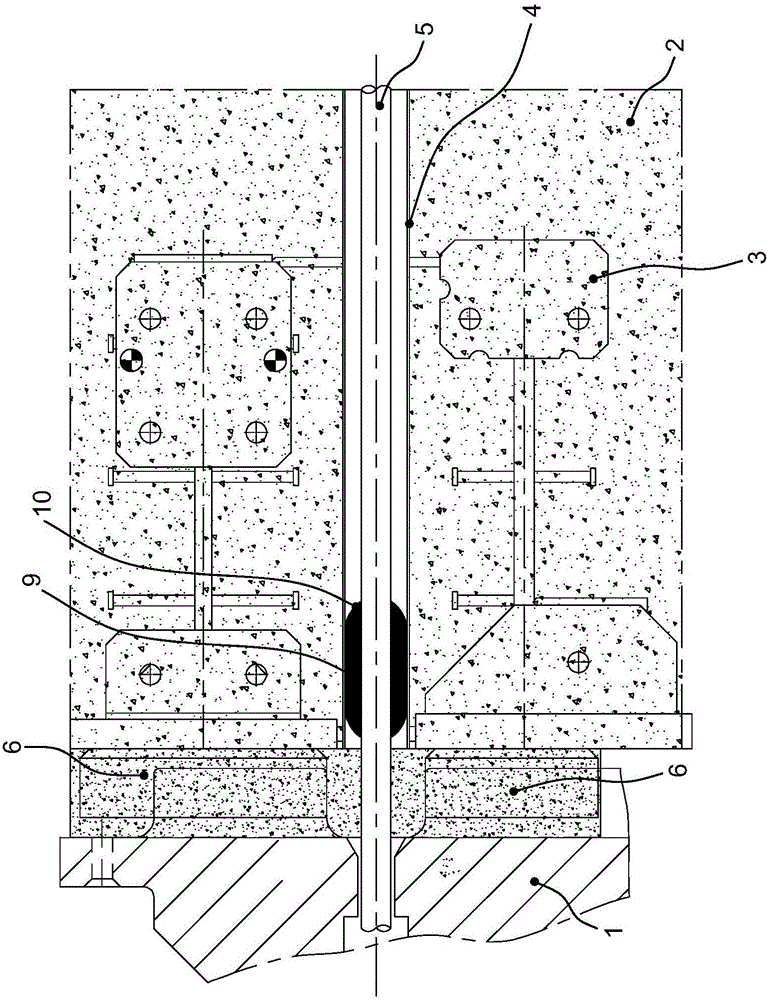

[0032] Such as figure 2 As shown, when the exposed equipment 1 is installed on the concrete foundation facade 2, the embedded parts 3 in the foundation facade 2 and the exposed equipment 1 will be fixed by prestressed connectors 5 . The concrete foundation facade 2 can be a ship lock wall or a similar facade, and the sealing method of the present invention certainly does not exclude the application on a horizontal foundation surface. The embedded part 3 is a basic part welded by steel plate and steel parts, and the embedded part 3 and the foundation facade 2 are integrally casted. Protective pipeline 4 can be a PVC pipe, is positioned at embedded part 3 middle parts, and protective pipeline 4-open end 41 (see image 3 ) is slightly lower than the outer surface of the foundation facade 2. The connecting piece 5 can be a steel piece in the form of a stud, and its inner end 42 is fixed to the foundation facade 2 by a fastener (this end is not fully drawn in the figure). The c...

no. 2 example

[0045] Such as Figure 8 As shown, when the exposed equipment 1 is installed on the concrete foundation facade 2, the embedded parts 3 in the foundation facade 2 and the exposed equipment 1 will be fixed by prestressed connectors 5 . The concrete foundation façade 2 can be a ship lock wall or the like, although application on horizontal foundation surfaces is of course not excluded. The embedded part 3 is a basic part welded by steel plate and steel parts, and the embedded part 3 and the foundation facade 2 are integrally casted. Protective pipeline 4 can be a PVC pipe, is positioned at embedded part 3 middle parts, and protective pipeline 4-open end 41 (referring to Figure 10 ) may be slightly lower than the outer surface of the foundation facade 2. The connecting piece 5 can be a steel piece in the form of a stud, and its inner end is fixed to the foundation facade 2 by a fastener (this end is not fully drawn in the figure). The connecting piece 5 and the concrete founda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com