Smart glass cleaner and control method thereof

A technology of smart glass and control method, applied in cleaning equipment, window cleaning, household appliances, etc., can solve the problems of poor urban environment, inconvenient use, danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

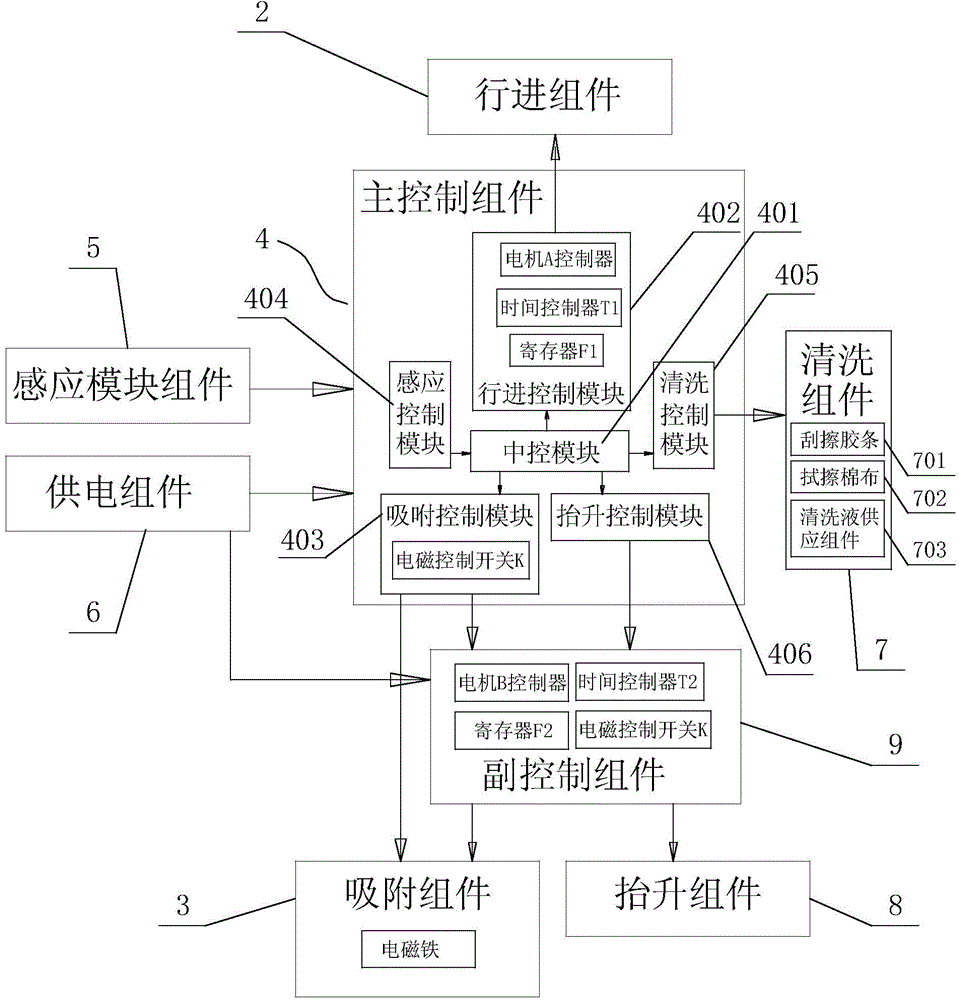

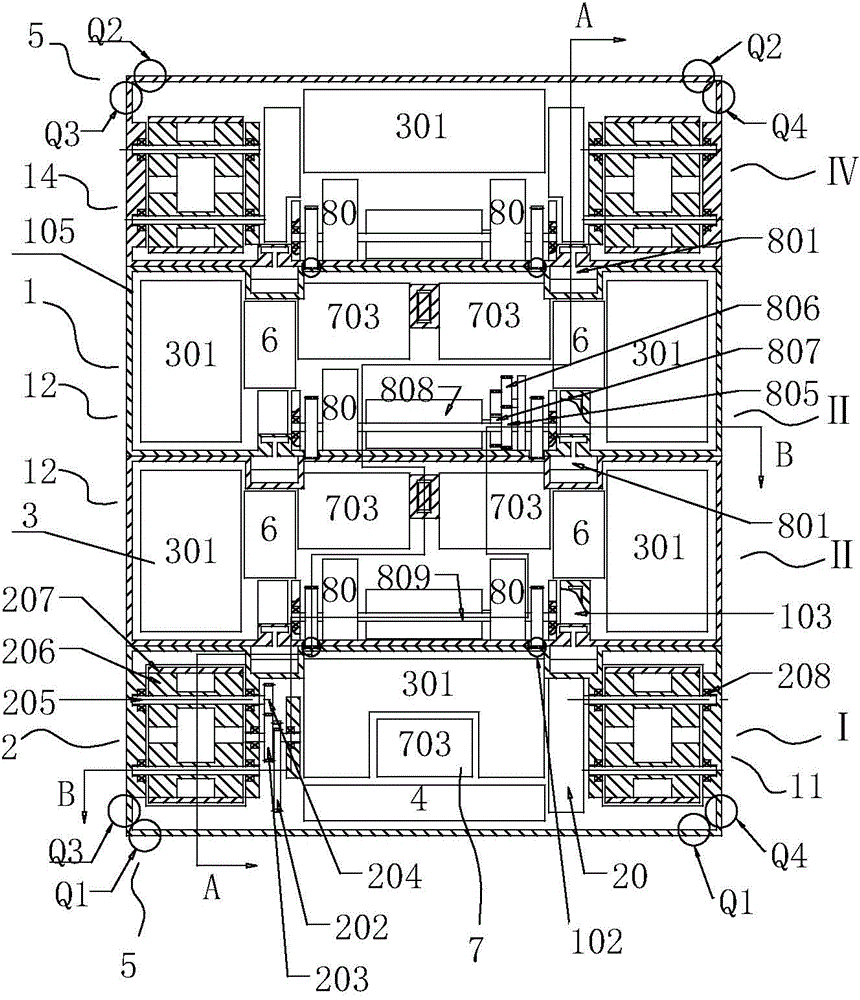

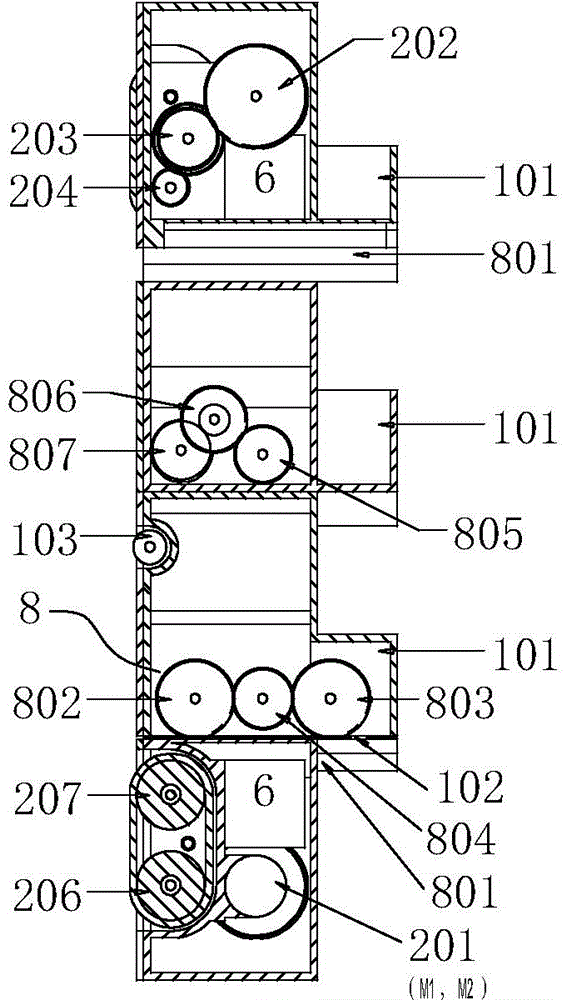

[0093] Figure 1-Figure 4 Disclosed in is an intelligent glass cleaner, including a housing assembly 1, a traveling assembly 2 installed in the housing assembly 1, an adsorption assembly 3, a main control assembly 4, an induction module assembly 5, a power supply assembly 6, a cleaning assembly 7, a lifting Component 8, sub-control component 9;

[0094] The traveling assembly 2 is used to realize the reciprocating process of the whole mechanism moving forward and backward under the control of the main control assembly 4;

[0095] The adsorption component 3 is used to achieve adsorption on both sides of the glass through magnetic attraction under the control of the main control component 4 or the secondary control component 9;

[0096] The sensing module component 5 is used to realize the signal collection of the whole mechanism to the outside world, and transmit the collected signal to the main control component 4;

[0097] The power supply assembly 6 is used to provide powe...

Embodiment 2

[0116] A control method for an intelligent glass cleaner, the method comprising the following steps:

[0117] S1. The electromagnet is energized;

[0118] S2. The register F1 of the travel control module of the main control assembly starts to collect and store location information and latch it;

[0119] S3. Detect whether it reaches the boundary, if yes, then directly enter step S5, if not, then enter step S4;

[0120] S4. advance, wipe the glass, repeat step S3;

[0121] S5. Judging whether to meet the jumping, if yes, then enter step S6, if not, then repeat step S3;

[0122] S6. Adjust the overturning position;

[0123] S7. Realize overturning, repeat step S2 until the cleaning work is finished.

[0124] The travel control steps in the above-mentioned step S4 are as follows:

[0125] S41. The whole machine is started, when the touch sensors Q2 and Q3 are touched at the same time, the left motor A M1 and the right motor A M2 rotate forward at a constant speed, and the wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com