Drilling anchoring pre-supporting system based on shield operation and construction method

A pre-support and anchoring technology, which is applied in earth-moving drilling, installation of bolts, mining equipment, etc., can solve the problems of affecting the quality of anchoring, low drilling efficiency, and scrapping of anchoring holes, so as to increase the stability of anchoring and improve drilling. Efficiency and the effect of improving anchorage quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

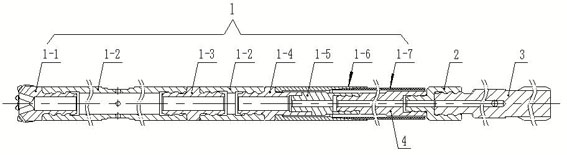

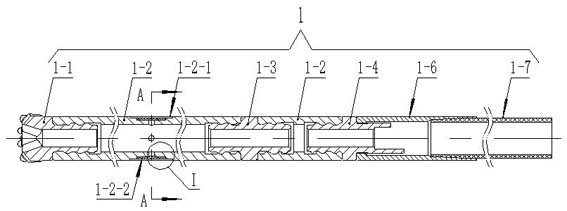

[0043] Such as Figure 1-8 As shown, the drilling anchoring pre-support system provided by the present invention is composed of an anchor rod 1 connected with a shank shank 3 through an MF quick-change drill rod 4 .

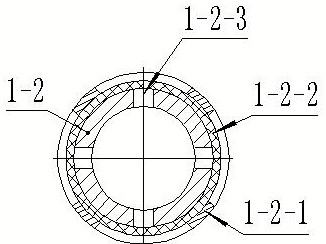

[0044]Among them, the MF quick-change drill rod 4 is a hollow rod-shaped structure with an external thread at one end and an internal thread at the other end; the drill tail 3 is a standard drill tool. The anchor rod 1 consists of an anchor pipe with a number of grouting holes 1-2-3 distributed on the surface and internal threads at both ends, a rock drill bit 1-1 connected to the front end of the anchor pipe through external threads, and a lock joint through the nozzle. It consists of a pipe boot 1-6 connected to the tail end of the anchor pipe and a PVC pipe 1-7 fixedly connected with the pipe boot. The nozzle lock joint is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com