Positioning plate with turnover beam structure

A technology of positioning plate and turning beam, applied in positioning device, clamping, supporting and other directions to achieve the effect of ensuring positioning accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

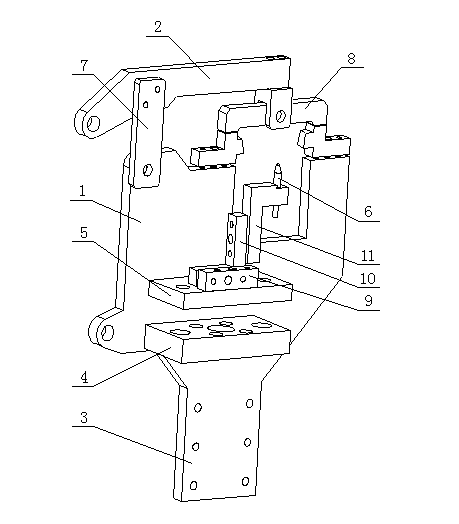

[0009] like figure 1 As shown, the positioning plate of the overturning beam structure in the embodiment of the present invention includes an overturning beam 2 and a positioning plate 1, the bottom of the positioning plate 1 is a connecting plate 3 with a plurality of threaded holes, and the connecting plate 3 is connected to the positioning plate 1. The positioning plate 1 is integrally formed, and a horizontal fixing plate 4 vertically connected with the positioning plate 1 is provided on the top of the connecting plate 3. The horizontal fixing plate 4 is connected with the positioning plate 1 by welding, and is fixed in the horizontal position. The top of the plate 4 is provided with a thimble holder 5, the thimble holder 5 is vertically installed on the positioning plate 1, and the top of the thimble holder 5 is equipped with a thimble 6; The left side of the positioning plate 1 is hinged, and the flip beam 2 is fixedly connected with the support plate 7. The right side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com