Spinning frame spindle structure with damping effect

A spinning frame and spindle technology, which is applied in the field of spinning frame spindle structure, can solve problems such as increasing the burden, and achieve the effects of reducing downtime and replacement time, ensuring tension stability, and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

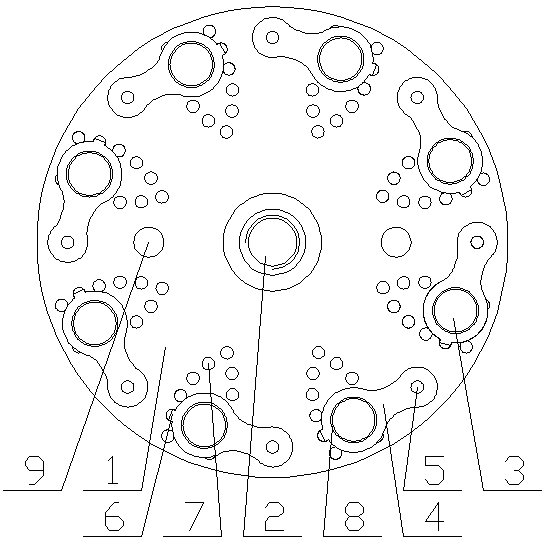

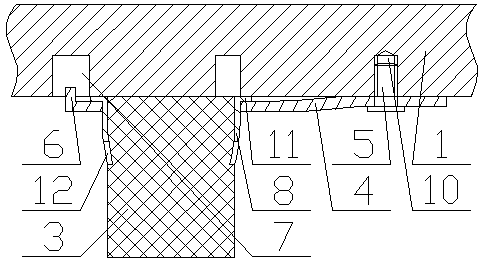

[0034] Combine figure 1 with figure 2 It can be seen that the present invention includes an ingot 1 with a through hole 2 for fixing the shaft at the center of the ingot 1, and 8 damping blocks 3 are evenly distributed on the edge of the bottom surface of the ingot 1, the damping blocks 3 is fixed to the ingot 1 by a spring sheet 4, the damping block 3 is fixed to one end of the spring sheet 4, the other end of the spring sheet 4 is rotatably connected to the ingot 1 through a pin 5, and the spring sheet 4 is located in the damping One end of the block 3 is provided with a hook 6 which is clamped in a positioning groove 7 provided on the bottom surface of the ingot 1, on the ingot 1, located in the circle surrounded by the through hole 2 and the damping block 3. There is also a pair of threaded through holes 9 therebetween, and the top surface of the spindle 1 is fixed with a positioning block matching the yarn reel through the threaded through holes 9; the distance between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com