An automatic control system for releasing foil in the production of electrode foil

An automatic control system and electrode foil technology, applied in general control systems, control/regulation systems, electrical program control, etc., can solve problems such as shortening the service life of equipment, hidden dangers, and inaccurate surface tension of foil surfaces, and achieve per capita work. The effect of improving efficiency, ensuring operational safety, and ensuring operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

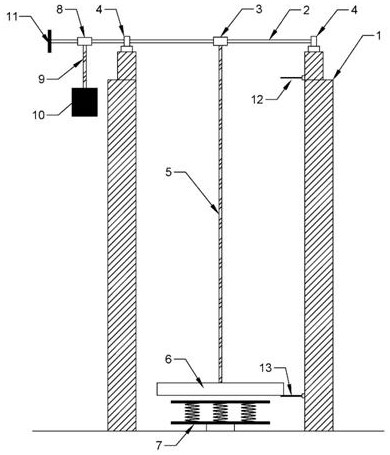

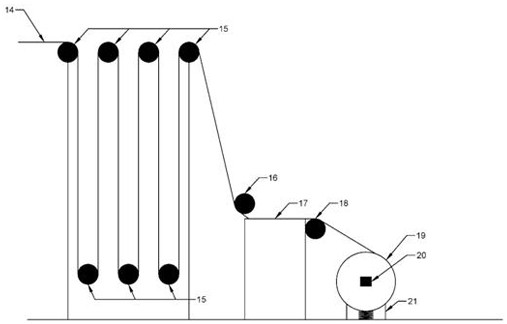

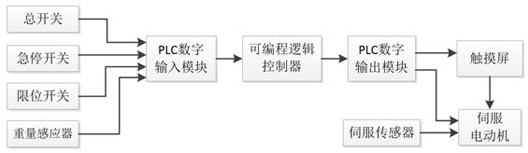

[0019] like figure 1 , figure 2 , image 3 , Figure 4 An embodiment of an automatic foil releasing control system in electrode foil production is shown, including a foil releasing device, a foil connecting device, a PLC control module, and a servo control module. The foil release device consists of a frame 1, a metal shaft 2, a delay rope reel 3, a bearing and a bearing seat 4, a foil release delay traction rope 5, a foil release delay transmission roller group 6, a spring protection bracket 7, and a Heavy rope reel 8, counterweight traction rope 9, counterweight 10, turntable 11, upper limit switch 12 and lower limit switch 13, the metal shaft 2 is used to connect delay rope reel 3, bearing and bearing seat 4. The counterweight rope reel 8 and the turntable 11, the bearing and the bearing seat 4, the upper limit switch 12 and the lower limit switch 13 are all installed on the frame 1, and the delay rope reel 3 and the foil release delay The transmission roller group 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com