Leakage protection plug

A leakage protection plug and pin technology, applied in circuits, electrical components, contact parts, etc., can solve the problems of lack of fire protection, defective fire performance of plugs, and fire may burn out from the shells on both sides of the contacts. Safety, the effect of reducing poor contact, avoiding fire and electric shock hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

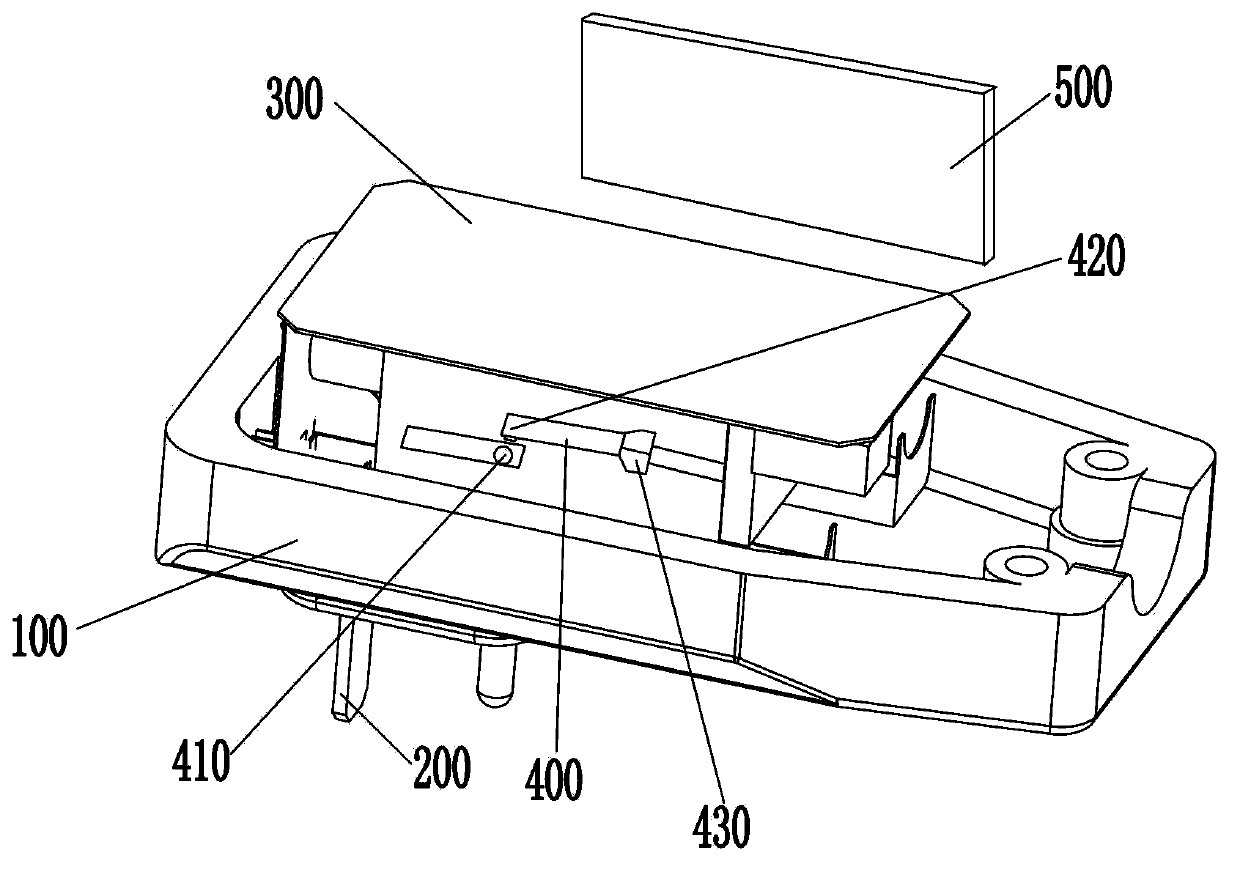

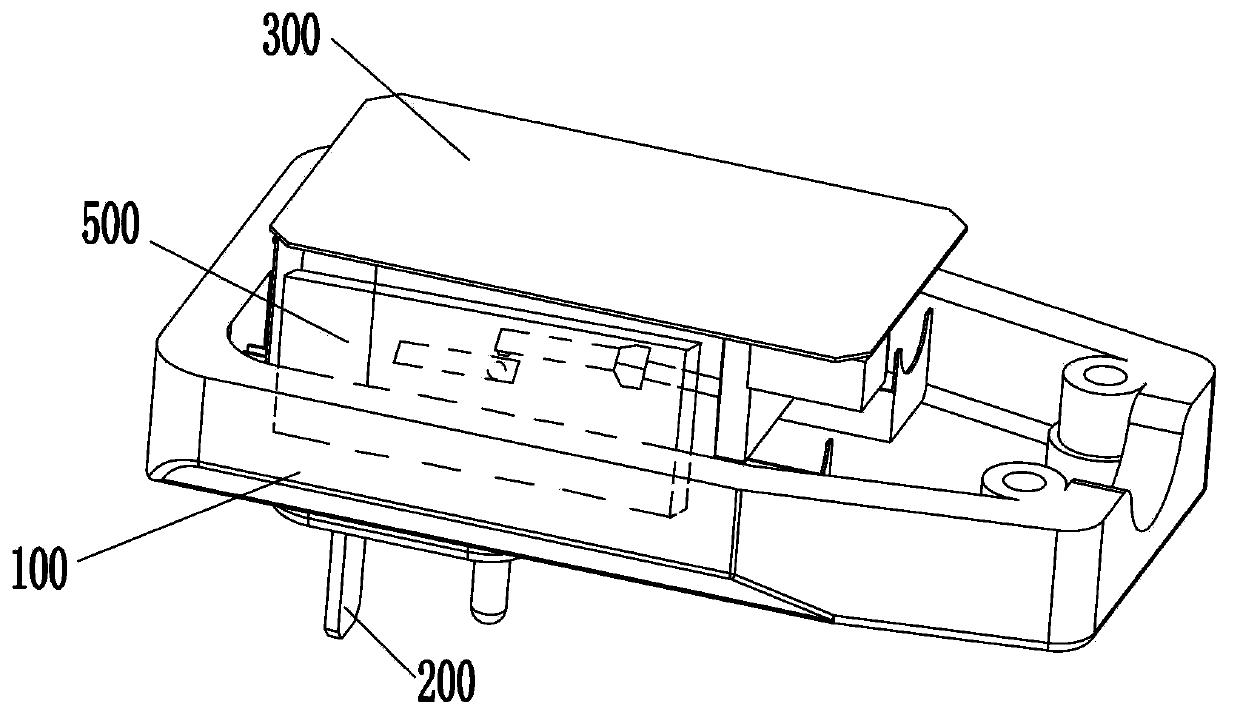

