Method for manufacturing inserts for electronic passports

一种制造方法、插件的技术,应用在机器使用的记录载体、计算机零部件、仪器等方向,能够解决制造效率下降等问题,达到避免装卸的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

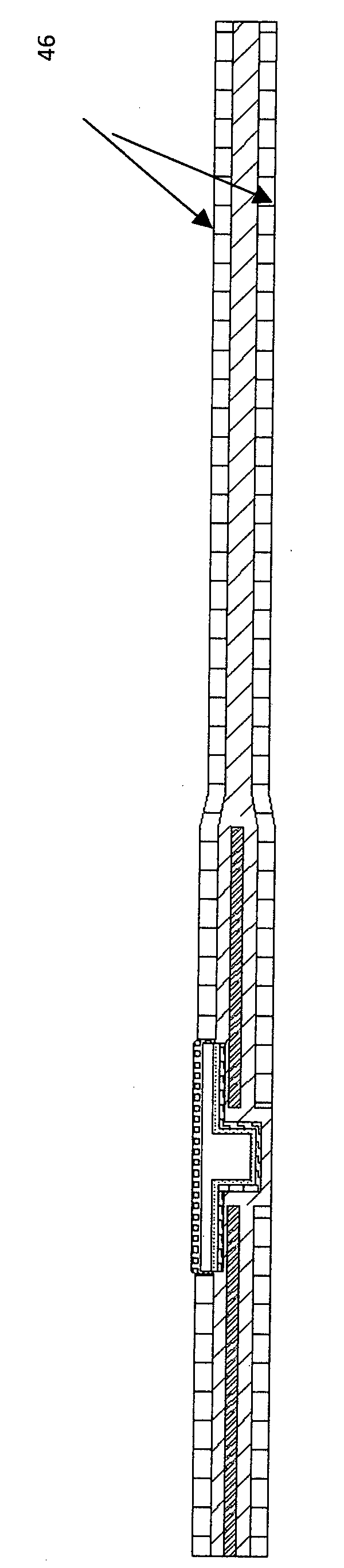

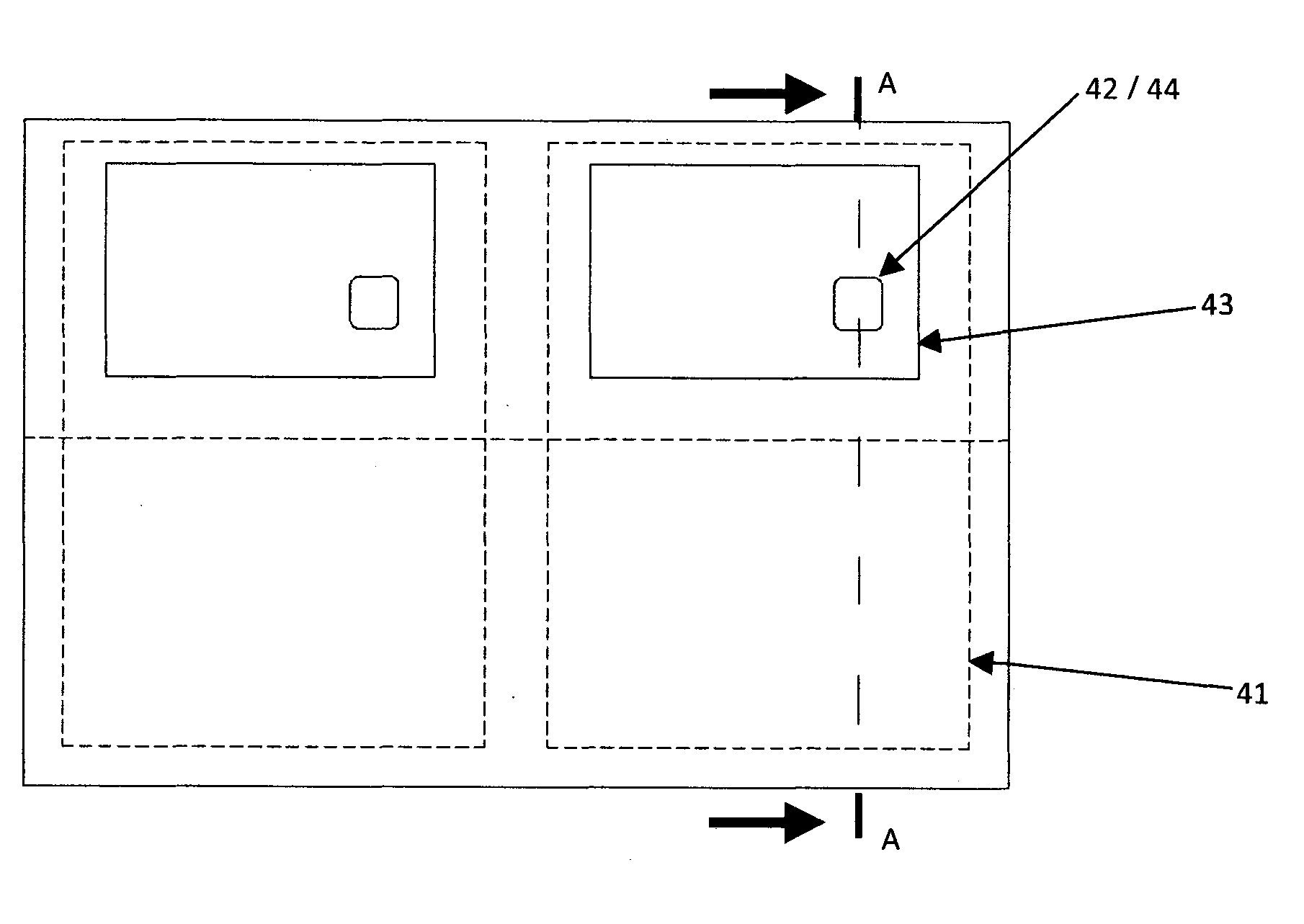

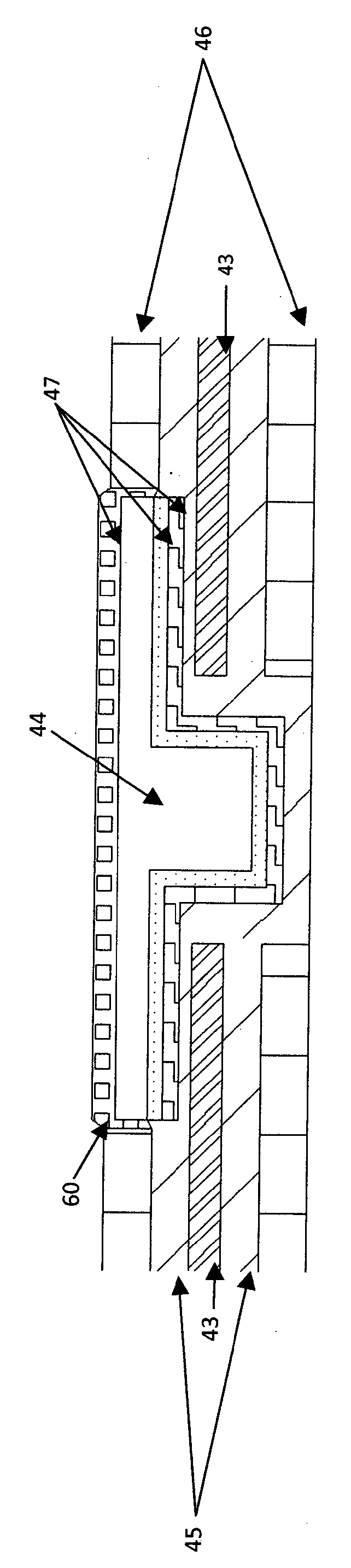

[0040] refer to figure 1 . In this figure a flow chart of a classical method for producing an electronic insert for a security document is shown. The first parallel steps 10, 11, 12 consist in providing the parts to be assembled, i.e. sheets or rolls of adhesive (step 10), substrate sheets of paper or plastic (step 11), antennas (step 12) and An electronic module (provided at step 13), the antenna is usually in the form of a very thin sheet with a metal antenna screen printed or stamped, printed, or even cousued (cousu) added to, the electronic module essentially A packaged electronic chip and a contact section for contacting a corresponding section of the antenna are included.

[0041] After the stage (10, 11, 12, 13) of providing components, some of which are presented in a format corresponding to several plugins (this is especially the case for carriers, which are presented in the form of pages of large size) , the part cutting (steps 14, 15, 16) is performed in order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com