Drilling gas extraction method of Y-shaped ventilation high-level return airway in gob-side entry

A technology for gas extraction and air return roadway, which is applied in the direction of gas discharge, earthwork drilling, mining equipment, etc. It can solve the problems of large roadway deformation, hole blocking, and easy cutting of drilling holes, etc., so as to facilitate construction management and avoid The effect of mutual interference and long-term efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

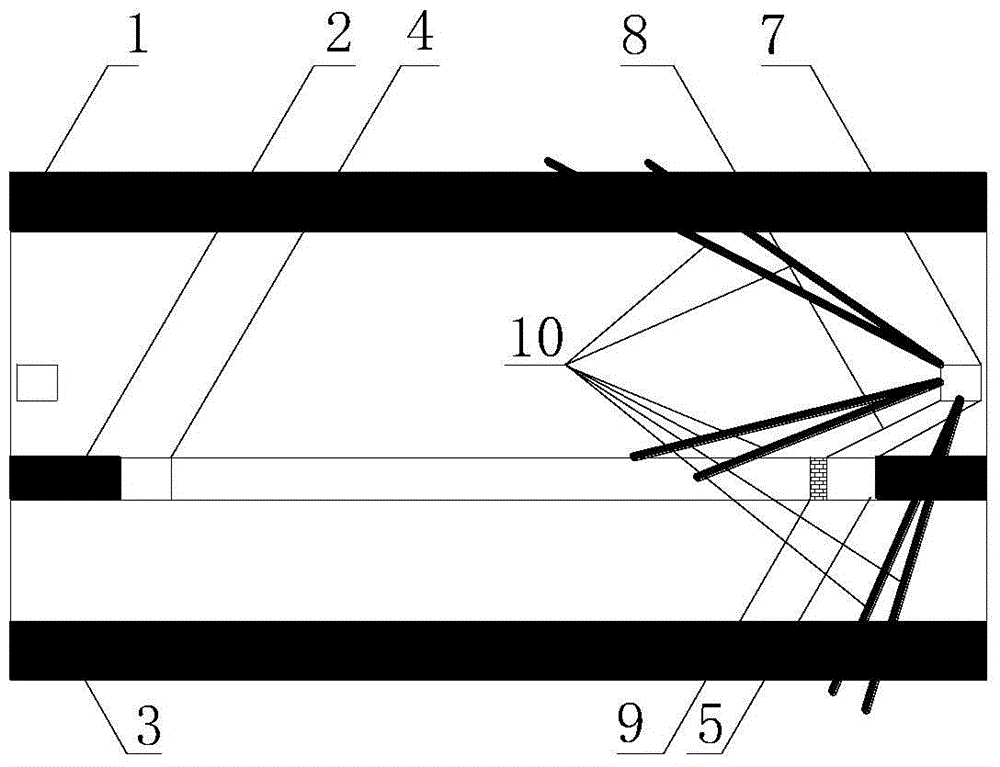

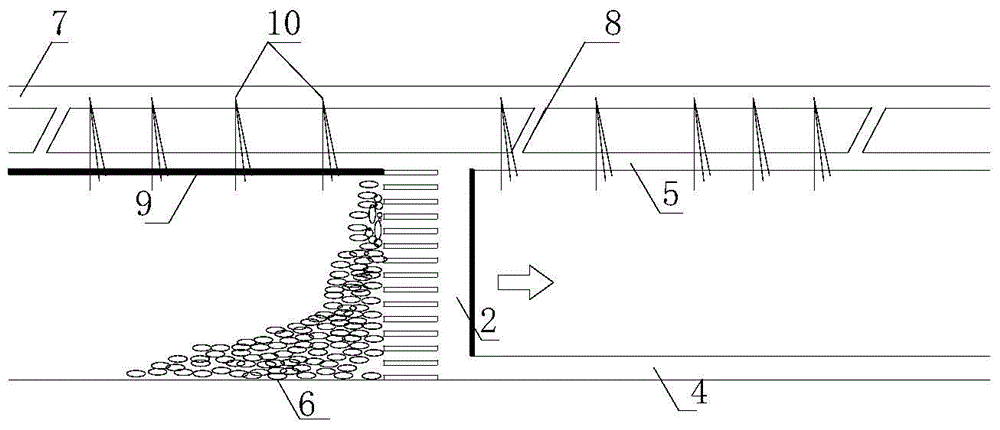

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0018] The specific steps of the gas extraction method of the Y-type ventilation high-level return airway drilling along the gob-side entryway of the present invention are as follows:

[0019] a. Construct a connecting lane 8 every certain distance between the top pumping lane 7 of the track level lane and the track level way 5, and the distance is 100-300m;

[0020] b. When the working face 2 of the protective layer is recovered, the filling wall 9 is built along the edge of the goaf 6, and the track level road 5 after the mining of the working face 2 of the protective layer is retained, and the working face 2 of the protective layer is covered by the transport level road 4 and track level lane 5 enter the air, and the air is returned from the reserved lane section of the track level lane, the connecting lane 8 and the top extraction lane 7 of the track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com