power tool

A power tool and power source technology, which is applied in the field of power tools, can solve the problems that the ring gear and the meshing gear cannot be smoothly meshed, and cannot be smoothly shifted and switched, so as to achieve the effect of smooth change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

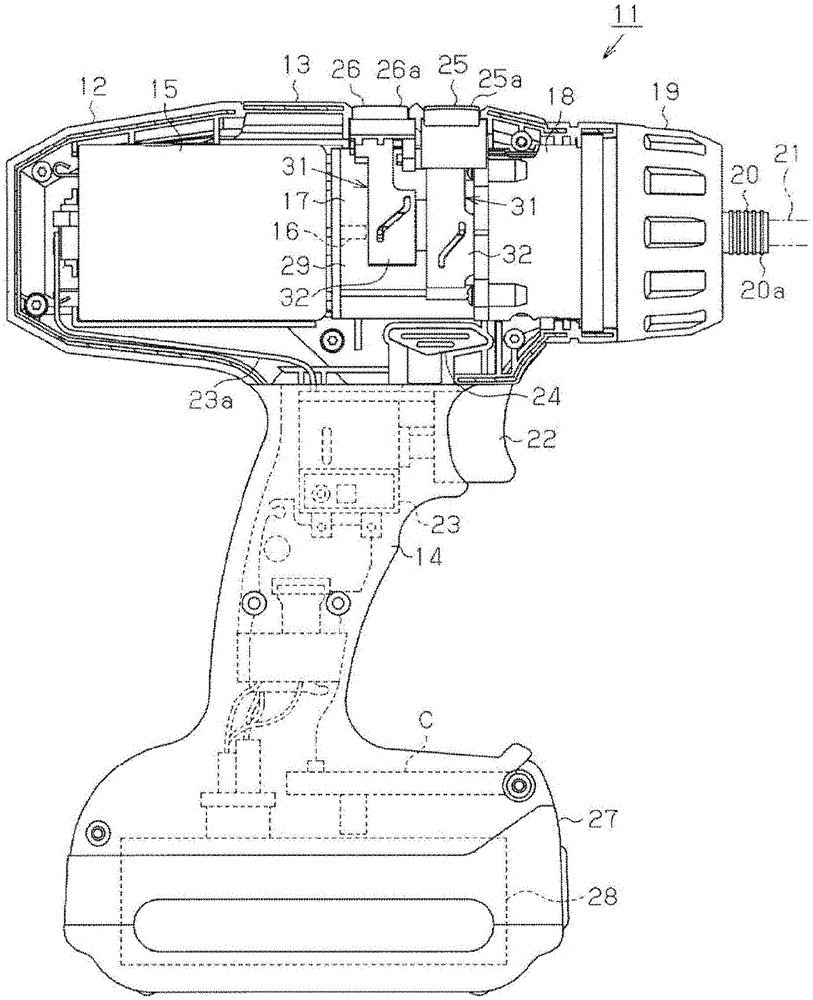

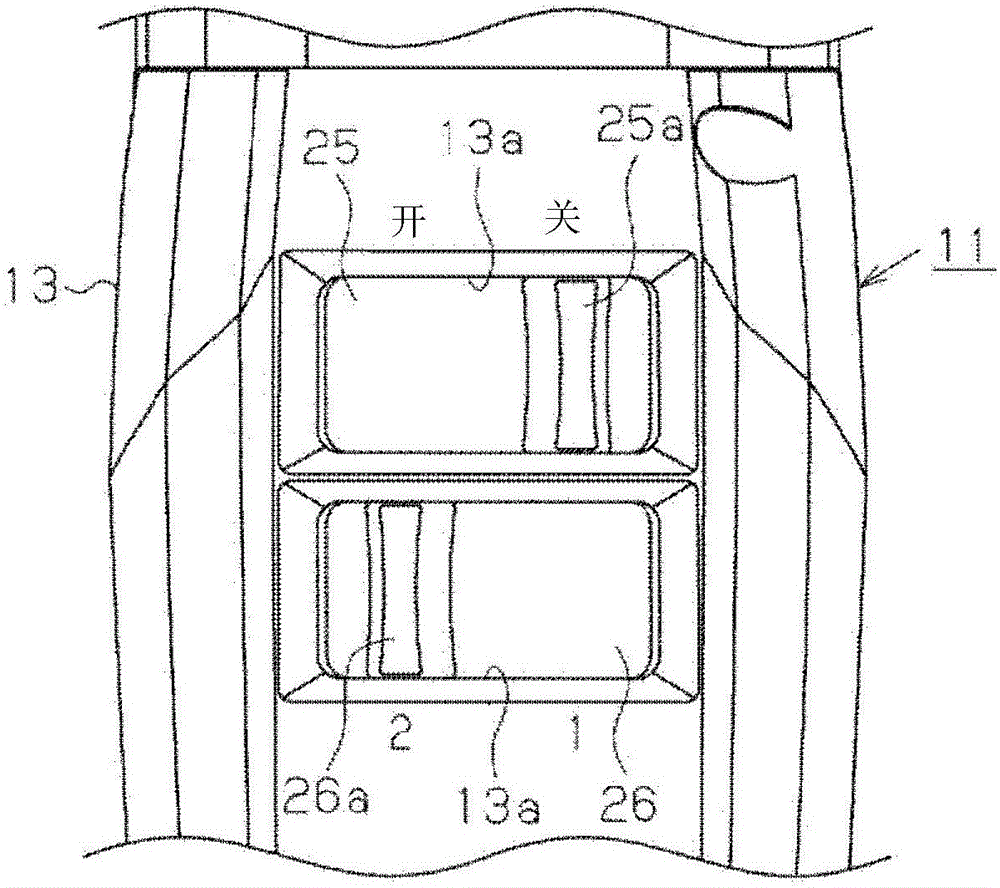

[0034] Below, based on Figure 1 to Figure 12 The first embodiment will be described. figure 1 A power tool 11 as an example of a power tool is schematically shown.

[0035] like figure 1 As shown, the electric power tool 11 of the first embodiment is a hand-held tool that can be held with one hand, and can be used, for example, as an electric drive for concrete. The power tool 11 includes a main body housing 12 as an exterior. The main body casing 12 has a bottomed cylindrical body portion 13 (in the figure 1 Only the left half is shown in the figure) and the handle portion 14 from the body portion 13 to one direction ( figure 1 middle is below) extends out.

[0036] At the base end side of the body portion 13 within the body portion 13 (at the figure 1 The motor 15 is accommodated at a position on the left side). The motor 15 includes an output shaft 16 having an axis of rotation that coincides with the axis of the body portion 13 and is directed toward the front...

