Furnace body high-temperature-state rotating sealing structure

A technology of rotating sealing structure and high-temperature state, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as unsuitability for use, wear and tear, and achieve improved performance, simple and reliable structural design, and adjustable sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

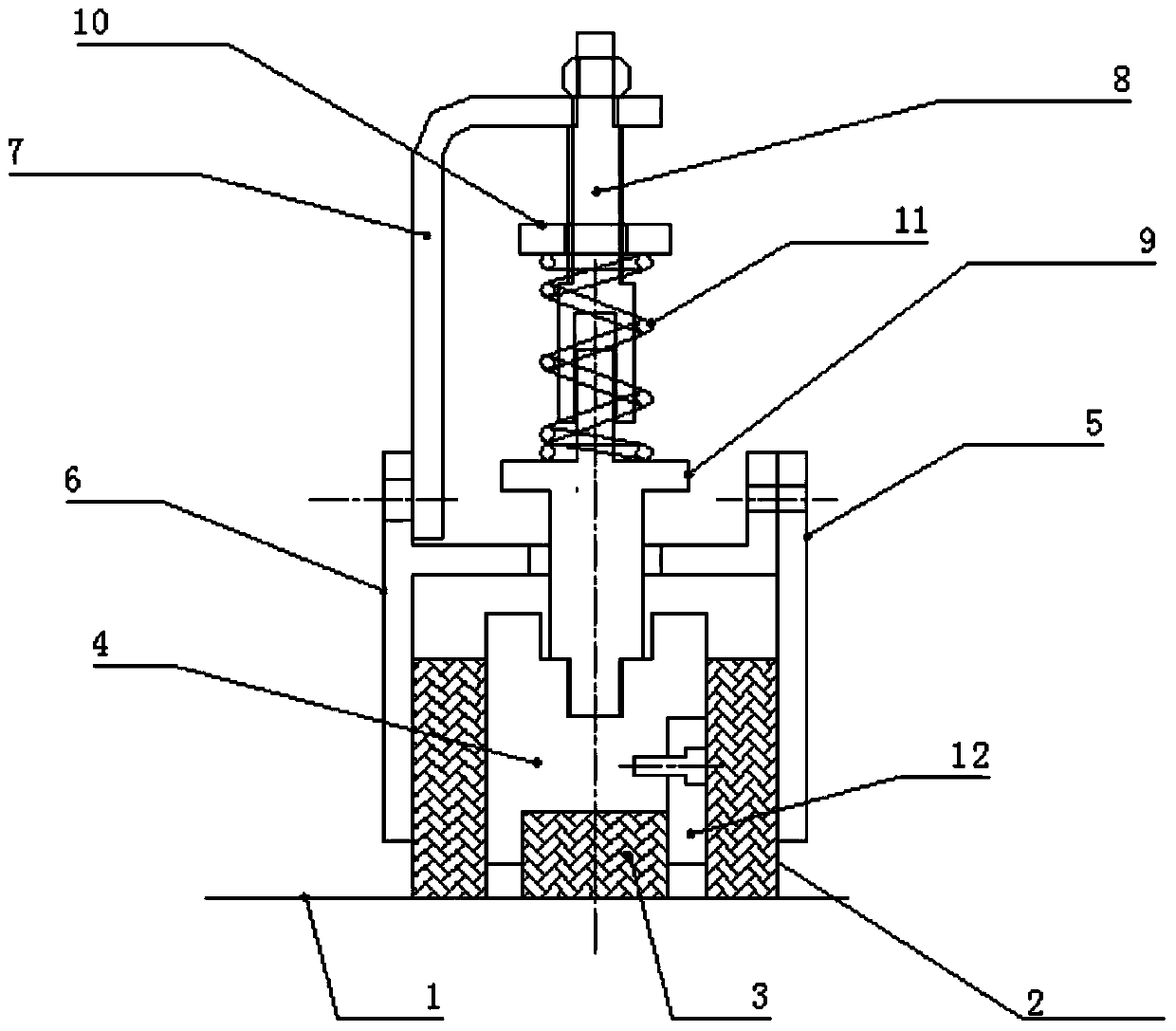

[0010] Referring to the accompanying drawings, the furnace body has a rotating and sealing structure at high temperature. On the contact surface 1 of the furnace body, there are two hard packing 2 and flexible packing 3. A pressure ring 4 is engaged on the flexible packing 3. Both sides of the pressure ring 4 are connected to the The hard packing 2 is slidingly fitted, and the two hard packing 2 are respectively pressed with a sealing cover retaining ring 5 and a sealing cover 6. The sealing cover 6 is fixedly connected with an L-shaped support plate 7, and the upper end of the support plate 7 is fixedly connected with a The upper guide rod 8, the upper guide rod 8 is slidingly matched with the lower guide rod 9, the lower end of the lower guide rod 9 passes through the sealing cover 6, the lower end of the lower guide rod is pressed on the pressure ring 4, and the upper guide rod 8 is screwed with an adjusting nut 10. The lower guide rod has a step, a spring 11 is pressed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com