Double-driving non-contact transmission vertical oil sucking machine

A non-contact pumping unit technology, applied to transmission parts, mechanical equipment, mining fluids, etc., can solve the problems of high failure rate of reducer, affecting oil production time rate, and difficult maintenance, etc., and achieve the simplification and optimization of mechanical mining equipment , Solve the effect of high failure rate and eliminate the disadvantages of oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

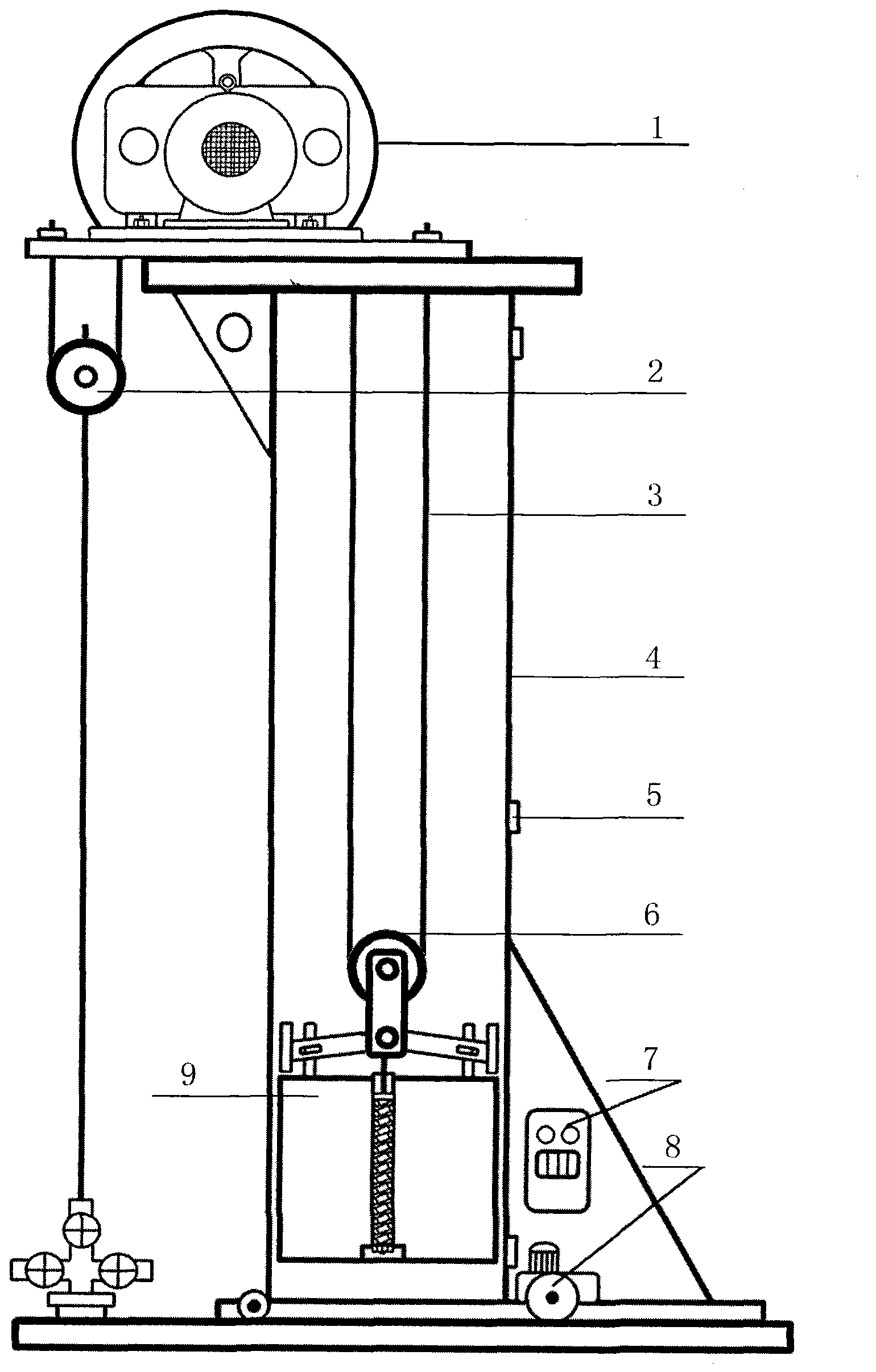

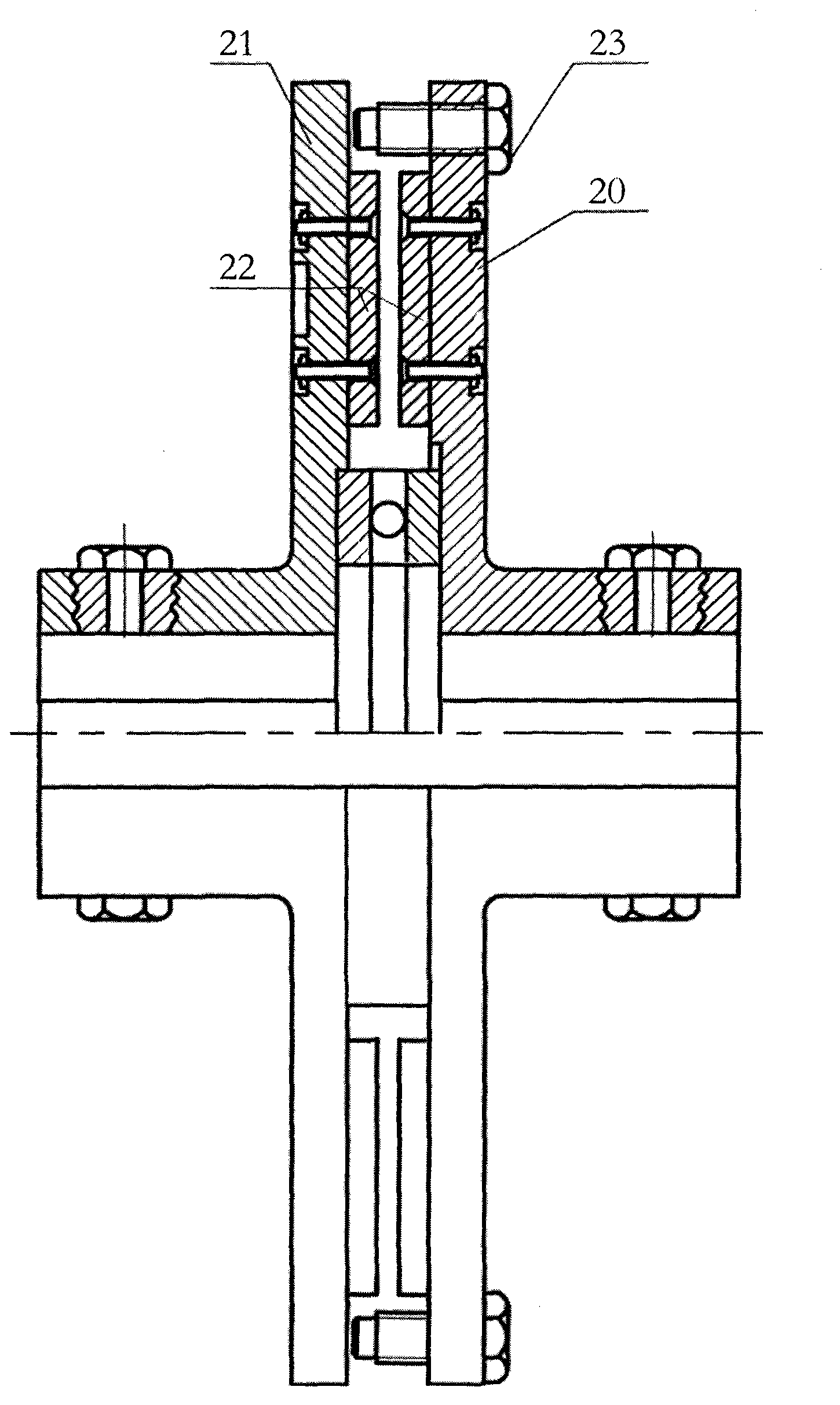

[0027] Such as figure 1 Shown: the double-drive non-contact transmission vertical pumping unit of the present invention comprises the double-drive four-safety reducer (1) placed on the top platform of the frame (4) and the electric moving machine device ( 8) and the digital intelligent controller (7) connected to the sensor (5) inside and outside the control cabinet at the lower part of the frame (4), wherein the double-drive four-safety reducer (1) drives the wheel (10) and puts one end in the rope groove through the front pulley (2) Suspension oil well load, the other end hangs the driving rope (3) of anti-fall balance weight (9) through rear movable pulley (6), and the other end is fixed in the protection rope groove and connects the protection rope of anti-fall balance weight (9).