no. 2 approach )

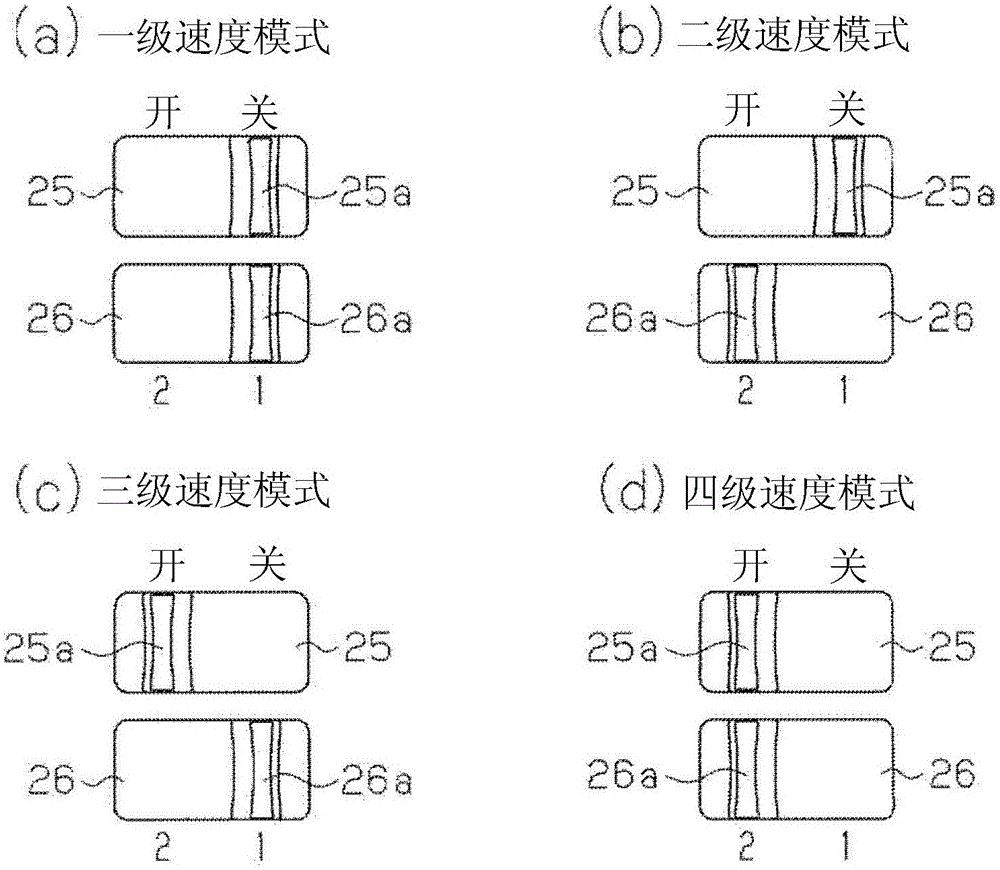

[0087] Next, use Figure 13 to Figure 17 The second embodiment will be described. In this second embodiment, the configuration of the speed change switching mechanism portion 31 of the first embodiment is changed. Hereinafter, the same reference numerals are assigned to the same components as those of the first embodiment, and descriptions thereof will be omitted. In addition, in Figure 13 , Figure 16 as well as Figure 17 In the transmission gear mechanism 30, only the ring gears 42 and 46 that move during shifting are shown, and the other gear groups are omitted.

[0088] like Figure 13 and Figure 14 As shown, the speed change switching mechanism portion 71 of the second embodiment is provided between the respective operation portions 25 and 26 and the speed change mechanism portion 17, and can convert the operation force of the respective operation portions 25 and 26 in the direction around the thrust axis into the thrust axis The force in the axial direction is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com