A method for connecting prefabricated reinforced concrete slabs

A technology of reinforced concrete slabs and connection methods, which is applied in construction, building structure, etc., can solve the problems of complex construction process and affect the mechanical performance, etc., and achieve the effect of improving bonding performance, improving performance, and facilitating transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The connection method of the prefabricated reinforced concrete slab of the present invention will be described in detail below with reference to the drawings and embodiments.

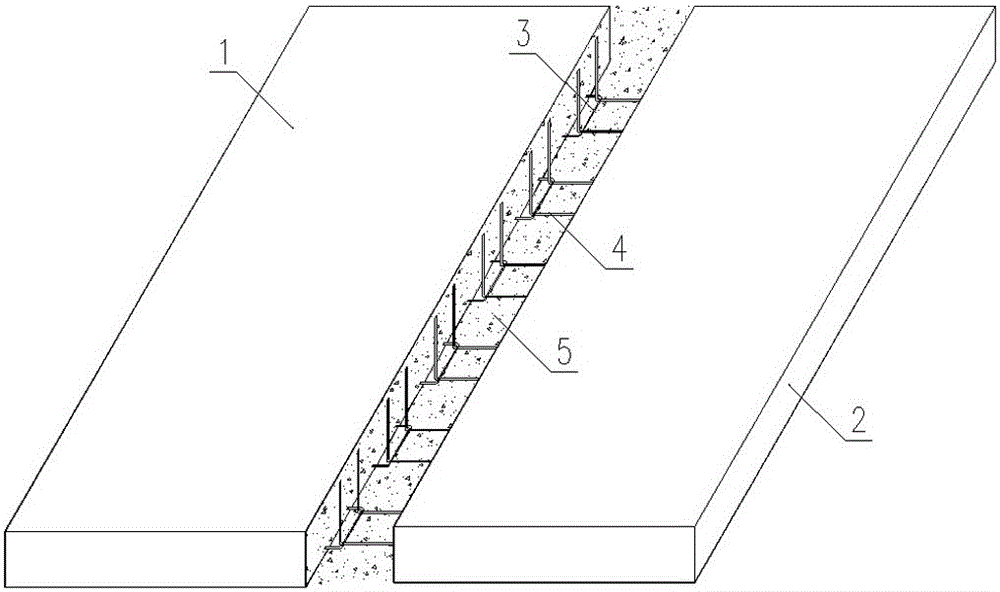

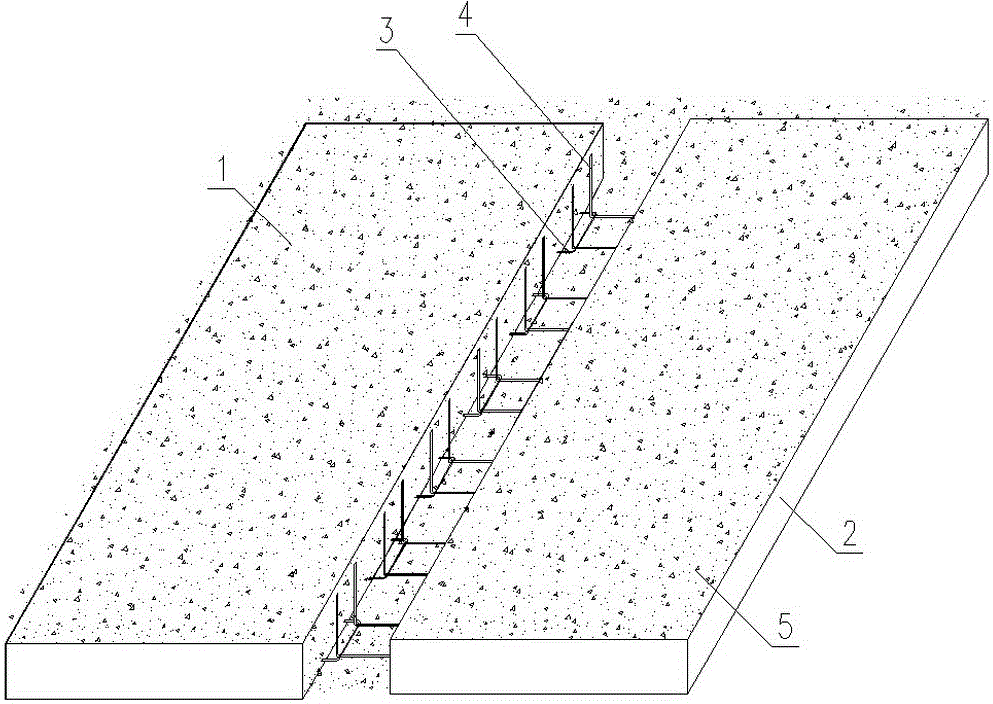

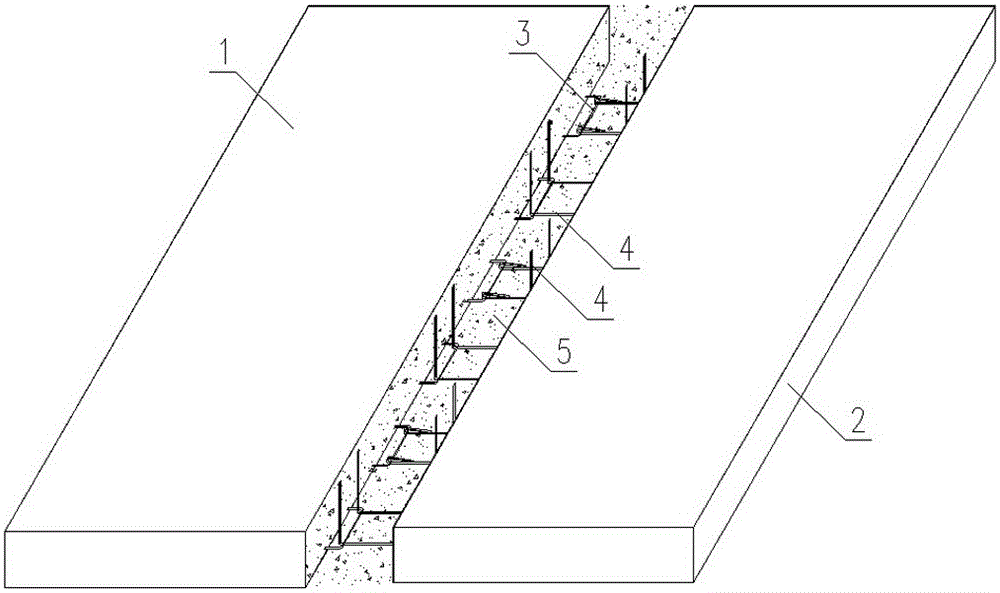

[0031] A kind of embodiment of the connection method of the prefabricated reinforced concrete slab that the present invention proposes, as figure 1 , the side of the first prefabricated reinforced concrete slab 1 is pre-embedded with fully anchored and semi-circular steel bars 3 with exposed parts; the side of the second prefabricated reinforced concrete slab 2 is pre-embedded with fully anchored and semi-circular steel bars with exposed parts, The semi-annular steel bar is hung with a horizontal steel bar 4 whose end is bent upward. The horizontal steel bar can move and rotate on the semi-annular steel bar, and the position can be adjusted freely, which is convenient for the transportation and hoisting of the prefabricated reinforced concrete slab, and facilitates the positioning of the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com