Pressure cooker suitable for preventing splashing and collecting oil

一种高压锅、防喷溅的技术,应用在高压锅领域,能够解决危险、不易推广应用、不利高压锅安全使用等问题,达到增加热能损耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

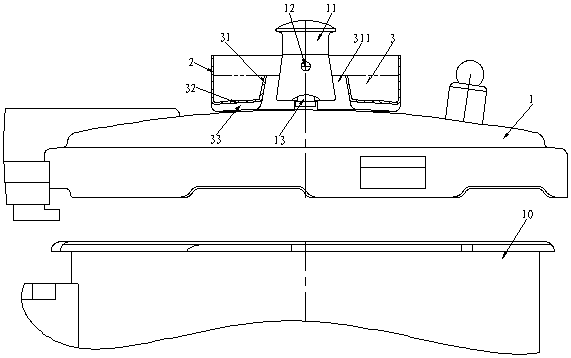

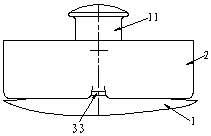

Embodiment 1

[0026] The pressure cooker suitable for anti-splash and collecting oil and water according to Embodiment 1 of the present invention (for the structure see figure 1 , figure 2 and Figure 7. Hereinafter collectively referred to as: the pressure cooker), including a pot body 10 of the pressure cooker and a pot cover 1 with a pressure limiting valve matching it, the pot cover 1 has a circle around the pressure limiting valve to block the spray from the pressure limiting valve. The cylinder cover 2 of the mixed fluid is characterized in that: the lower part of the cylinder cover 2 is provided with a receiving groove 3 on the pot cover 1 around the pressure limiting valve bonnet 11; the receiving groove 3 is composed of the cylinder wall of the cylinder cover 2 and The inner ring wall 31 with the through hole 311 on its inner side and the groove bottom 32 integrally connected between the bottom ends of the two constitute; the minimum aperture of the through hole 311 is greater t...

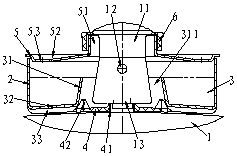

Embodiment 2

[0034] This pressure cooker of embodiment two of the present invention (construction sees image 3 , Figure 4 and Figure 6 to Figure 8 ). On the basis of Embodiment 1 of the present invention, in order to make the function of the pressure cooker of the present invention more perfect, so that it is easier to implement and apply, the following structure is further constructed, namely:

[0035] Further structure 1: the inner circumference of the above-mentioned inner ring wall 31 is provided with a sleeve shoulder 4 which is located on the pot cover 1 and surrounds the pressure limiting valve. The sleeve shoulder 4 is connected to the lower end of the pressure limiting valve sleeve 13 through the sleeve hole 41, and the sleeve There is a suitable distance between the shoulder 4 and the bottom side of the bonnet 11 for the passage of the mixed fluid; the sleeve cover 2 and the receiving groove 3 are loosely fitted on the sleeve shoulder 4 through the inner ring wall 31; the sl...

Embodiment 3

[0045] This pressure cooker of embodiment three of the present invention (structure sees Figure 5 to Figure 8 ), compared with Embodiment 2 of the present invention, its structure is different in that:

[0046] The sleeve shoulder 4 is integrally constructed with the pot cover 1 .

[0047] In the structure of the present embodiment three, the independent member, that is, the sleeve shoulder 4 is omitted, and the structural function of the sleeve shoulder 4 in the embodiment two can be realized by making a local structural change on the pot cover 1, so that the pressure cooker of the present embodiment three The structure is more compact, the use is more convenient and easy to popularize and apply.

[0048] Other configurations and corresponding functions in Embodiment 3 correspond to those described in Embodiment 1 and Embodiment 2, and will not be repeated here.

[0049] Obviously different from the prior art, the ad hoc receiving groove in the pressure cooker of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com