Method for operating an electric arc furnace and melting plant having an electric arc furnace operated according to said method

A technology for melting equipment and electric arc furnaces, which can be used in lighting and heating equipment, furnaces, electric heating devices, etc., and can solve problems such as grid disturbance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

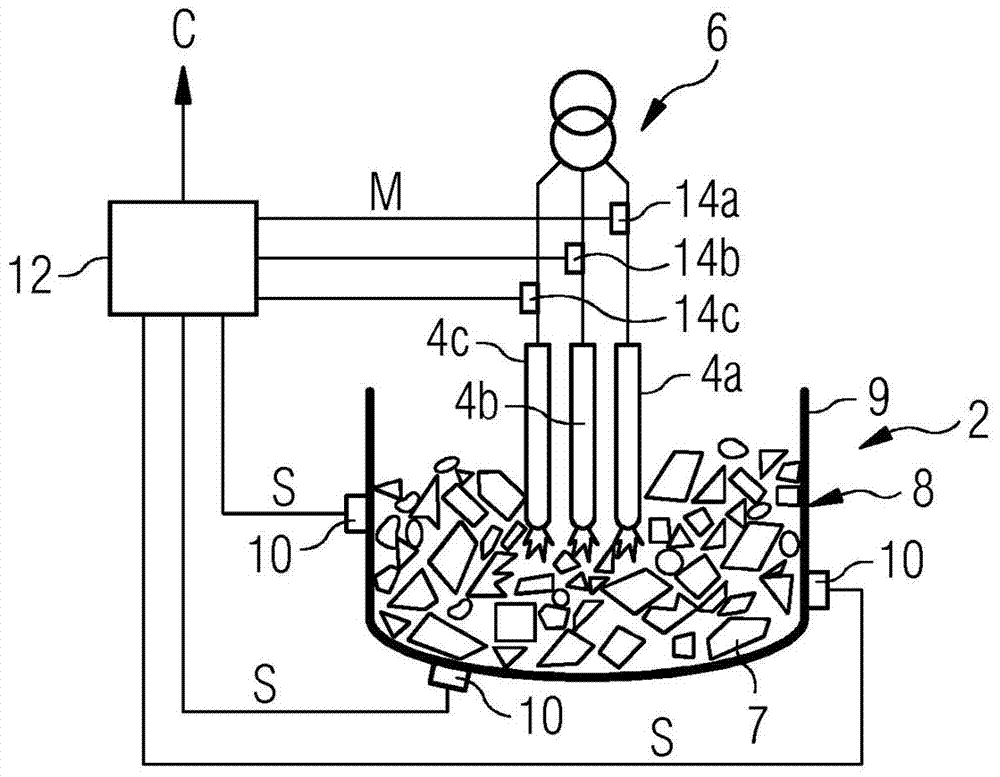

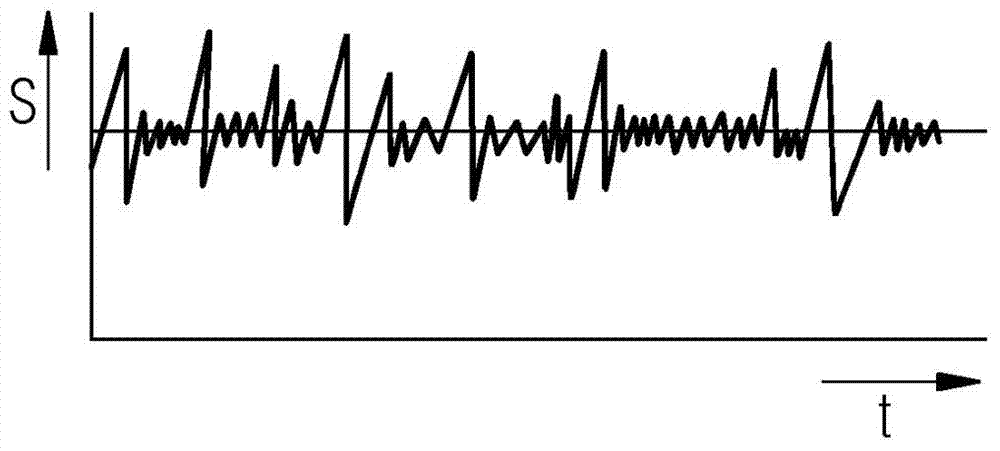

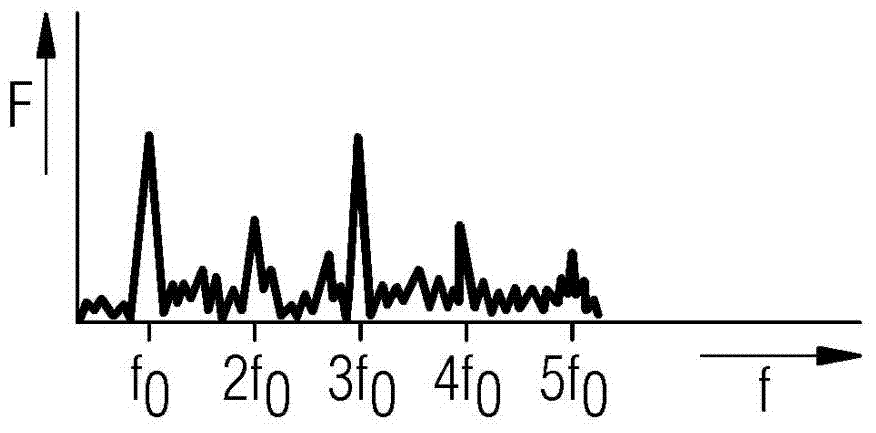

[0030] according to figure 1 , the melting plant according to the invention comprises an electric arc furnace 2 having, for example, three electrodes 4 a - c which are electrically connected to a furnace transformer of a power supply 6 . The electrodes 4a-c are sunk into a furnace vessel 8 containing the scrap 7 to be melted, on the wall 9 of which a plurality of structure-borne sound receivers 10 are arranged. The structure-borne sound signal S detected by the structure-borne sound receiver 10 is transmitted to a control and evaluation device 12 for further processing.

[0031] In addition to the structure-borne sound signal S, the current flowing in the electrode 4 and / or the voltage applied thereto is measured by means of the measured value receivers 14 a - c and a corresponding measurement signal M is transmitted to the control and evaluation device 12 . In this control and evaluation device, a control signal C is generated, by means of which at least one process variable...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap