Motorcycle tire and manufacturing method thereof

A manufacturing method and motorcycle technology, applied to tire components, reinforcement layers of pneumatic tires, tires, etc., can solve problems such as transitional performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

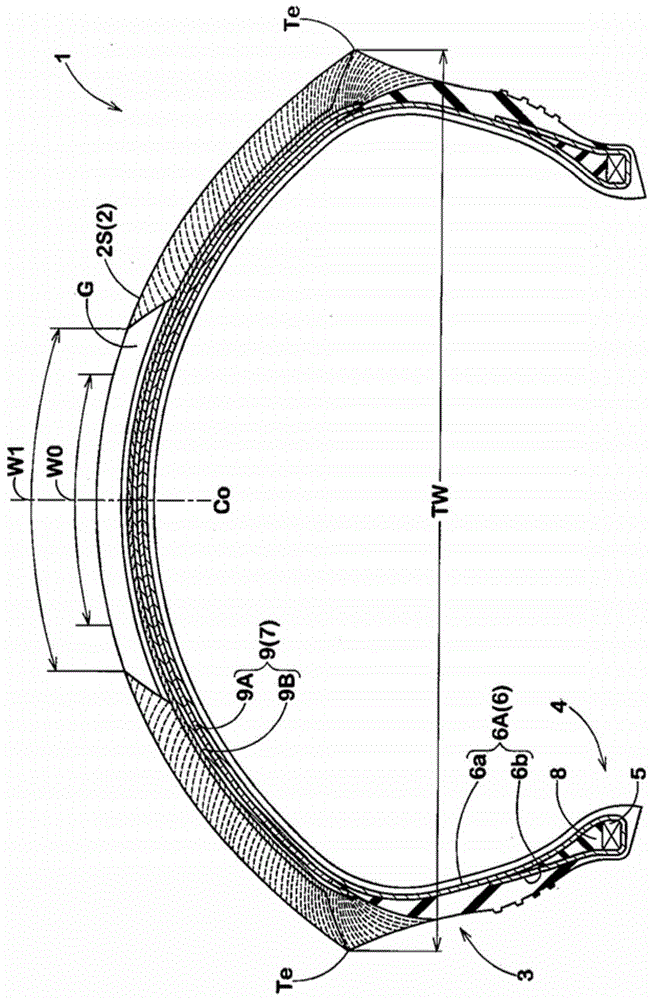

[0073] (A) According to the specifications in Table 2, a prototype with figure 1 The tire size shown in the internal structure is a motorcycle tire of 180 / 55R17, and the handling stability, rolling resistance performance and transition characteristics of the test tire are tested. Figure 8 (A)~ Figure 8 (D) shows the tread rubber structure of each tire, and Table 1 shows the tangent loss values tanδ, complex elastic modulus E*, silica compound ratio.

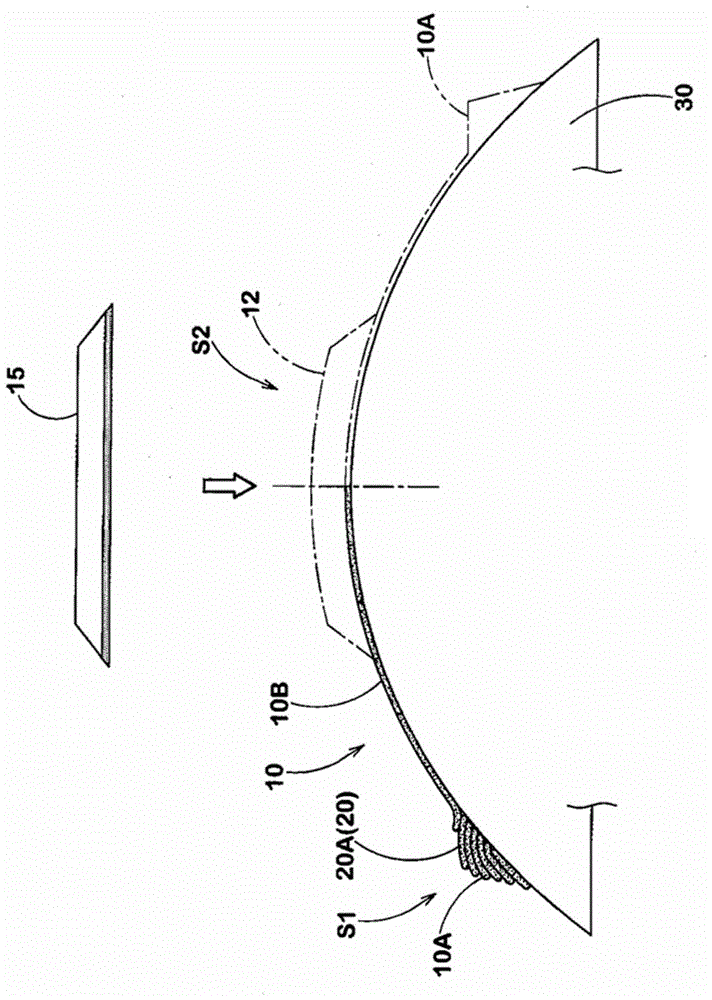

[0074] Among them, for each tread rubber, only the central top (surrounded by a thick line) is formed from extruded rubber integrally extruded by a rubber extruder, and the high temperature supplied from a gear pump type intermittent extruder is utilized. STW (sometimes referred to as high-temperature STW) of rubber strips in a low-temperature state to form the shoulder top by using STW (sometimes referred to as low-temperature STW) of rubber strips in a low-temperature state supplied from a continuous extruder via a reser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com