Double sides setting wire-feed rack

A wire feeding, bilateral technology, applied in the field of bilateral upper shaft wire feeding frame, can solve the problems of no tension adjustment mechanism, reduce production efficiency, disturb the order of wire payout, etc., and achieve the effect of convenient application, improved production efficiency, and convenient tension adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the examples and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

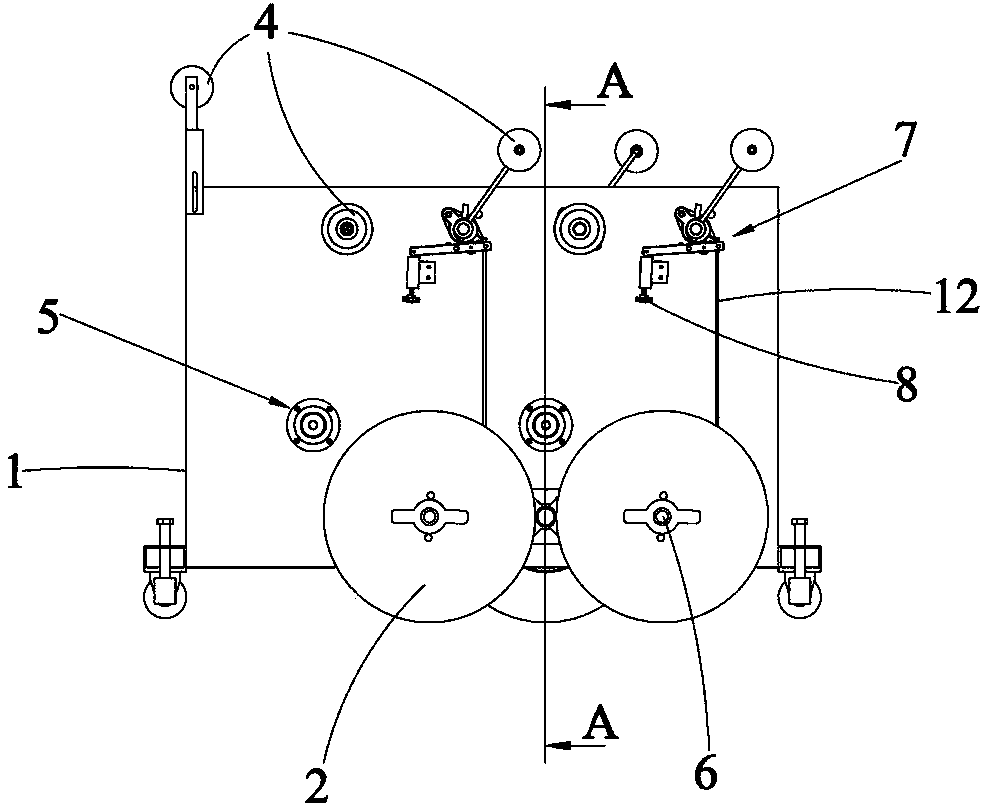

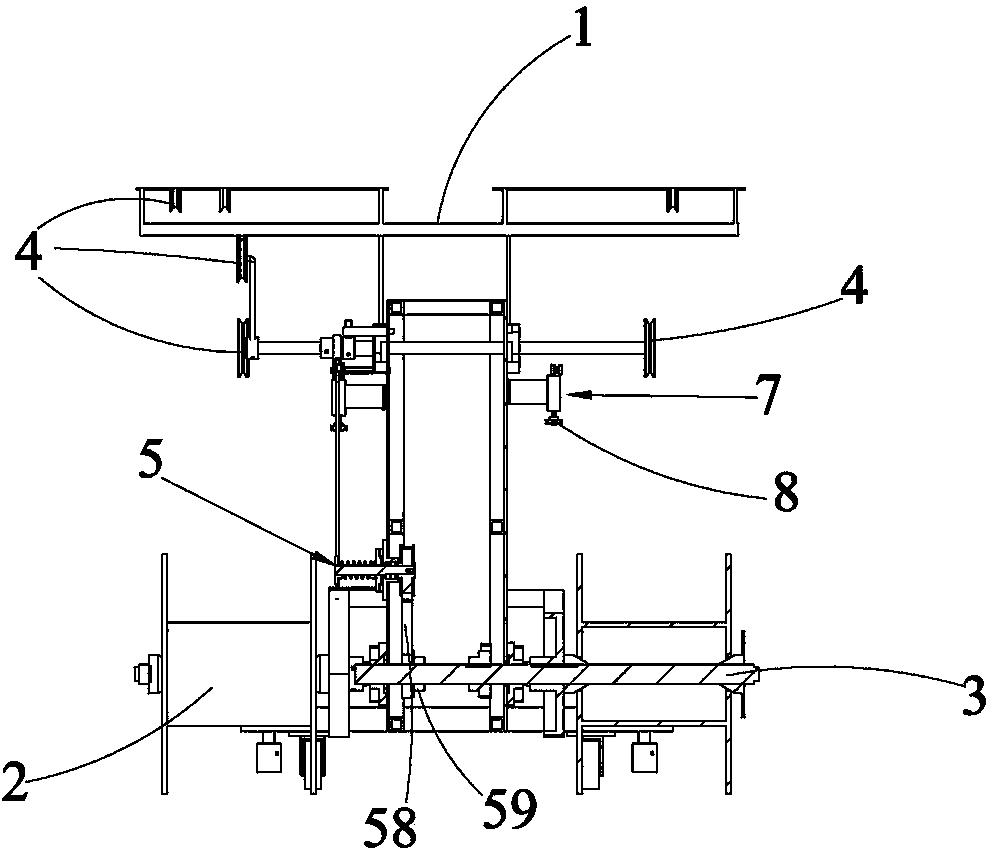

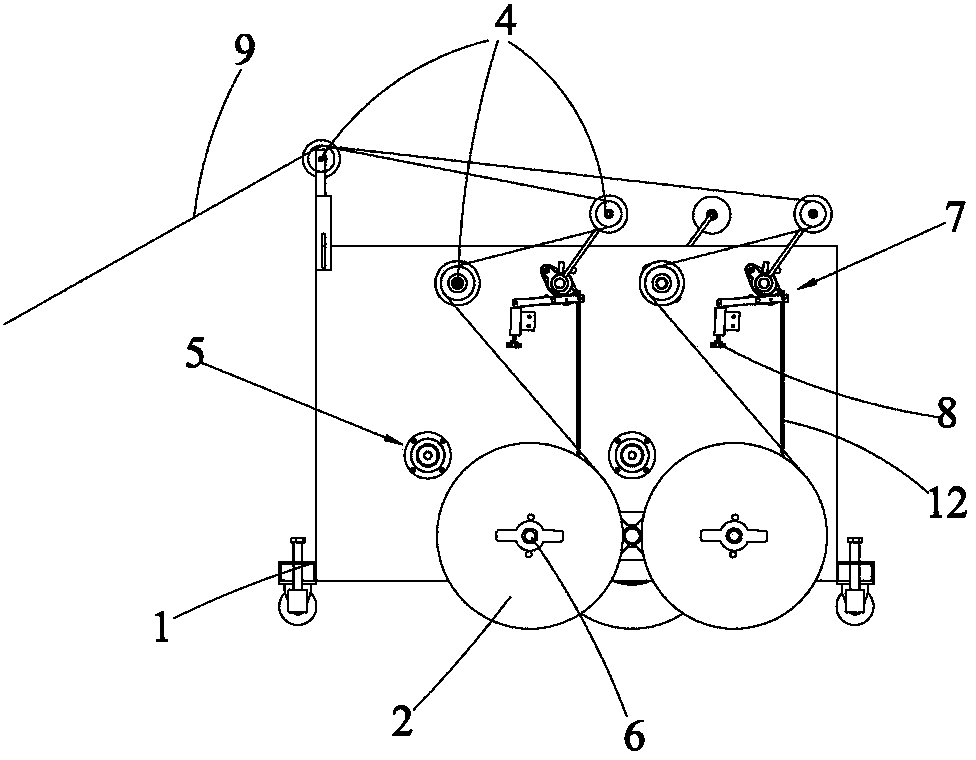

[0020] Such as Figures 1 to 6 As shown, the present invention provides a double-sided upper shaft wire feeding frame, including a frame 1, several pay-off shafts 2 arranged on the frame 1, a shaft center 3, several guide wheels 4 and several tension adjustment mechanisms 5. Both ends of the pay-off shaft 2 are fixed on the shaft center 3 through the plug 6, the shaft center 3 is connected with the tension adjustment mechanism 5, and the pay-off shaft 2 and the tension adjustment mechanism 5 correspond one by one, and several guide wheels 4 are set On rack 1. The top 6 positioned at the outside can be disassembled to facilitate the replacement, installation and maintenance of the pay-off shaft 2.

[0021] Among them, such as Figure 6 As shown, the tension adjustment mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com