A special horizontal correction gauge for small compressors

A technology of level correction and compressor, applied in the field of spirit level, can solve problems such as troublesome measurement and affecting production efficiency, and achieve the effect of improving production efficiency, convenient and quick operation, and solving the bottleneck process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

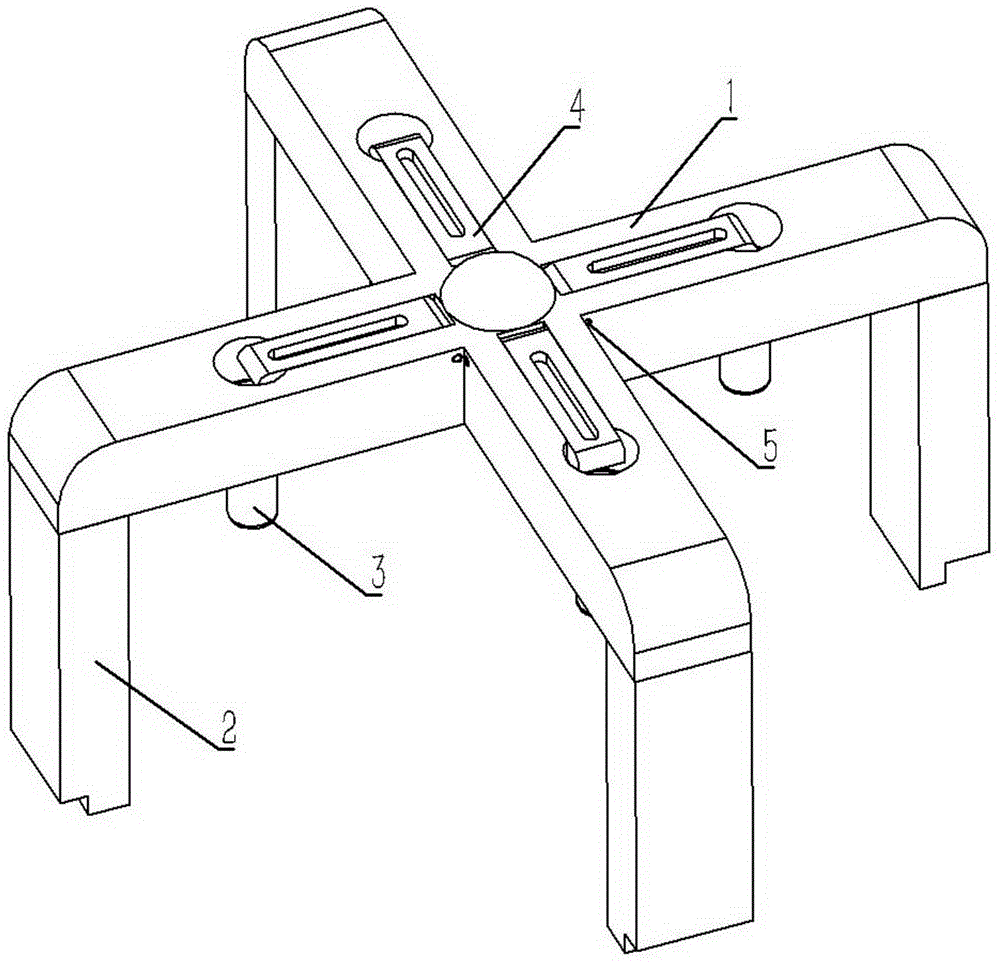

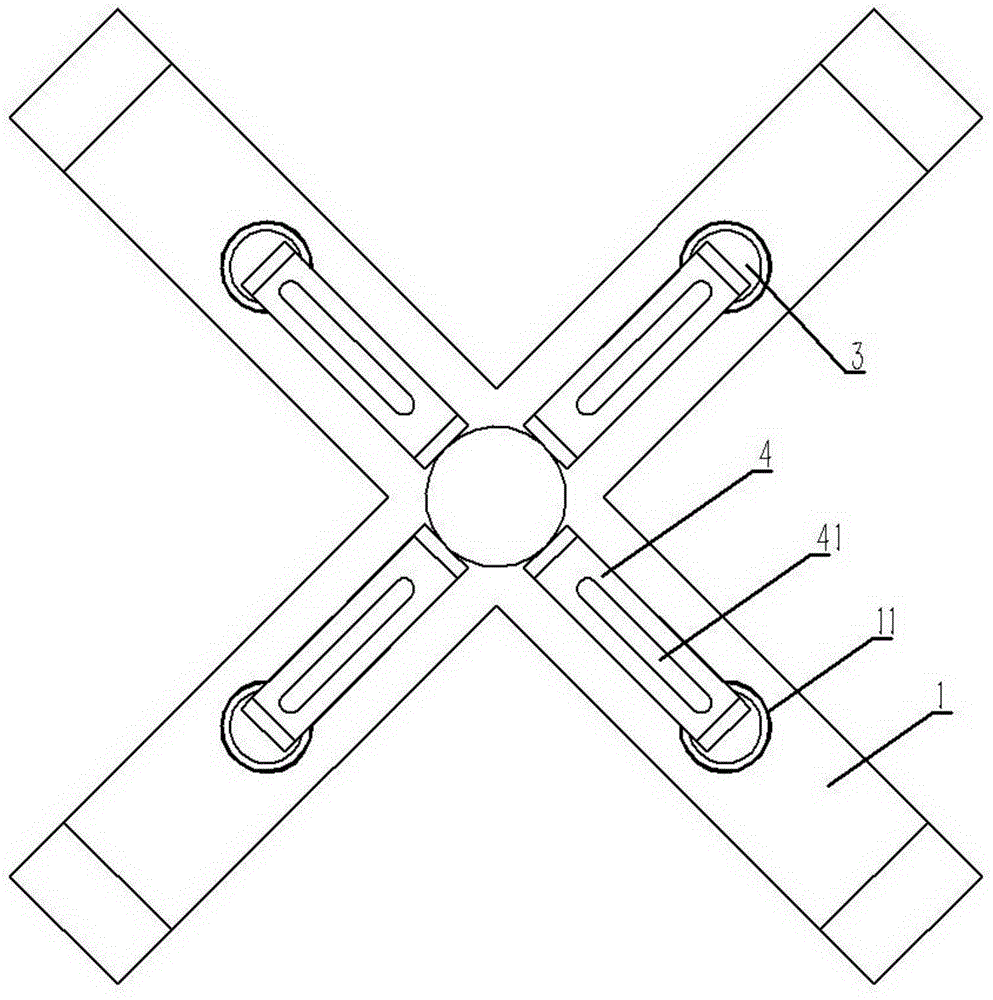

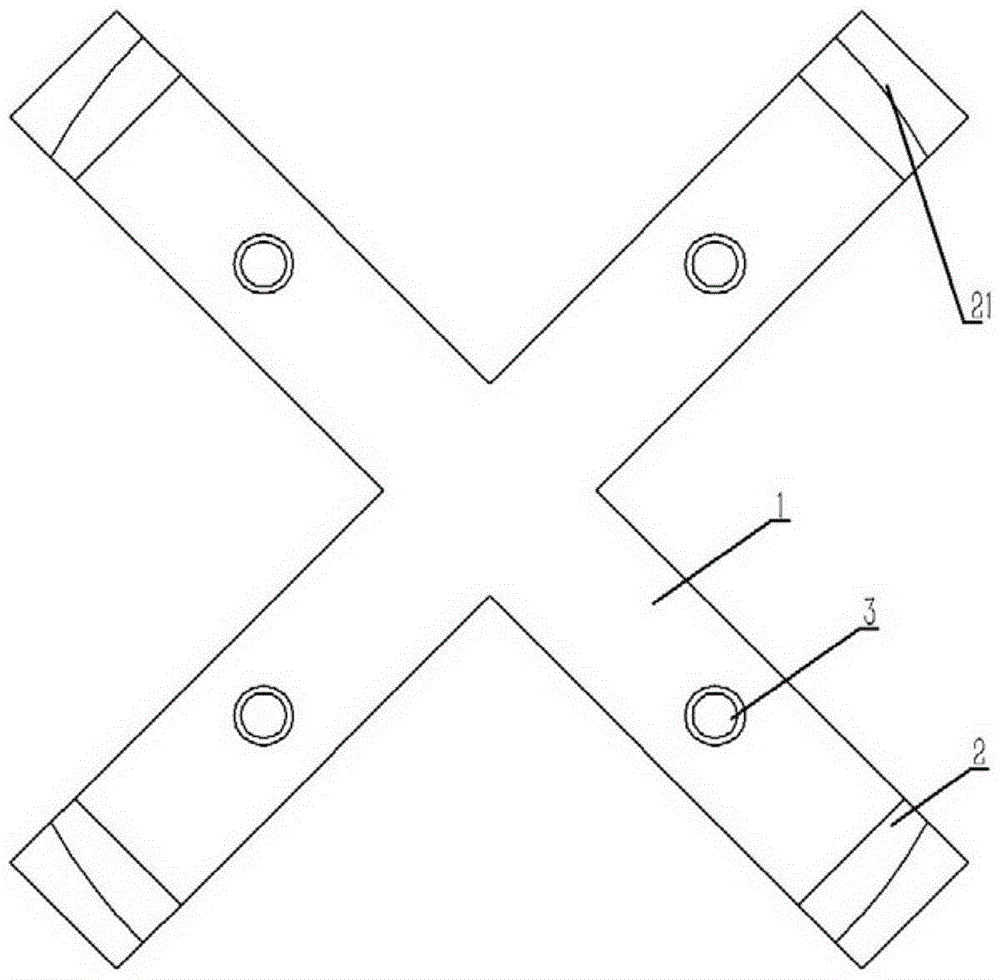

[0017] Example: see Figure 1 to 4 As shown, a level correction gauge dedicated to a small compressor includes an X-shaped main bracket 1. The four ends of the main bracket 1 are fixed with feet 2 respectively. The main bracket 1 is formed with a plurality of step holes 11, and step holes 11 A T-shaped measuring rod 3 is inserted into the sleeve. A level rod 4 is arranged above the measuring rod 3, and one end of the level rod 4 is hinged to the main support 1 through a pin 5.

[0018] The lower end of the leg 2 is formed with a cut groove 21, and the side surface of the leg 2 along the vertical cutting direction where the cut groove 21 is located is an arc surface.

[0019] A water tank 41 is formed on the level rod 4, and water is placed in the water tank 41 and covered to form a steam drum, which becomes a steam drum level gauge.

[0020] The upper end surface of the level rod 4 is parallel to the upper end surface of the main support 1.

[0021] The step hole 11 is composed of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com