Traction control device of sun-chasing type solar power generating mechanism

A traction control device, solar technology, applied in non-electric variable control, position/direction control, control/regulation system, etc., can solve problems such as high cost, reduced accuracy of power generation module rotation control, and impact on power generation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

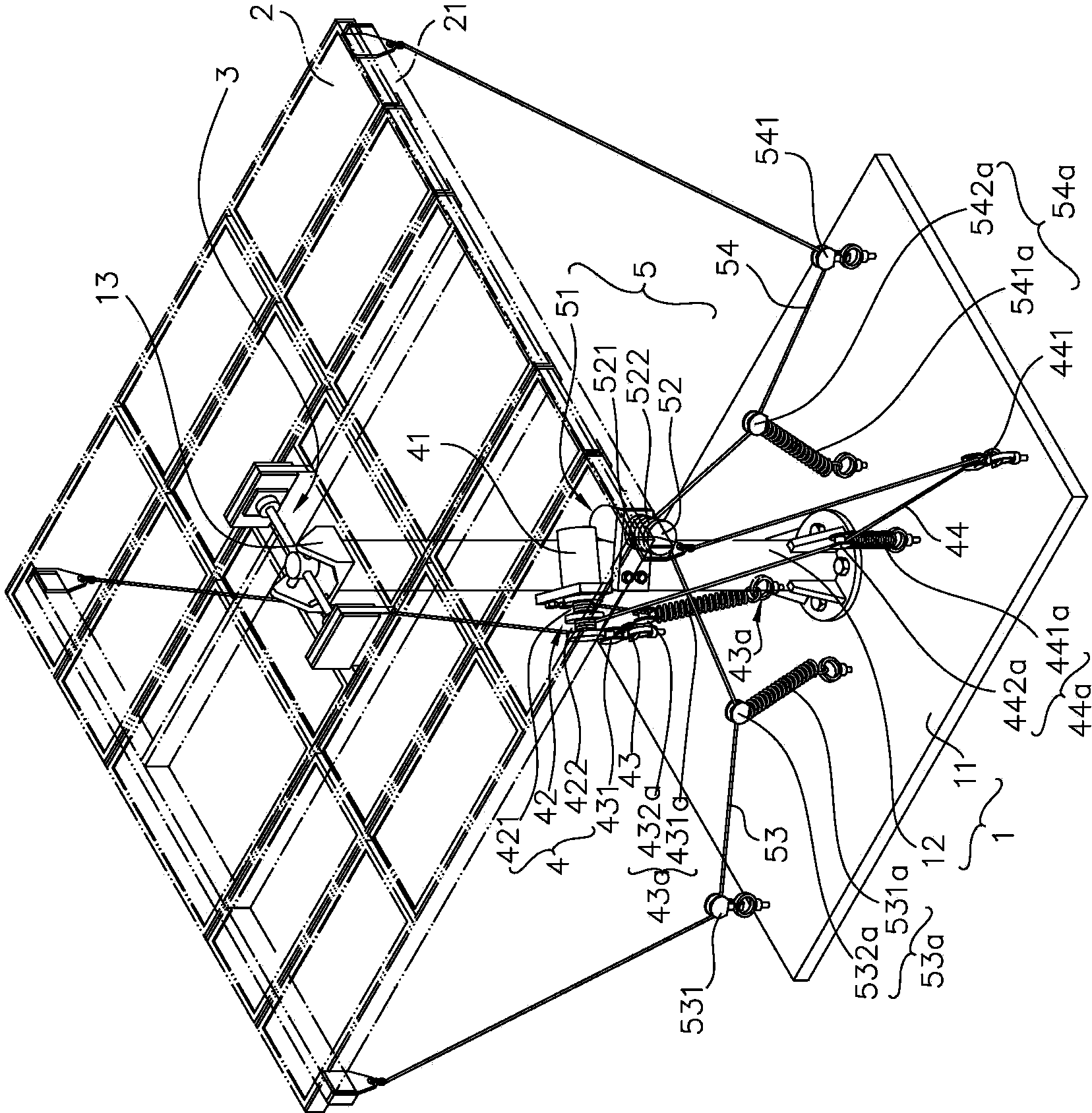

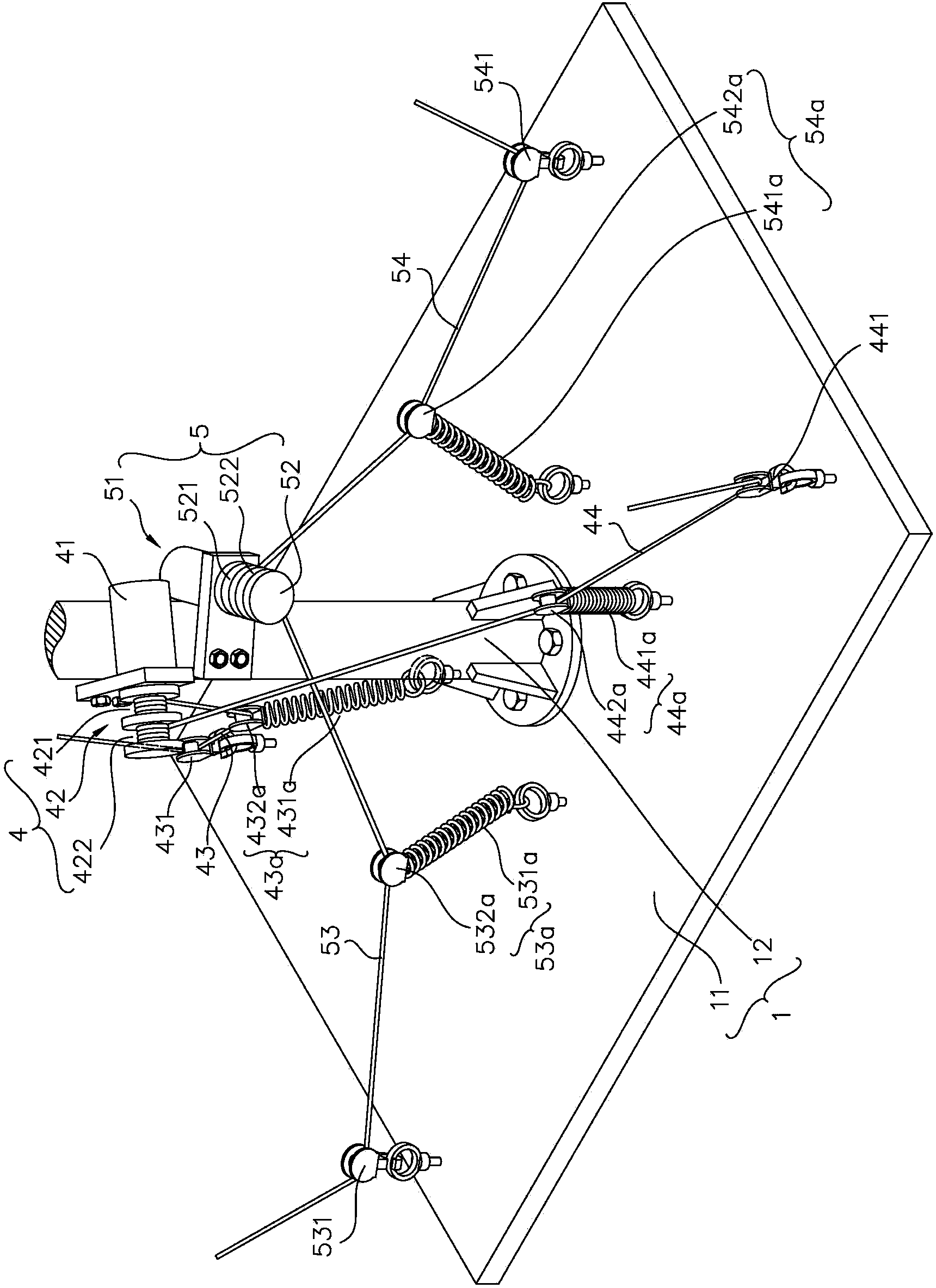

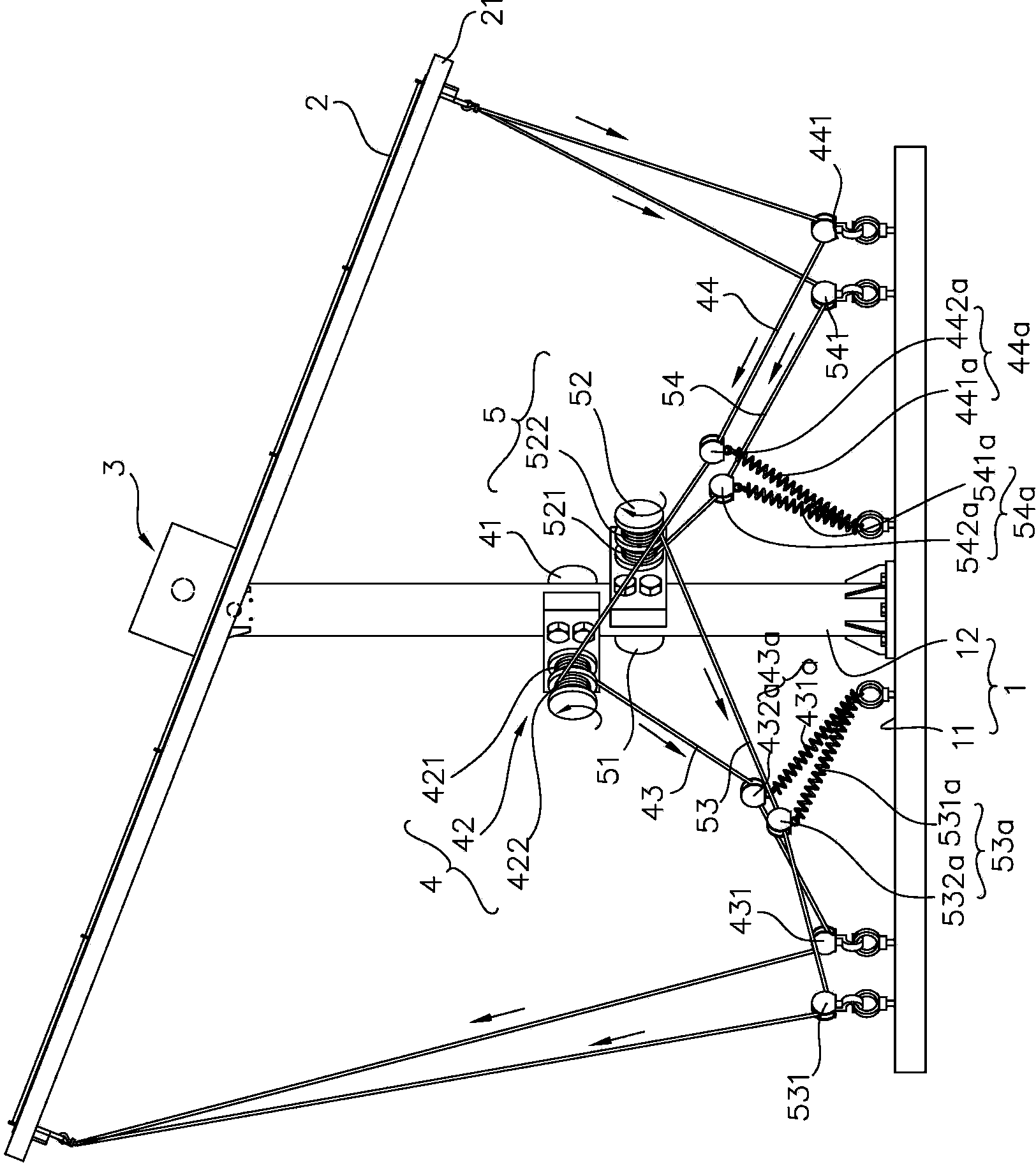

[0037] See Figure 1 to Figure 3 As shown, it can be seen that the structure of the first embodiment of the present invention mainly includes: the solar power generation module 2, and the linkage component group composed of the first linkage component 4 and the second linkage component 5, etc., wherein the solar power generation The module 2 is set on a support assembly 1 via a carrying platform 21, and the support assembly 1 is supported by a base 11, a pillar 12 arranged on the base 11, and a support 13 arranged on the pillar 12. Composed, and the carrying platform 21 is disposed on the support 13 through a pivot assembly 3 so that it can pivot two-dimensionally.

[0038] The first linkage assembly 4 may be, but not limited to, consist of a first power source 41, a first drive assembly 42 driven by the first power source 41, and two connecting cables 43, 44. The component 42 is provided with two synchronous first and second drive parts 421, 422. In the illustrated embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com