Oiler for capsule production system

A technology of capsule production system and oiling machine, which is applied in the direction of coating, liquid coating device on the surface, etc. It can solve the problems of uneven oiling and complex structure, and achieve uniform oiling, uniform oiling, and oiling uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

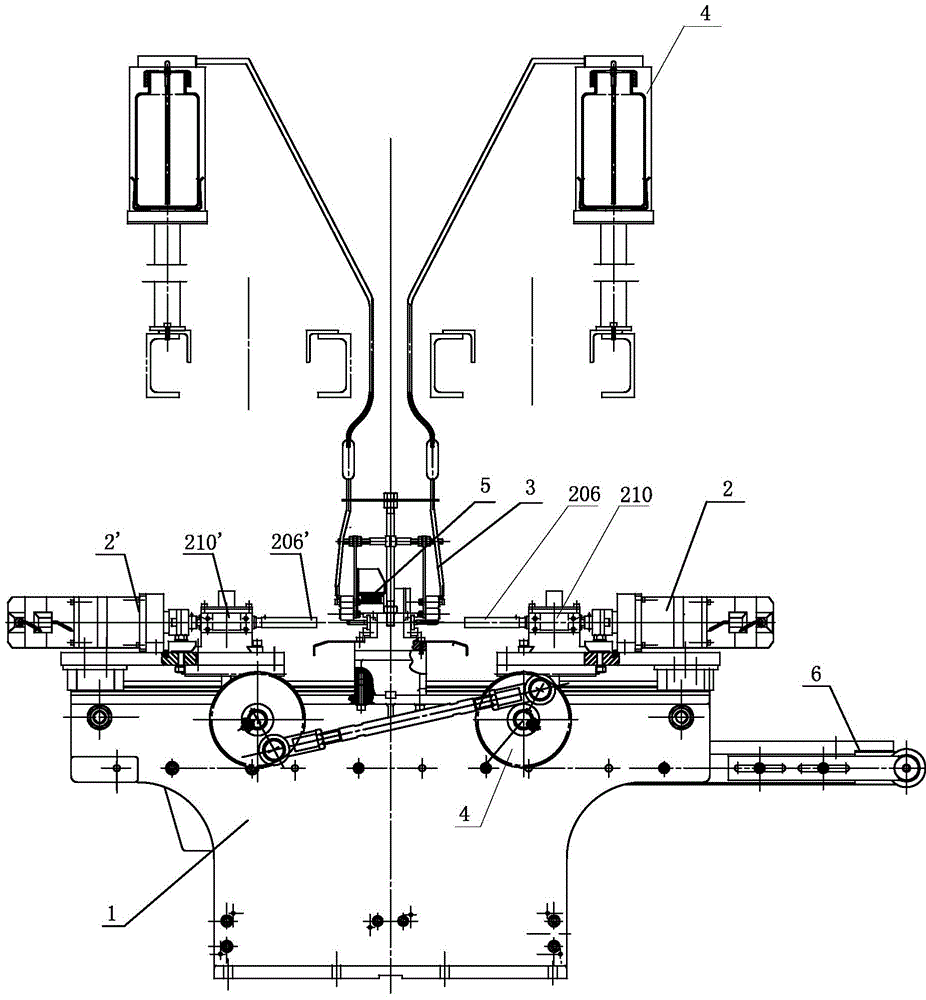

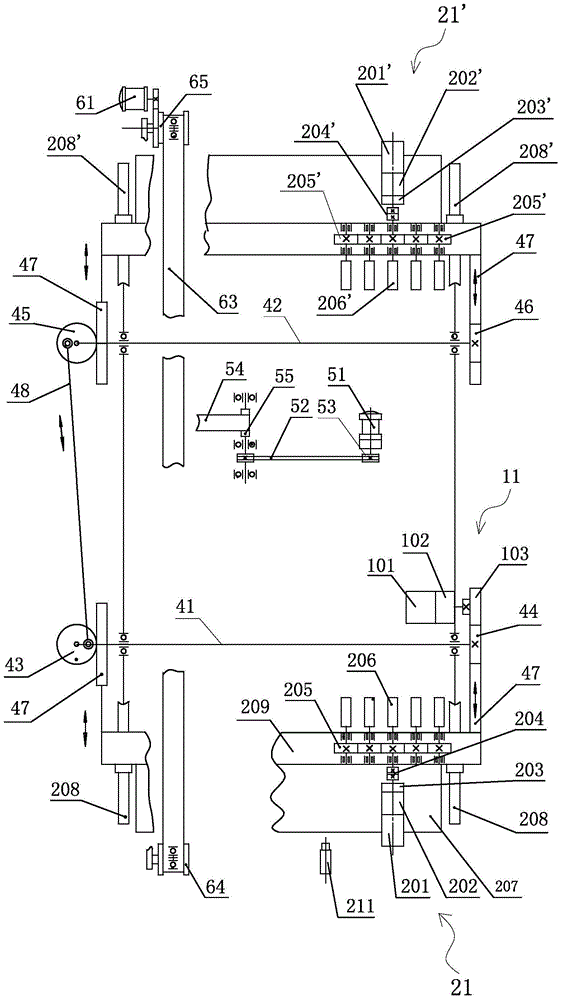

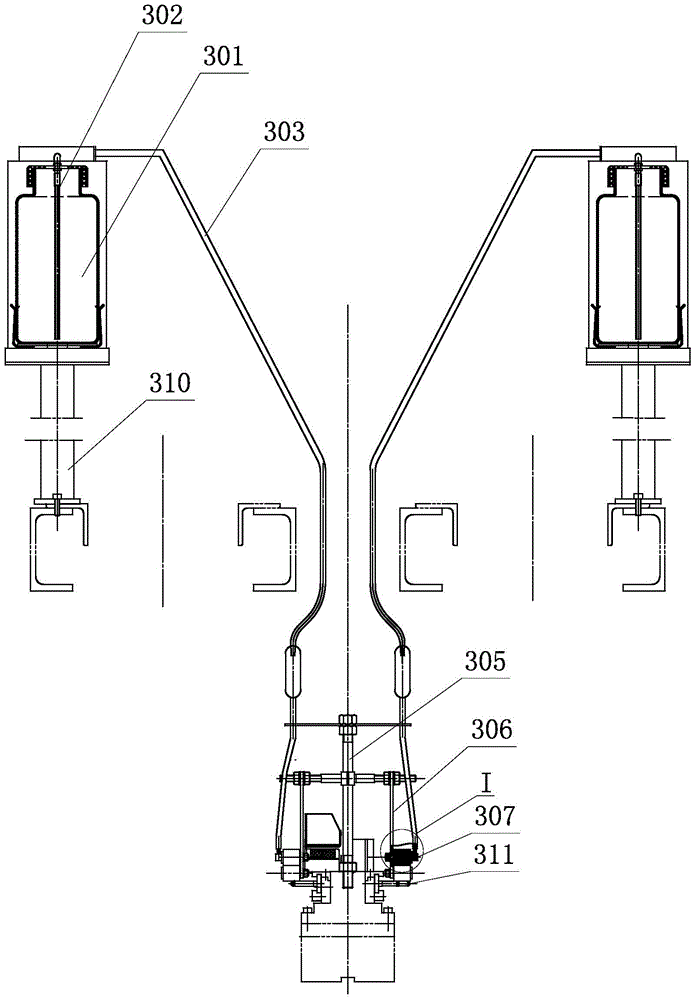

[0033] Example: such as figure 1 As shown, the present invention includes an oiler casing 1, a first driving device 11, a cap rotation transmission system 2 and a body rotation transmission system 2' symmetrically placed on the oiler workbench, an oiler 3, a swing device 4 and The T-shaped slide rail 7 for transporting mold strips, the swing device 4 is connected to one side of the oiler casing 1, the oiler 3 is placed above the workbench, and the oiler end is respectively connected to the capsules on the workbench when oiling. The mold needle 311 of the cap and the capsule body is in contact, and the oiling pipes of the cap rotation transmission system 2 and the body rotation transmission system 2' are coaxial with the mold needle 311 and are respectively matched correspondingly; the first driving device 11 respectively passes The swinging device 4 is connected with the cap rotation transmission system 2 and the body rotation transmission system 2' to drive them to run, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com