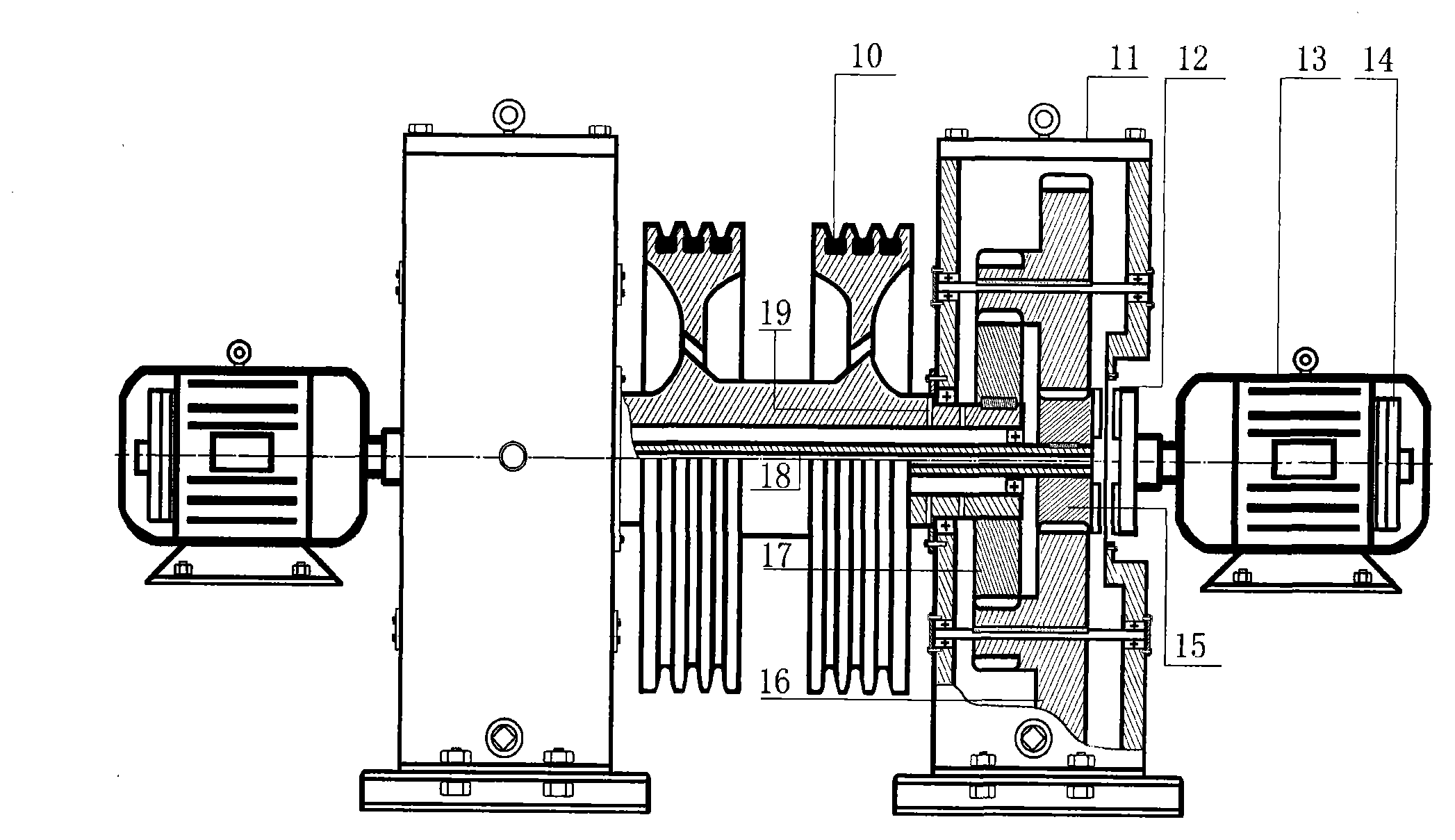

[0028] The double-drive four-safety speed reducer (1) includes 2 symmetrically connected in series with the same driving wheel (10) type hollow output shaft and the same input shaft (18) place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com