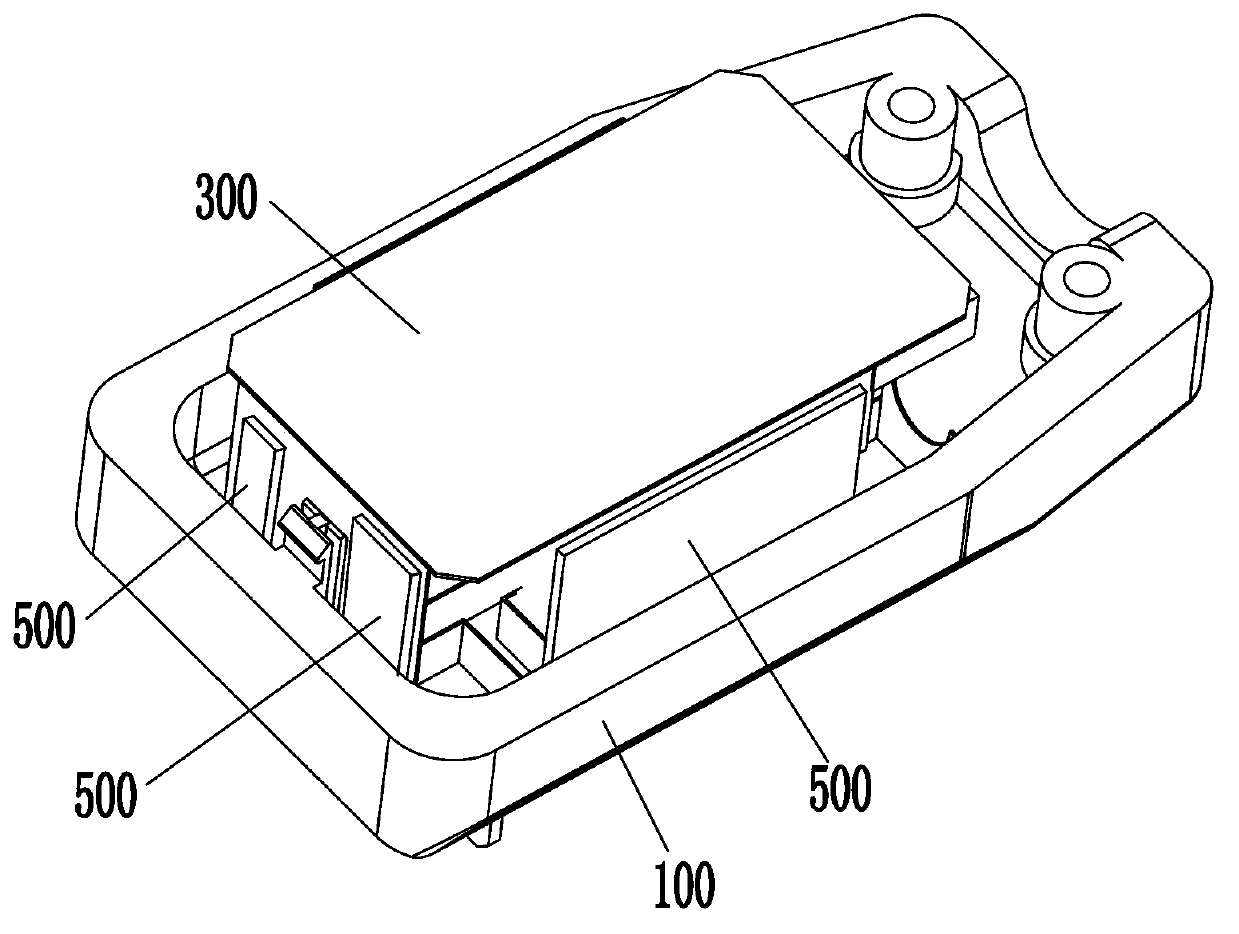

[0028] An embodiment of the leakage protection plug of the present invention, as Figure 1 to Figure 3 shown.

[0029] The leakage protection plug of the present invention includes a housing 100, a pin 200, a circuit board 300, a contact 410, a crimping terminal 400 and a fire damper 500;

[0030] The circuit board 300 , the contacts 410 , the crimping terminals 400 and the fire damper 500 are arranged inside the housing 100 ;

[0031] The contacts 410 and the crimping terminals 400 are arranged correspondingly;

[0032] The pin 200 is connected to the contact 410 or the crimp terminal 400 through the lower part of the housing 100 ;

[0033] The circuit board 300 is arranged on the upper part inside the housing 100;

[0034] The contact 410 is arranged on the lower part of the circuit board 300;

[0035] The fire damper 500 is disposed between the contact 410 and the housing 100 .

[0036] Before the fire damper 500 of the present invention is installed, the distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com