A method for prestressing and assembling prefabricated reinforced concrete frames to strengthen existing structures

A technology of reinforced concrete and prestressed tendons, which is applied in building components, building structure, building maintenance and other directions to achieve the effect of reducing negative environmental impact, reducing wet work and good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

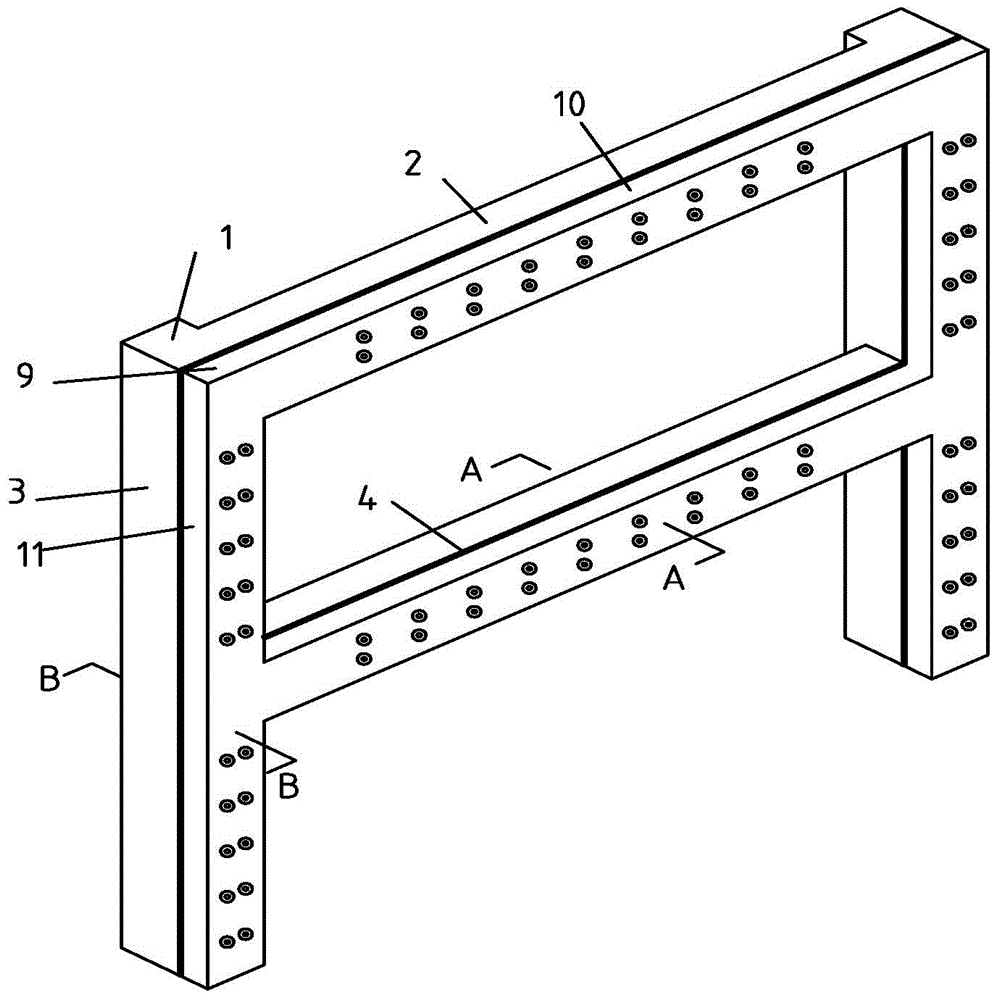

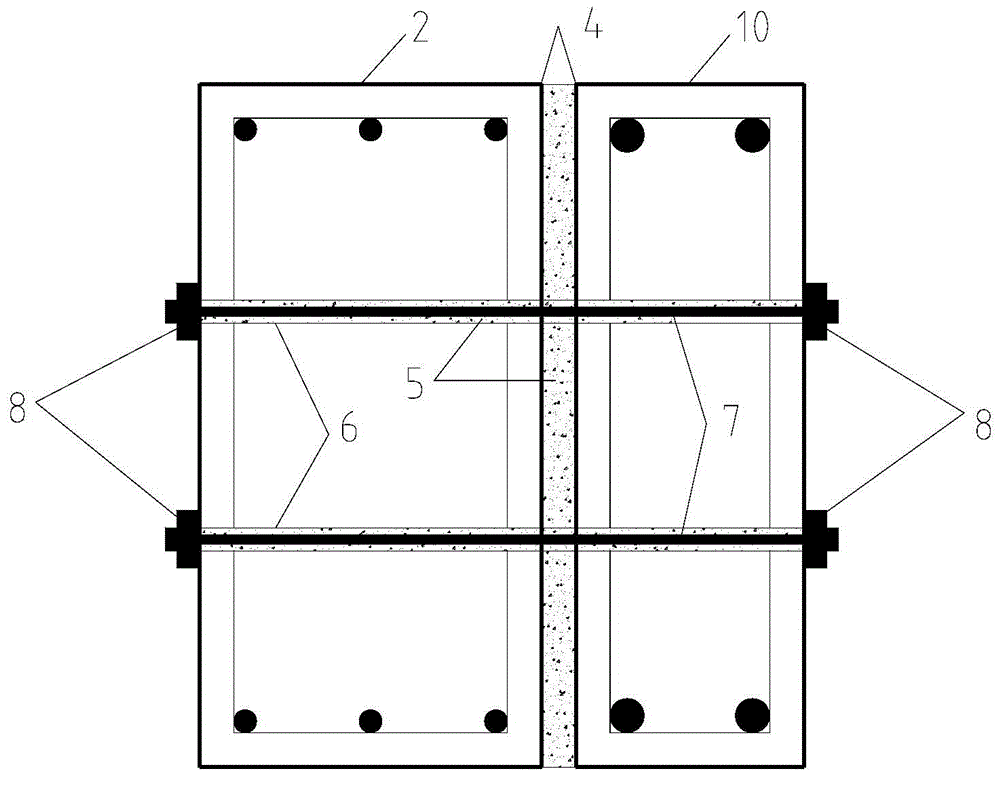

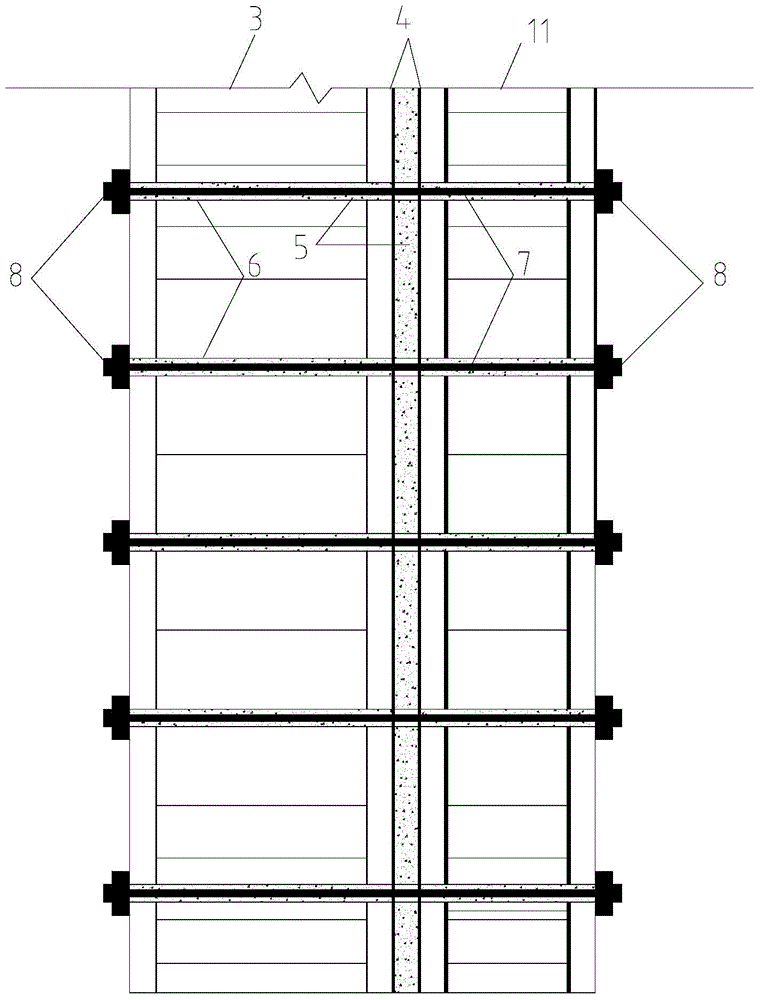

[0015] Step 1: According to the original reinforced concrete frame to be reinforced 1, "Code for Design of Concrete Structures" (GB50010-2010), "Code for Seismic Design of Buildings" (GB50011-2010), determine the newly added prefabricated frame beams 10 and newly added prefabricated frame columns 11 The size of the section, the amount of reinforcement, the strength level of the concrete, and the position of the channel 6 of the unbonded prestressed tendon. The tunnel 6 is arranged in two parallel rows along the height direction of the original frame column 3 and the newly added prefabricated frame column 11, and the span direction of the original frame beam 2 and the newly added prefabricated frame beam 10 is every 500-1000mm, and the position should avoid the original frame beam 2, The plastic hinge area at the end of the prefabricated frame beam 10 and the beam-column node area should be added, and the original frame column 3, the newly added prefabricated frame column 11, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com