On-line key cylinder device

A technology of lock cylinder and wire lock, which is applied in the direction of mold core, casting molding equipment, casting mold, etc., can solve the problems of load capacity limitation, repeated positioning deviation, waste of time, etc., achieve smooth logistics, ensure positioning accuracy and stability, Effect of reducing investment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

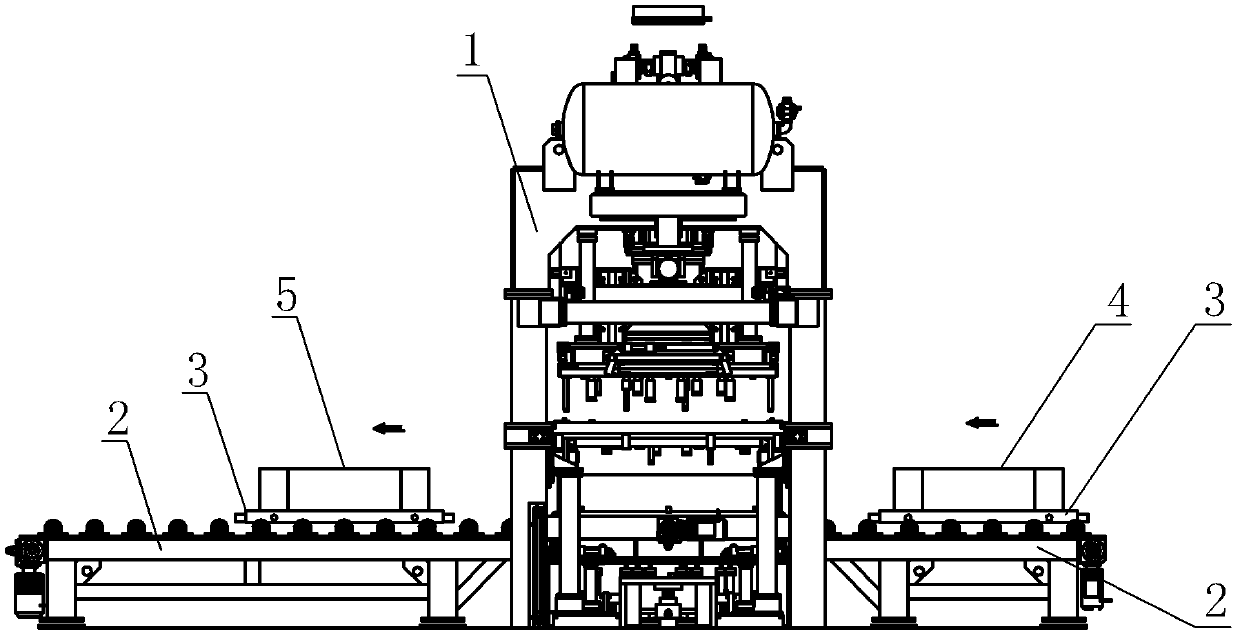

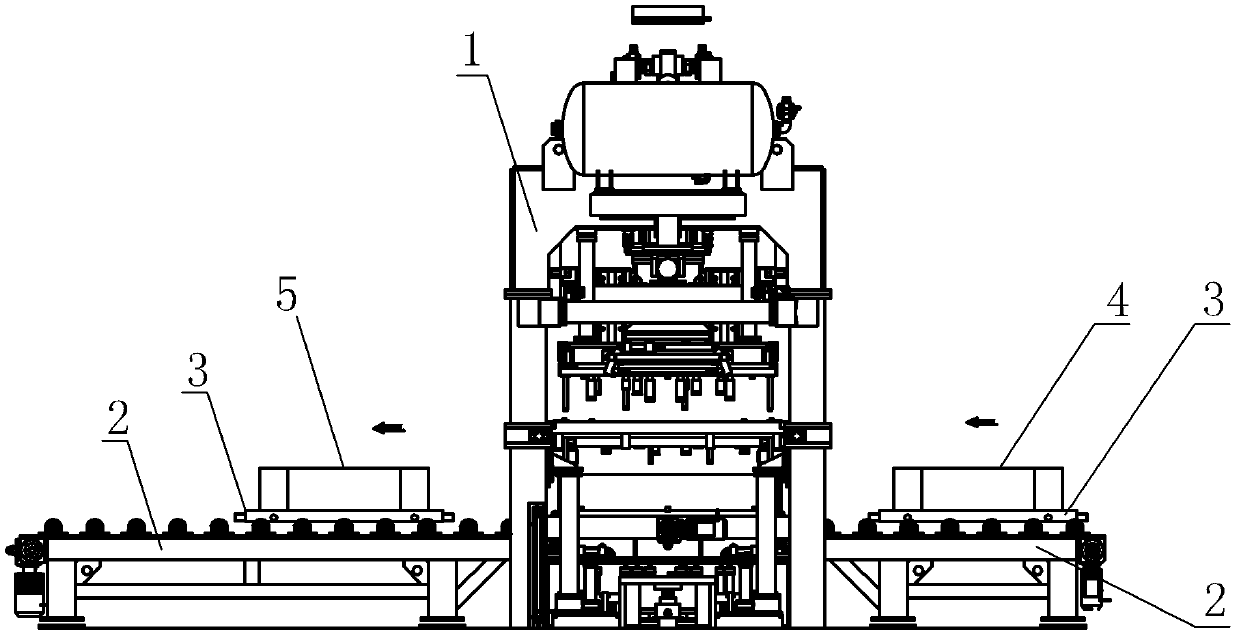

[0011] like figure 1 The online lock cylinder device includes a lock cylinder mechanism 1 and a mechanical raceway 2 , the mechanical raceway 2 runs through the lock cylinder mechanism 1 , and a sand core tray 3 is arranged on the mechanical raceway 2 . The lock cylinder mechanism 1 can be realized by using the existing sand-shooting and blowing structure, which is not the invention point of the present invention, and its structure is not limited here.

[0012] When locking the core, the sand core tray 3 carries the pre-assembled sand core 4 that is transported manually or by a spreader and directly enters the lock core mechanism 1 through the mechanical raceway 2. In the lock core mechanism 1, the sand core tray 3 carries the sand core to complete the core assembly. , and then the sand core tray 2 carries the combined sand core 5 away from the lock core mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com