Clutch device for power tool

A technology for clutch devices and electric tools, which is applied in the field of clutch devices, can solve problems such as reliability needs to be improved, and achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

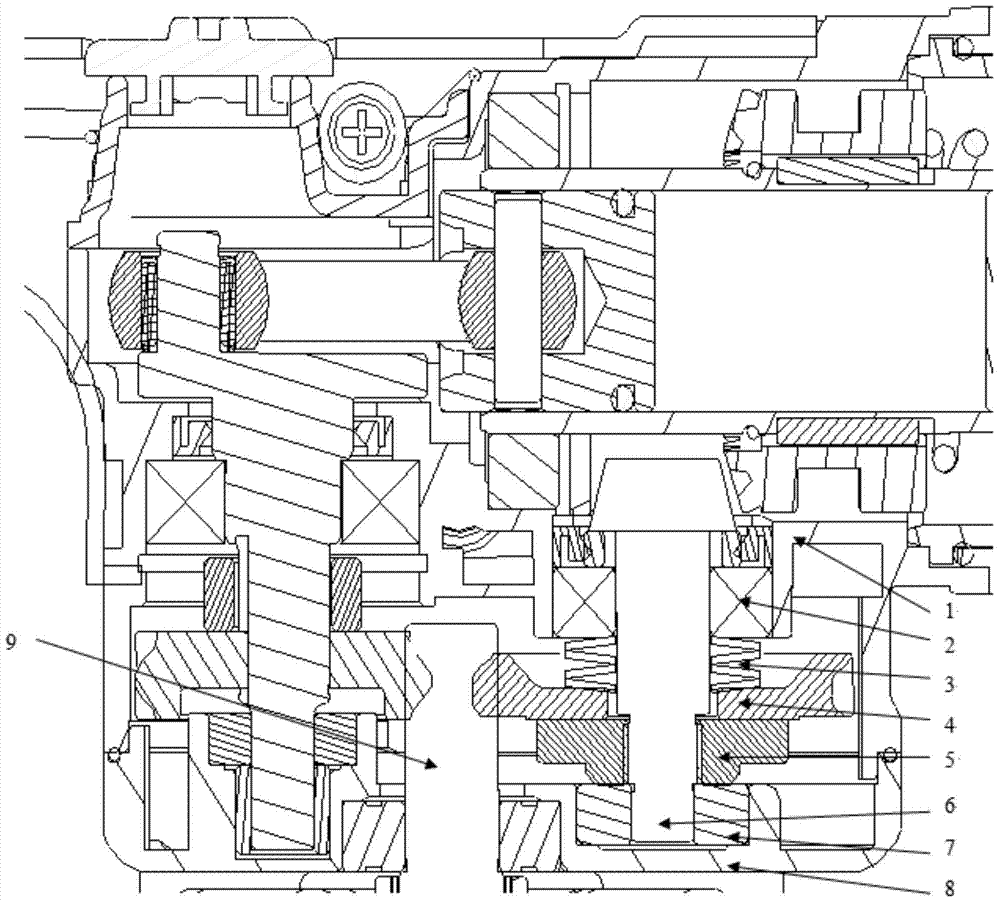

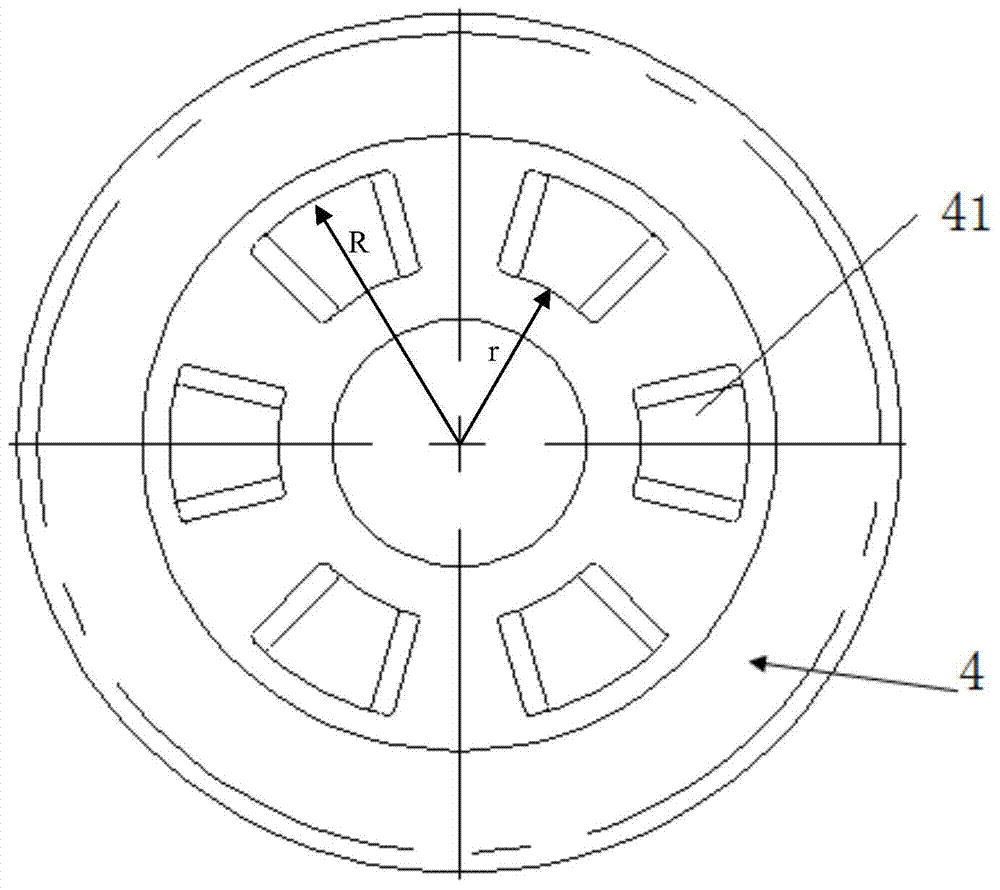

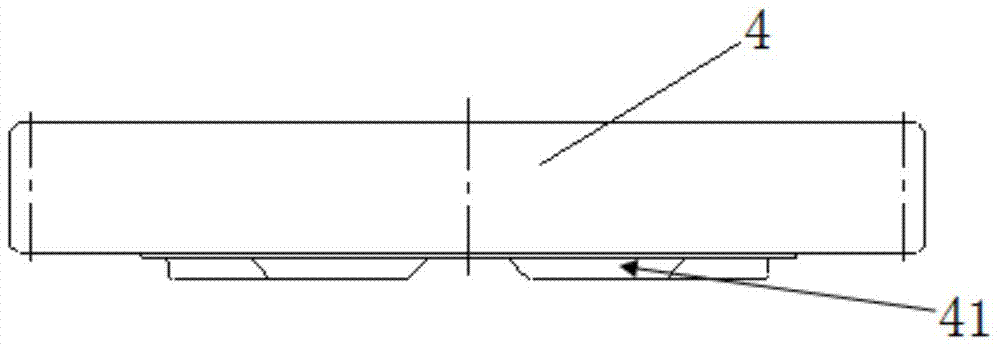

[0019] Such as Figure 1 to Figure 5 As shown, the clutch device of the electric tool includes: a reduction box 1, a second bearing 2 installed on the reduction box 1, a small shaft 6 passing through the second bearing 2, and a butterfly spring 3 is sleeved on the small shaft 6, The clutch gear 4 and the clutch block 5, the clutch block 5 and the small shaft 6 are screwed together, the clutch gear 4 is pressed on the clutch block 5 by the butterfly spring 3, and the clutch gear 41 and the clutch block 5 provided by the clutch gear 4 The clutch teeth 51 of the clutch block arranged on the top mesh with each other, the clutch gear 4 meshes with the gear of the armature 9 mounted on the middle cover 8 , and the small shaft 6 is fixed on the middle cover 8 through the first bearing 7 .

[0020] Such as figure 1 As shown, the armature 9 rotates, the gear meshes to drive the clutch gear 4, the clutch gear 4 drives the clutch block 5, and the clutch block 5 drives the small shaft 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com