Small-section anchoring and rock drilling integrated machine

A small-section, all-in-one technology, which is applied in the fields of anchoring and protecting engineering machinery and rock drilling in mine roadways, can solve the problems of cumbersome operation, increase of production cost, labor intensity of workers, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

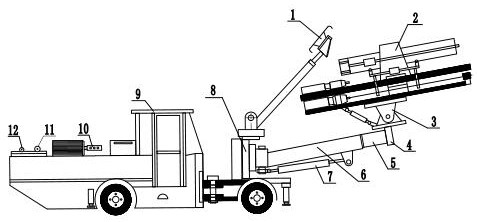

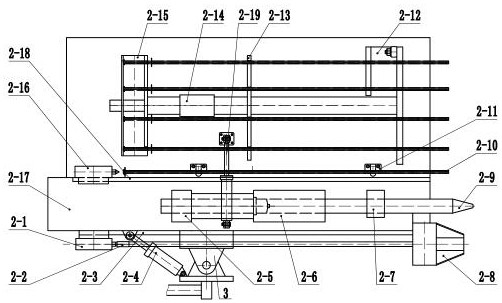

[0045] refer to Figure 1-Figure 4 , the small-section anchor-protection rock-drilling integrated machine of the present invention includes a net-hanging manipulator 1, a drill-anchor carriage device 2, a drill pipe loading and unloading manipulator, a drill pipe adjustment device for blasting holes, a hydraulic control device, and a temperature control device, oil-electric dual-purpose Conversion device, drill bit cooling and slag cleaning device, including:

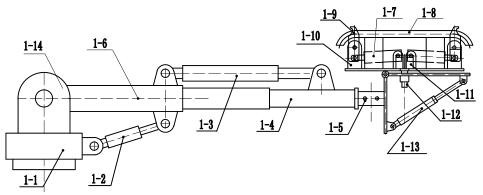

[0046] Hanging net manipulator: refer to figure 1 , figure 2

[0047] The net hanging manipulator is used to realize the mechanical net hanging, and is lifted by the boom to the installation position of the anchor net, and cooperates with the drilling and anchor sliding frame device to realize the anchor protection of the anchor net and anchor bar.

[0048] Such as Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com