High-pressure hydrogen environment material testing machine fatigue test fixture

A material testing machine and fatigue testing technology, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve problems such as easy loosening, unfastened sample clamping, and large and complex structures, so as to avoid loosening and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

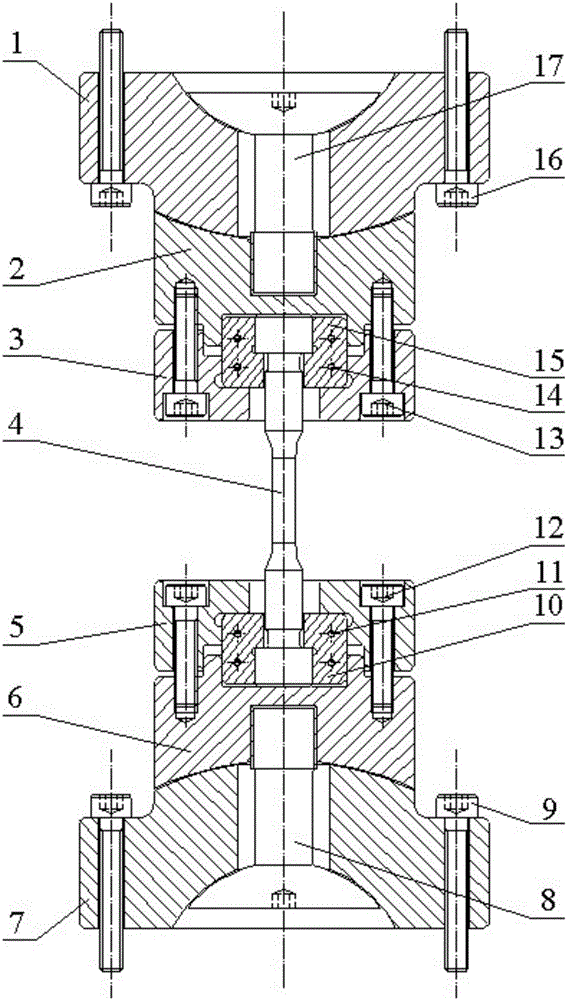

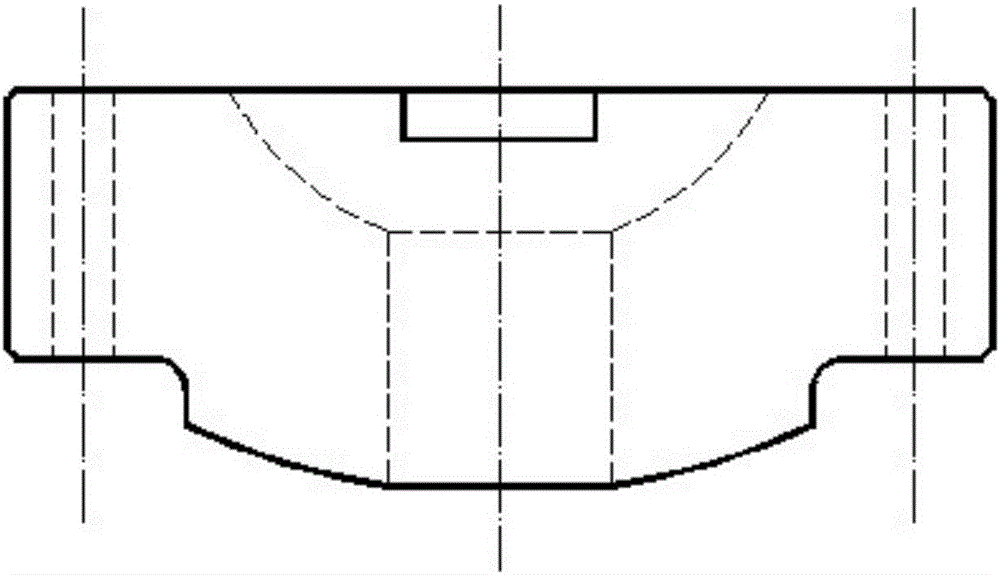

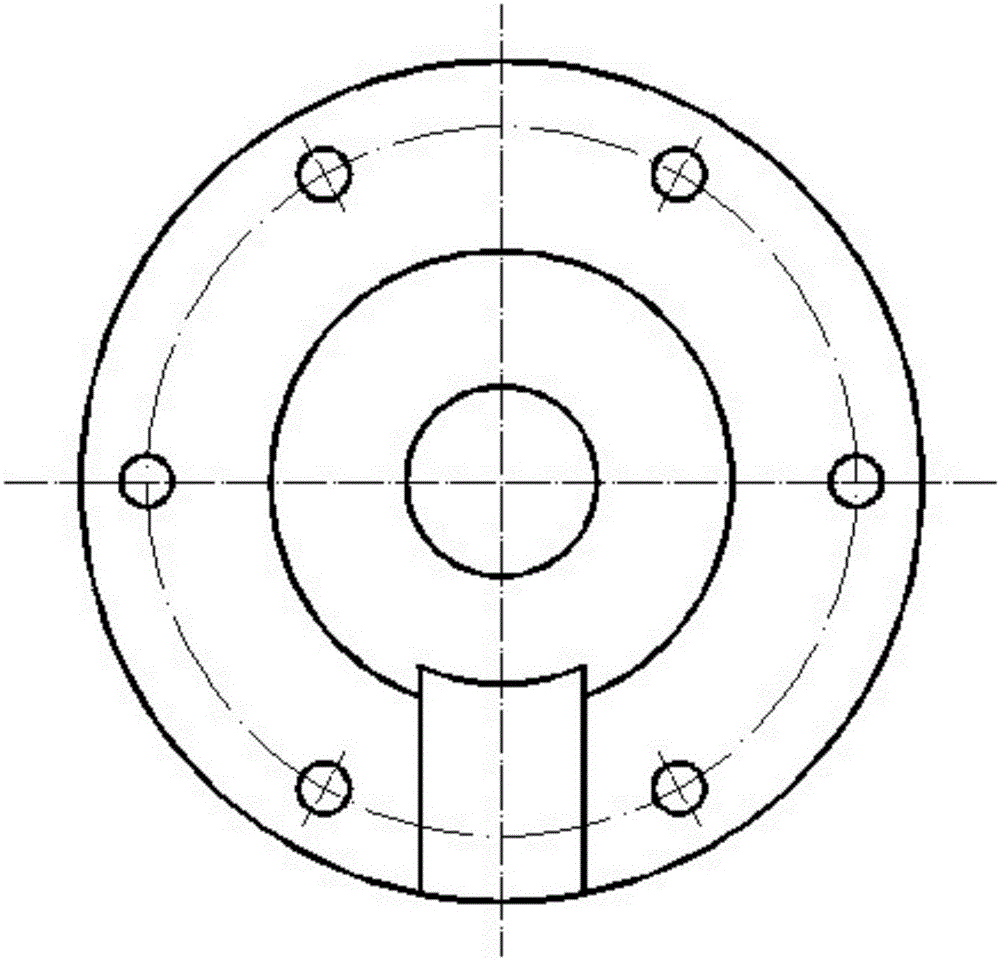

[0023] Such as figure 1 As shown, a high-pressure hydrogen environment material testing machine fatigue test fixture is divided into two parts, the upper fixture and the lower fixture; the upper fixture is composed of an upper support 1, an upper connecting rod 17, an upper connecting plate 2, an upper chassis 3, and an upper locking The upper support 1 has a through hole in the center and a screw hole on the outer periphery to connect with the upper end of the testing machine through a screw 16, one end has a spherical cavity inward, and the other end has a spherical curved surface outward; the upper connection The upper end of the rod 17 is provided with a spherical crown body, and its spherical outer surface cooperates with the spherical surface of the inner cavity of the upper support 1 to form a spherical hinge rotary pair. It is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com