An ultra-low temperature loading and unloading arm structure with overflow prevention pipeline

An ultra-low temperature, loading and unloading arm technology, used in packaging, distribution devices, transportation and packaging, etc., can solve the problems of the loading and unloading arm lack of overflow prevention system, unable to achieve low temperature sealing requirements, safety hazards and other problems, to solve the problem of uneven deformation of the sealing surface, The effect of solving low temperature sealing problems and eliminating safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

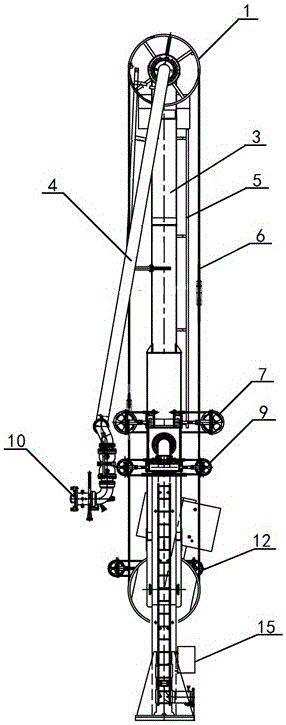

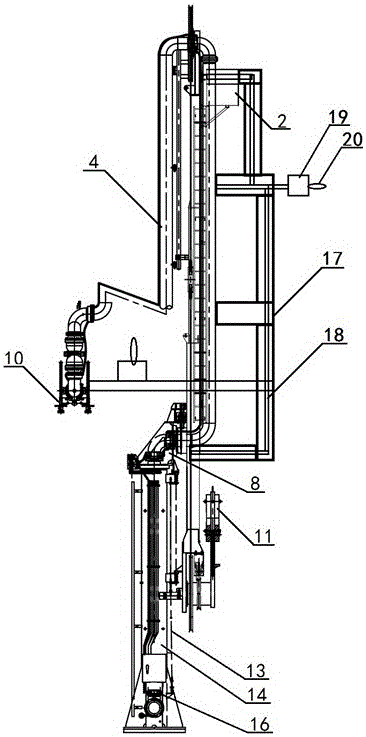

[0017] like Figure 1-2 As shown, the ultra-low temperature loading and unloading arm structure with overflow prevention pipeline described in the embodiment of the present invention includes the upper sheave and the outer arm support assembly 1, the trunnion box 8, the column 14 and the nitrogen purging device 16, and the column 14 The upper and lower ends are respectively installed with the upper sheave and the outer arm support assembly 1, and the nitrogen purge device 16, which is located at the center of the upper sheave and the outer arm support assembly 1 and is connected to the outwardly extending process pipeline 4, and the process pipeline 4 is A three-dimensional joint 10 is installed at the end of the three-dimensional joint 10, and an emergency release device is provided on the surface of the three-dimensional joint 10; a support box 3 is arranged between the upper sheave and the outer arm support assembly 1 and the column 14, and the upper sheave and the outer arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com