Optical fibre distribution frame and wiring method in optical fibre distribution frame

A technology of an optical fiber distribution frame and a wiring method, which is applied in the field of optical fiber communication, can solve the problems of an increase in the number of optical fibers and jumpers of optical cables, inconvenient operation, and complicated wiring and fiber routing, so as to solve the problem of wiring management and facilitate maintenance. And the effect of managing and enriching application functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

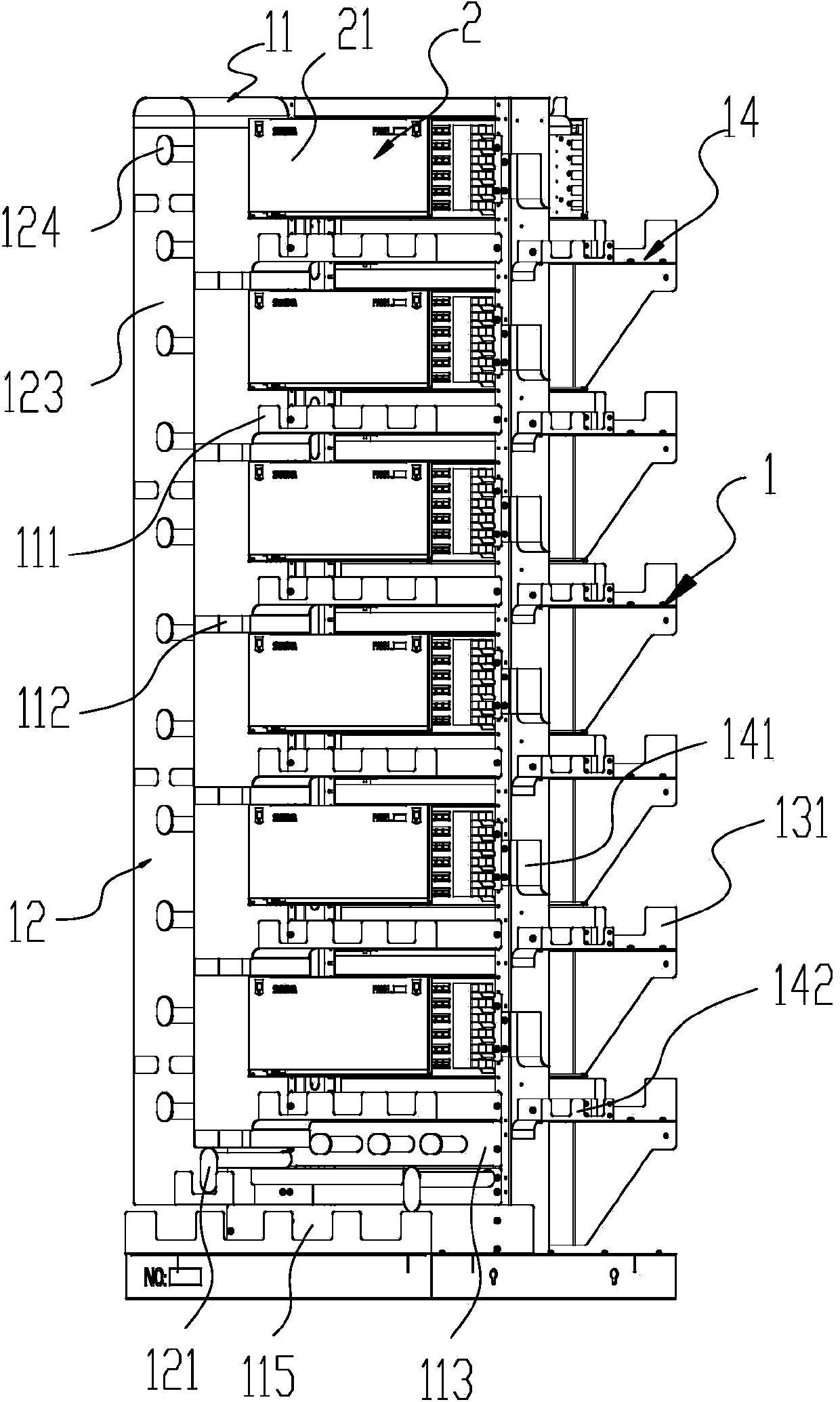

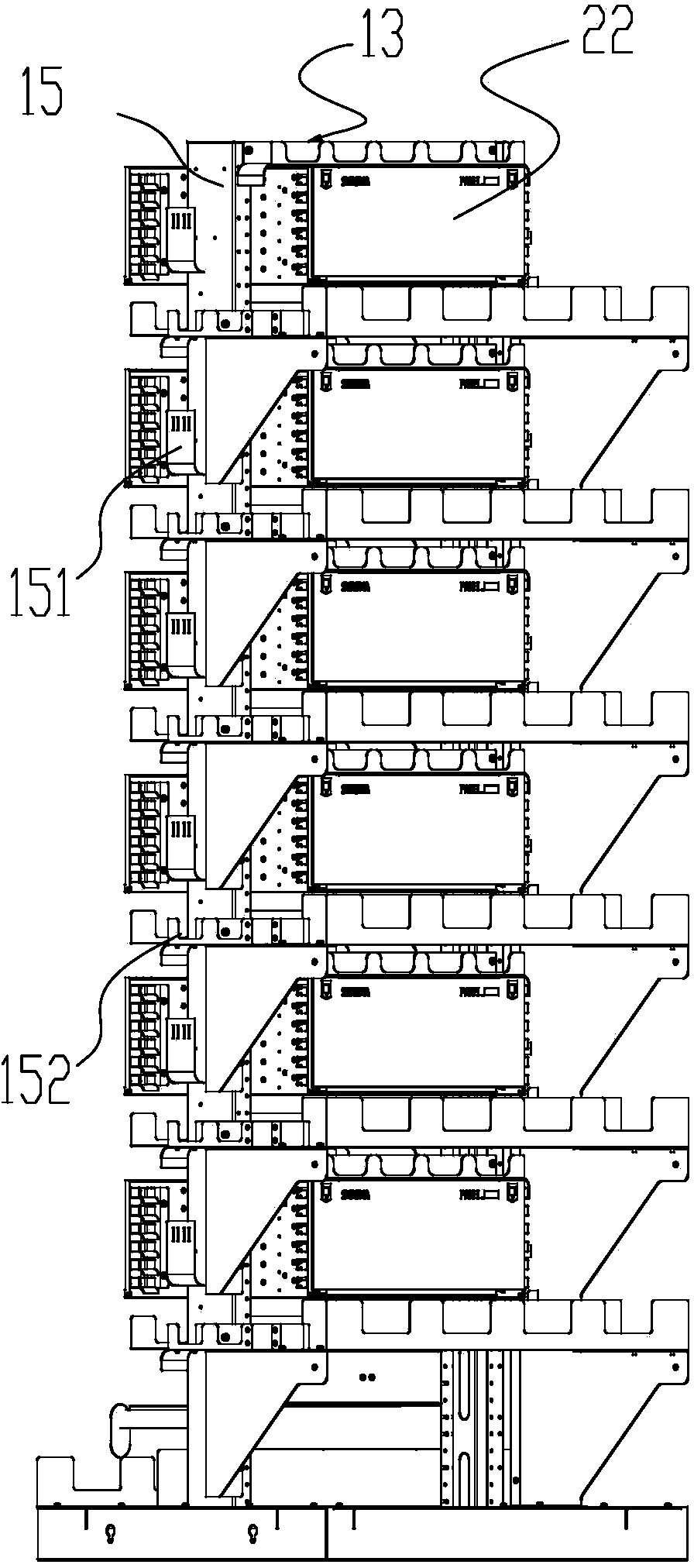

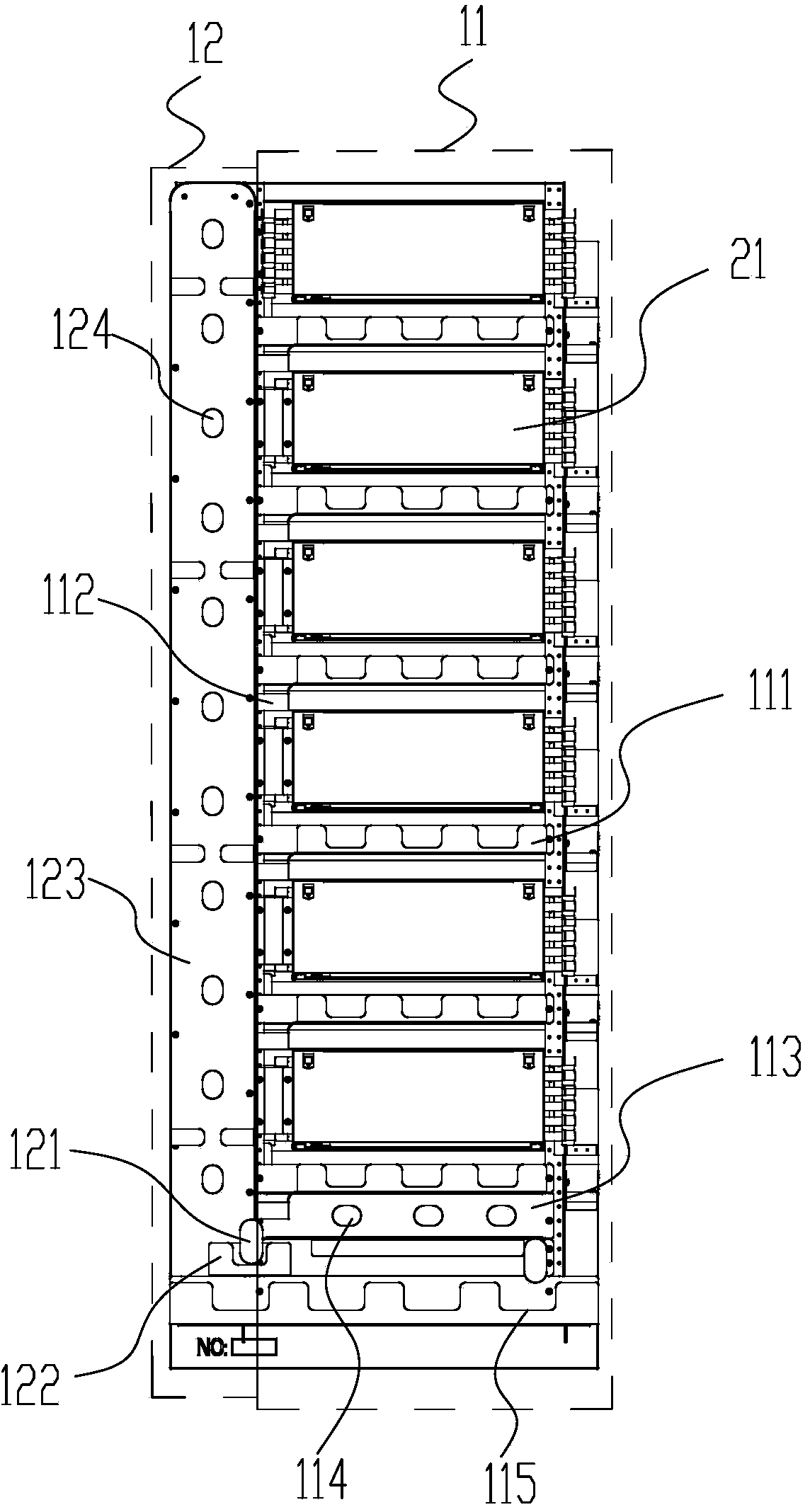

[0044]The optical fiber distribution frame in the prior art generally adopts single-sided operation, simple function, and small capacity, and the inter-rack fiber is routed through the fiber routing frame on the top of the machine room, which takes up a large space and high cost; in addition, the optical fiber distribution frame The internal fiber jumper wiring is complex and has many crossovers, which is not conducive to maintenance and management. In order to solve the above-mentioned defects existing in the prior art, the main innovation of the present invention is: by separately separating the end surface of the optical cable from the fiber jumper operation surface, the rack can be operated on both sides to realize functional partitioning, so that the rack The management is clearer; racks are equipped with dedicated horizontal channels and front and rear fiber routing channels for fiber jumping between racks, so that fiber jumping between racks does not need to be routed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com