Pressure cooker with functions of preventing splashing and collecting oil and water

A pressure cooker and anti-splash technology, which is applied in the field of pressure cookers, can solve the problems of increasing the exhaust pressure of pressure cookers, which is not conducive to the safe use of pressure cookers, and is not easy to be popularized and applied due to safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

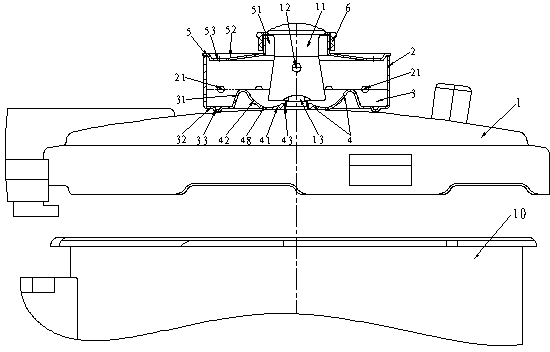

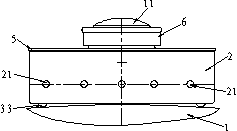

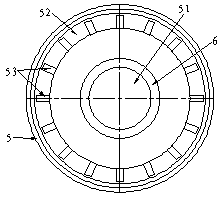

[0031] The pressure cooker with the function of preventing splash and collecting oil and water according to Embodiment 1 of the present invention (for the structure see Figure 1 to Figure 4), including a pot body 10 of a pressure cooker and a matching pot cover 1 with a pressure limiting valve, the pot cover 1 has a cylinder around the pressure limiting valve to block the mixed fluid sprayed from the pressure limiting valve The cover 2 is characterized in that: the lower part of the cylinder cover 2 is provided with a receiving groove 3 on the pot cover 1 around the pressure limiting valve bonnet 11; the receiving groove 3 consists of the side wall of the cylinder cover 2 and the inner circumference The inner ring wall 31 and the groove bottom 32 integrally connected between the bottom ends of the two constitute three components; there is an appropriate distance between the cylinder cover 2 and the bonnet 11, and its inner side is provided with a bonnet located below the bonne...

Embodiment 2

[0047] The pressure cooker with the function of preventing splash and collecting oil and water according to the second embodiment of the present invention (for the structure see Figure 5 to Figure 8 ). On the basis of Embodiment 1 of the present invention, the structure difference of Embodiment 2 lies in:

[0048] The above-mentioned pan bottom 41 and the pot cover 1 are integrally constructed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com