Secondary vibration-damping type rubber spring structure for active suspension

A technology of active suspension and rubber spring, applied in the field of rubber spring structure, can solve problems such as short life and unsatisfactory performance of rubber spring, and achieve the effect of improving performance, solving uneven deformation, and improving service life and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

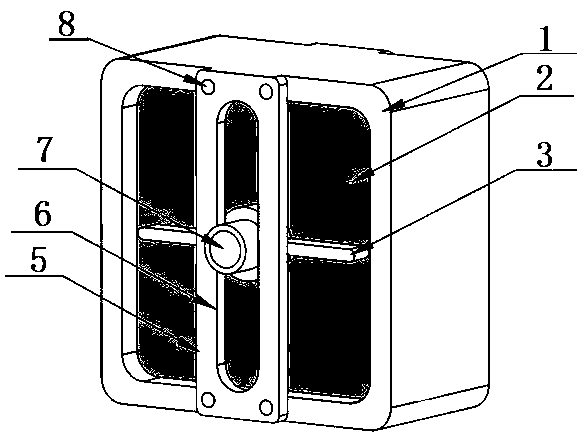

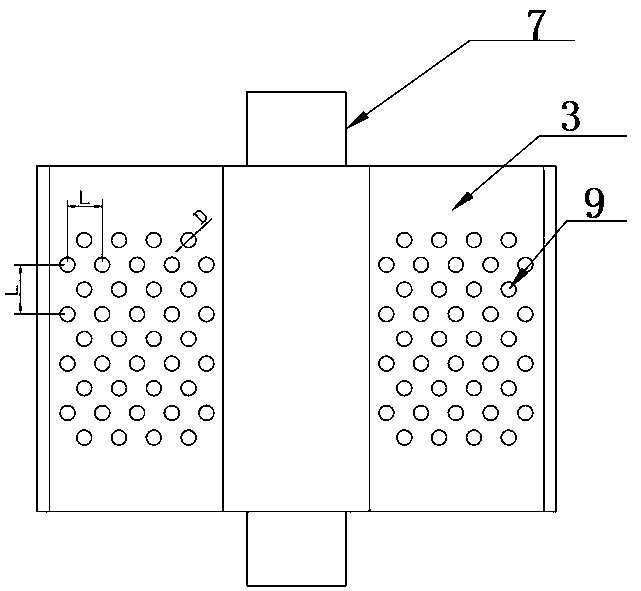

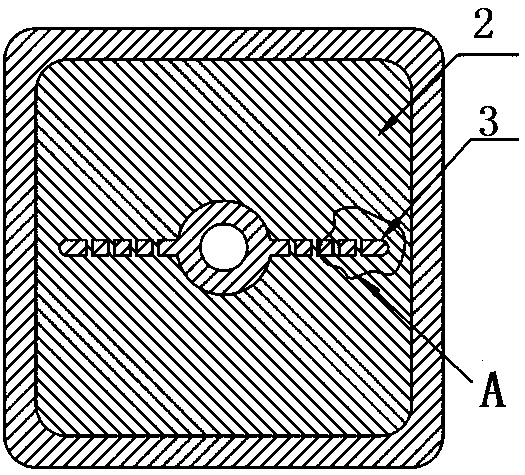

[0019] Such as figure 1 As shown, the outermost part of the present invention is a rigid outer ring 1, the upper end of the rigid outer ring 1 is fixedly connected to the lower end of the inner cylinder of the active force actuator in the active suspension, and the present invention is connected in series to the active force actuator . In the middle of the rigid outer ring 1, there is a square through hole through the front and rear. The square elastic main spring 2 is accommodated in the middle of the square through hole. The shape of the rubber main spring 2 is consistent with the shape of the square through hole. The rubber main spring 2 is fixedly connected with the square through hole, and the center of the rubber main spring 2 coincides with the center of the rigid outer ring 1. The front and rear of the rigid outer ring 1 are fixedly connected with a rigid guide rail 5 vertically up and down. The two rigid guide rails 5 are symmetrical front and back, and there is a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com