Process for forming side boards of backrests of automobile seats

A technology of car seat and forming process, which is applied in the field of hardware forming, can solve problems such as wrinkles in the flanging process, achieve the effects of increasing drawing depth, reducing shear stress, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, specific embodiments of the present invention will be described in conjunction with the accompanying drawings.

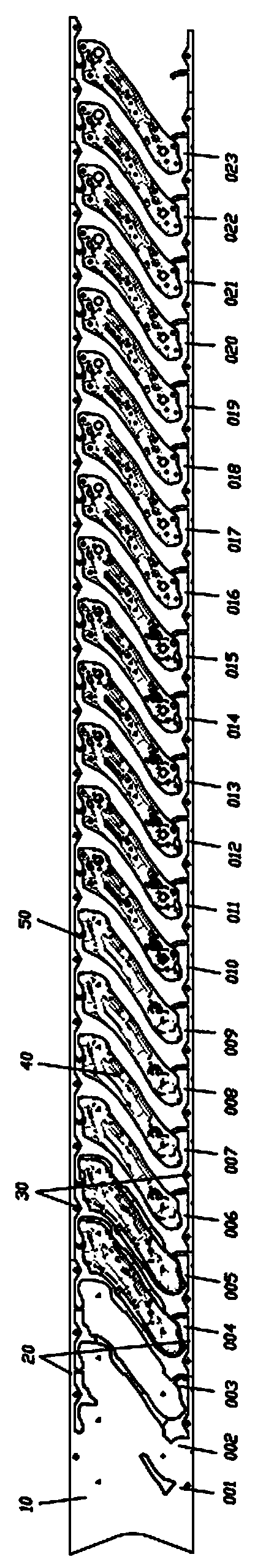

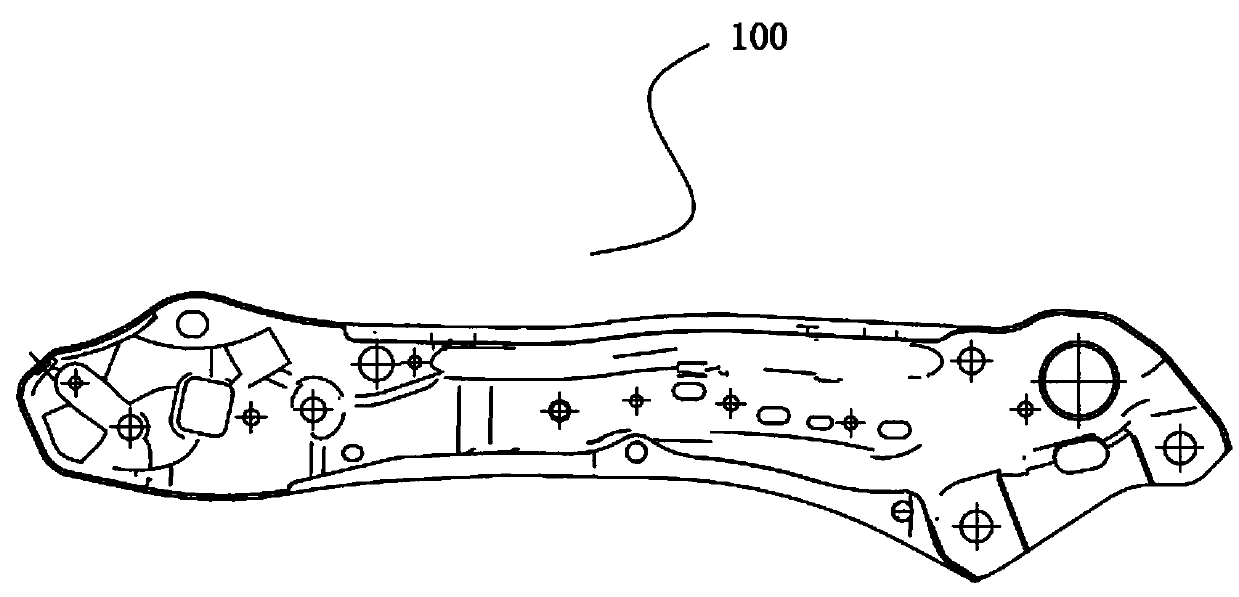

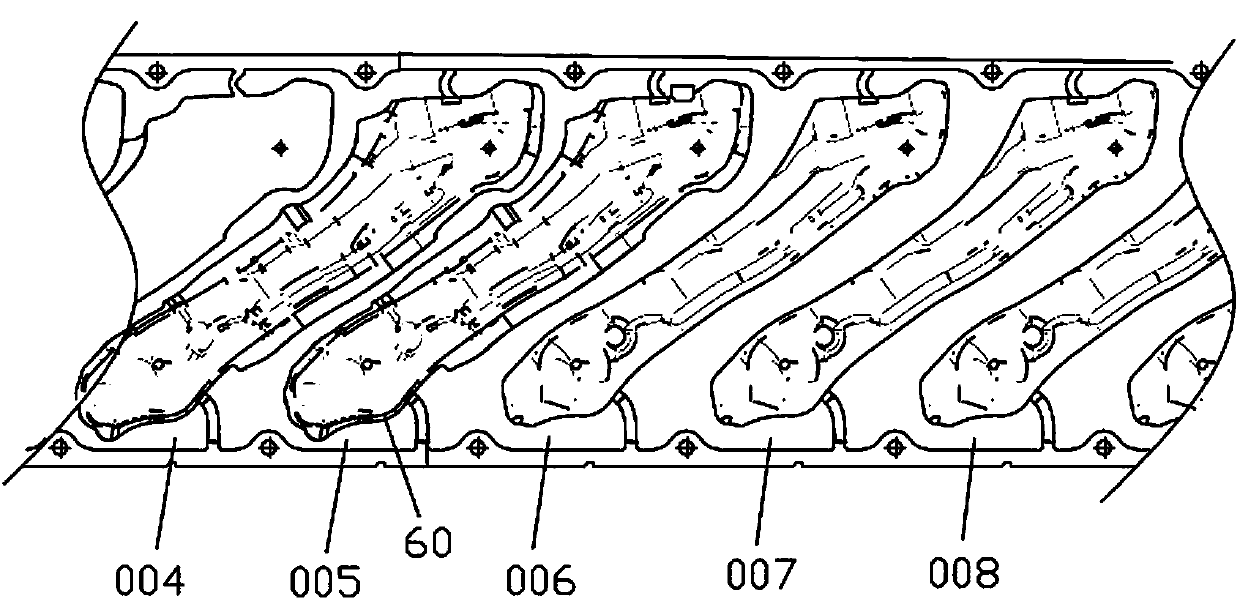

[0029] Such as Figure 1 to Figure 4 As shown, the forming process of the side panel of the backrest of the car seat includes the first punching process 001, the incision process 002, the trimming process 003, the drawing process 004, the first empty station 005, and the downward flanging process 006 , the second empty station 007, the side shaping process 008, the third empty station 009, the second punching process 010, the first hole turning process 011, the side punching process 012, the fourth empty station 013, the fifth empty station Station 014, sixth empty station 015, first side flanging process 016, seventh empty station 017, second side flanging process 018, eighth empty station 019, second hole turning process 020, ninth Empty station 021, shaping process 022 and cutting process 023. Each process is realized by the mold unit corresp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com