Two-way stretching long-distance conveying device between longitudinal tensile machine and transverse tensile machine

A long-distance conveying, biaxial stretching technology, applied in the direction of flat products, household appliances, other household appliances, etc., can solve the problems of a large number of TDO waste films and firing pins, the influence of product thickness, and the influence of normal production, etc., to reduce sheet jitter , The effect of improving the quality of film products and ensuring the stability of export tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

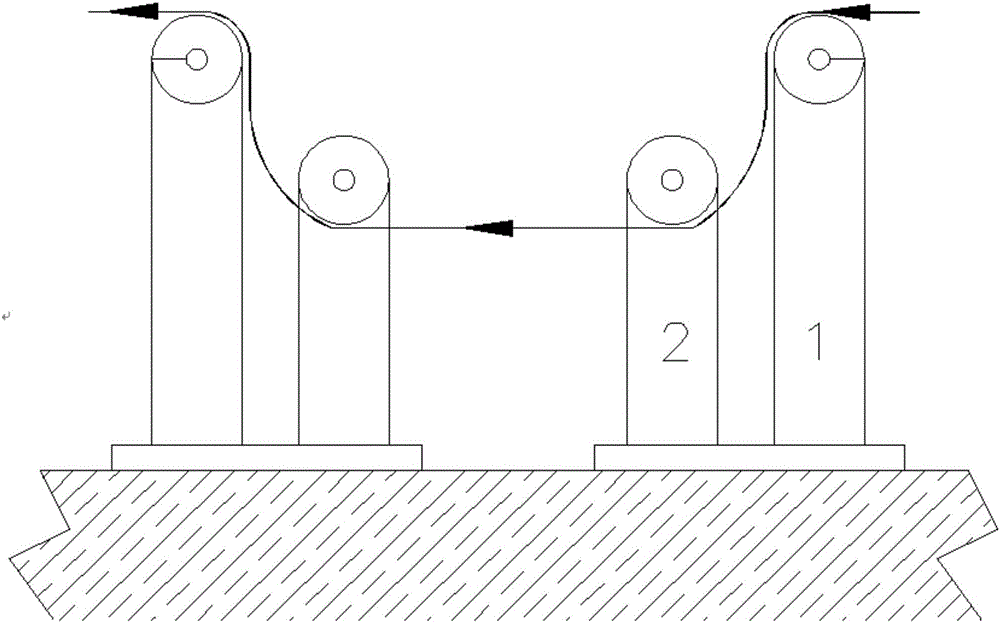

[0025] The long-distance conveying device between the longitudinal stretching machine and the horizontal stretching machine of bidirectional stretching, the double S guide rollers are set between the longitudinal stretching machine and the horizontal stretching machine with a distance of 3.1 meters, and the double S guide rollers are two symmetrical groups The S guide rollers are respectively arranged on the side of the longitudinal drawing machine and the side of the horizontal drawing machine; the S guide rollers include the upper guide roller and the lower guide roller whose surface material is all hardened aluminum, the surface roughness is 0.19um, and the shape is both cylindrical, and The upper guide roller is closer to the longitudinal drawing machine or the horizontal drawing machine. In terms of spatial position, the upper guide roller is higher than the lower guide roller. As shown in the attached figure, the horizontal center distance between the upper guide roller an...

Embodiment 2

[0028] The long-distance conveying device between the longitudinal stretching machine and the horizontal stretching machine of bidirectional stretching, the double S guide rollers are set between the longitudinal stretching machine and the transverse stretching machine with a distance of 3.3 meters, and the double S guide rollers are two symmetrical groups The S guide rollers are respectively arranged on the side of the longitudinal drawing machine and the side of the horizontal drawing machine; the S guide rollers include the upper guide roller and the lower guide roller whose surface material is all hardened aluminum, the surface roughness is 0.16um, and the shape is both cylindrical, and The upper guide roller is closer to the longitudinal drawing machine or the horizontal drawing machine. In terms of spatial position, the upper guide roller is higher than the lower guide roller. The horizontal center distance between the upper guide roller and the lower guide roller of the S...

Embodiment 3

[0031]The long-distance conveying device between the longitudinal stretching machine and the horizontal stretching machine of bidirectional stretching, the double S guide rollers are set between the longitudinal stretching machine and the transverse stretching machine with a distance of 3.5 meters, and the double S guide rollers are two symmetrical groups The S guide rollers are respectively arranged on the side of the longitudinal drawing machine and the side of the horizontal drawing machine; the S guide rollers include the upper guide roller and the lower guide roller whose surface material is hardened aluminum, the surface roughness is 0.18um, and the shape is both cylindrical, and The upper guide roller is closer to the longitudinal drawing machine or the horizontal drawing machine. In terms of spatial position, the upper guide roller is higher than the lower guide roller. The horizontal center distance between the upper guide roller and the lower guide roller of the S guid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com