Manufacturing device of rubber part

A technology for rubber parts and manufacturing devices, which is applied in the field of manufacturing devices for rubber parts to achieve the effects of small manufacturing devices, preventing changes in physical properties, and preventing long-term exposure to air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, one embodiment of the present invention will be described based on the drawings.

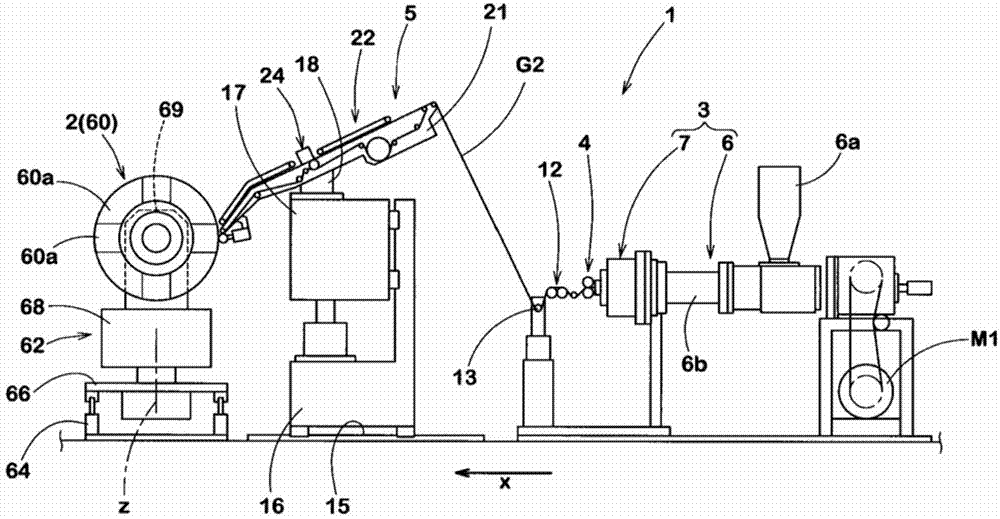

[0025] Such as figure 1 As shown, the rubber member manufacturing apparatus 1 of the present embodiment supplies and winds a belt-shaped rubber belt G2 made of unvulcanized rubber on the outside of a rotatable substantially cylindrical wound body 2 to manufacture an air-filled body. A device for ring-shaped rubber parts for tires. The rubber member includes at least an inner liner, a tread rubber, a side rubber, and the like, although not particularly limited.

[0026] The manufacturing device 1 of the present embodiment has a rubber extruder 3 , a calender head 4 , and a rubber applicator 5 .

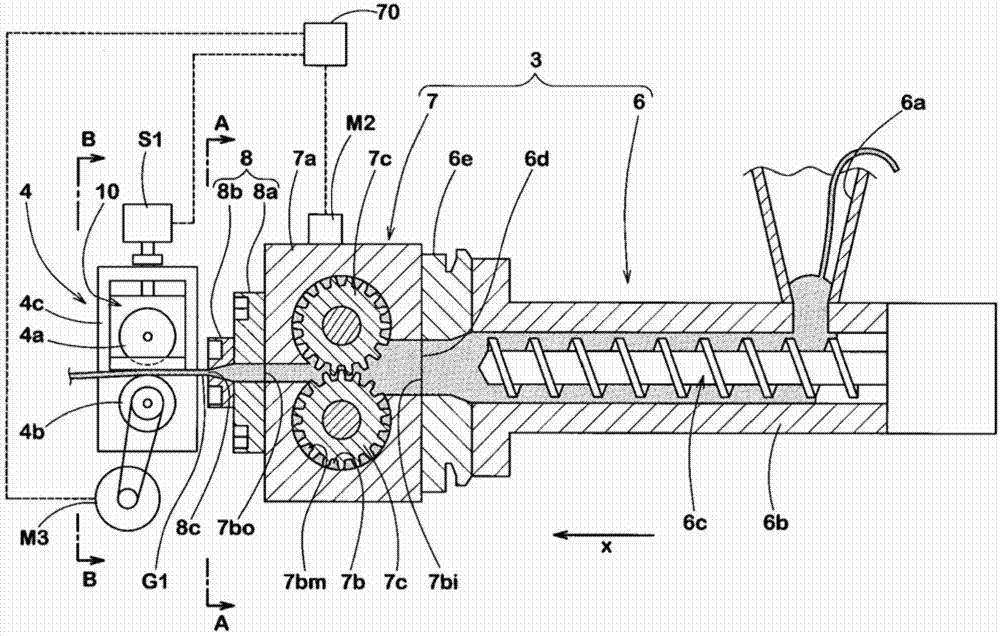

[0027] figure 2 A partial sectional view of the rubber extruder 3 is shown. The rubber extruder 3 includes a rubber extruder body 6 and a gear pump 7 connected to a discharge port 6 d of the rubber extruder body 6 .

[0028] The main body 6 of the rubber extruder includes: a su...

PUM

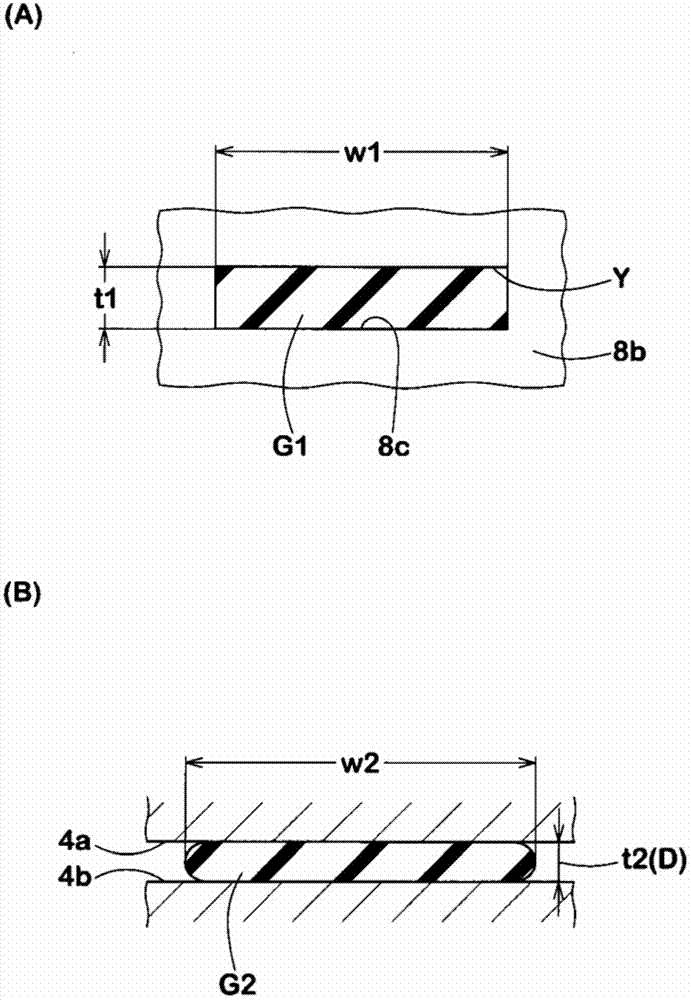

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com