A kind of all-steel radial tire reinforced outside the bead and its preparation method

A radial tire and external reinforcement technology, applied in tire parts, reinforcement layers of pneumatic tires, tires, etc., can solve the problem of serious homogeneity of all-steel truck radial tires, achieve convenient production and implementation, and improve the durability of the bead. , the effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

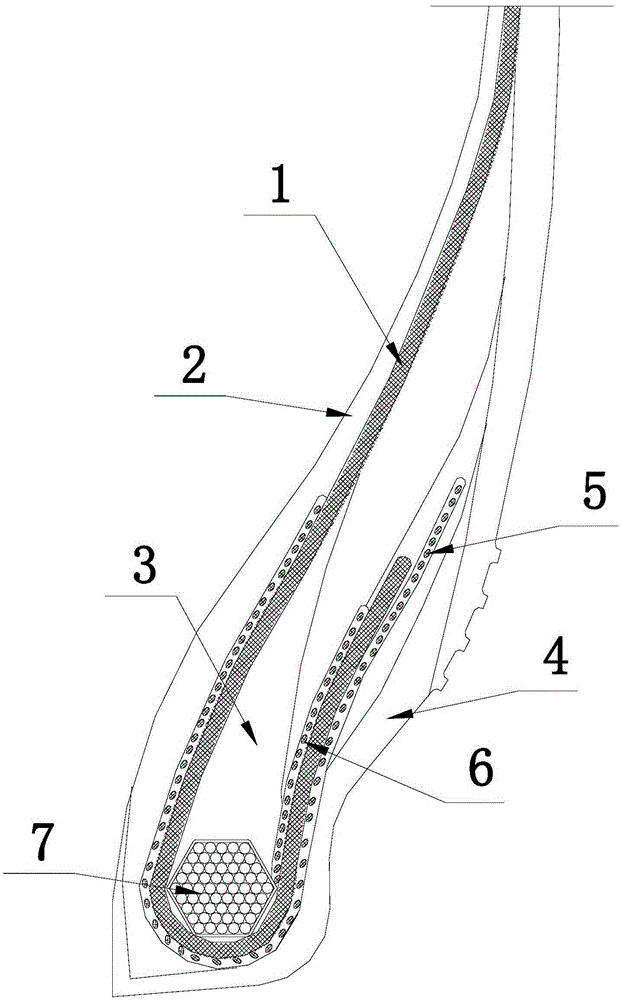

[0031] An all-steel radial tire reinforced outside the bead, the tire includes a tire crown, a tire shoulder, a carcass cord layer 1, an inner liner layer 2, a belt layer and a tire bead. Such as figure 1 As shown, the bead includes a bead 7, an apex 3 and a spigot protector 4, the carcass ply 1 is turned up to the bead 7, and the two sides of the carcass 1 are respectively provided with steel cords. Cladding layer 5 and steel cord reinforcement layer 6. The steel cord turn-up layer 5 is fitted between the carcass ply 1 and the inner liner 2, the steel cord turn-up layer 5 bypasses the traveler 7 and has a U-shaped section, and the steel cord turn-up layer 5 Both the inner end point and the outer end point are higher than the turn-up end point of the carcass ply 1, the level difference between the outer end point of the steel c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com