Damping wharve structure for spinning frames

A spinning frame and spindle technology, which is applied in the field of spinning frame spindle structure, can solve problems such as increasing the burden, and achieve the effects of reducing downtime and replacement time, improving applicability and facilitating replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

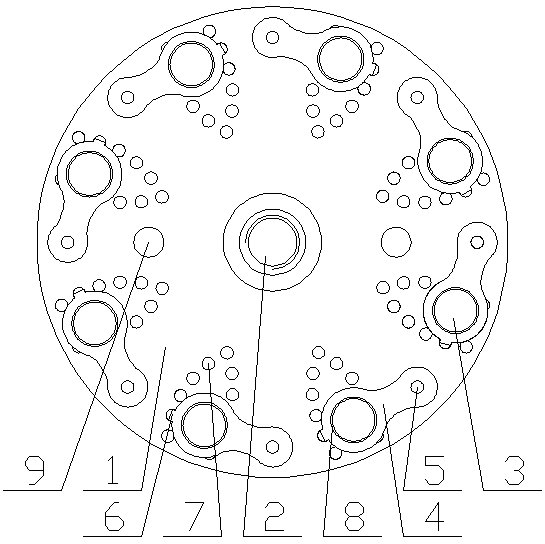

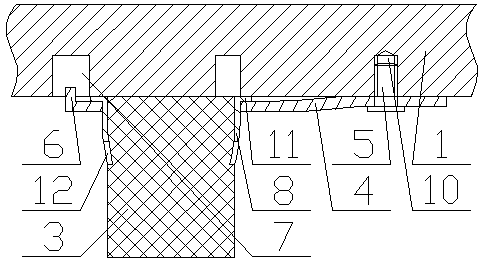

[0034] combine figure 1 and figure 2 It can be seen that the present invention includes a spindle disc 1, the center of which is provided with a through hole 2 for fixing the shaft, and eight damping blocks 3 are evenly distributed on the edge of the bottom surface of the spindle disc 1, and the damping blocks 3 is fixed to the spindle disk 1 by the spring piece 4, the damping block 3 is fixed on one end of the spring piece 4, and the other end of the spring piece 4 is connected to the spindle disk 1 through the pin shaft 5, and the spring piece 4 is located at the damping One end of the block 3 is provided with a hook 6, and the hook 6 is set in the positioning groove 7 provided on the bottom surface of the ingot disc 1. On the ingot disc 1, it is located in the circle formed by the through hole 2 and the damping block 3. A pair of threaded through holes 9 are also arranged between them, and the top surface of the spindle disc 1 is fixed with a positioning block matched wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com