A Production Method for Controlling Straight Crack Defects on the Surface of Medium and Heavy Plates

A production method, the technology of straight edge cracking, which is applied in the production field of controlling the straight edge cracking defects on the surface of medium and thick plates, to achieve the effects of eliminating microscopic segregation defects, reducing tensile stress concentration, and improving high temperature ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

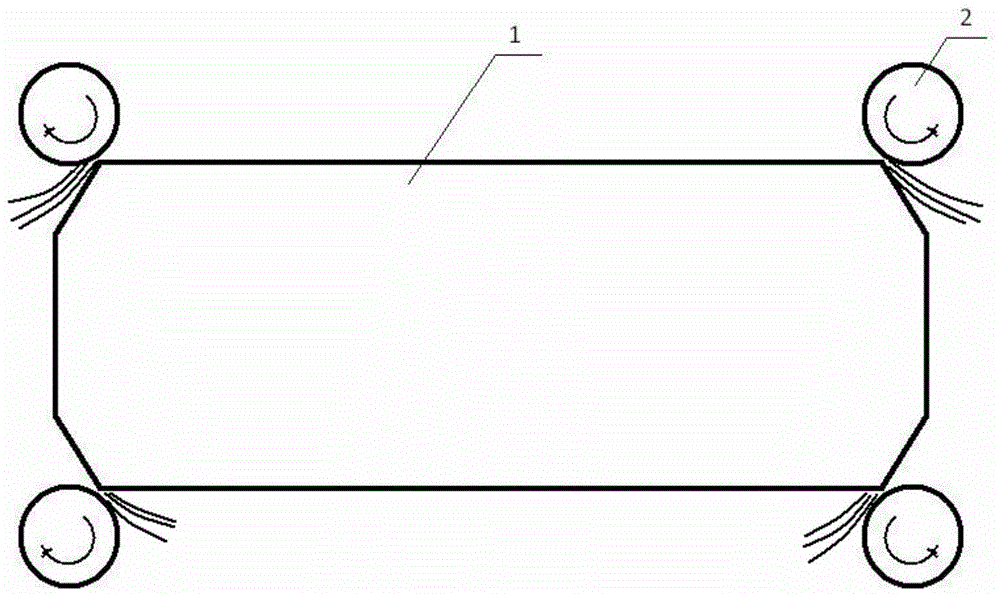

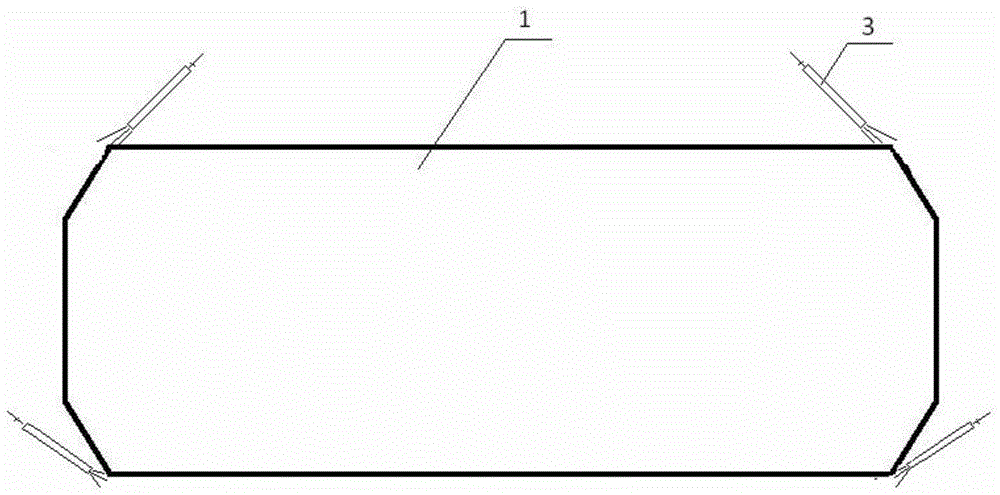

[0039] The specific implementation manner of the present invention will be further described below according to the accompanying drawings.

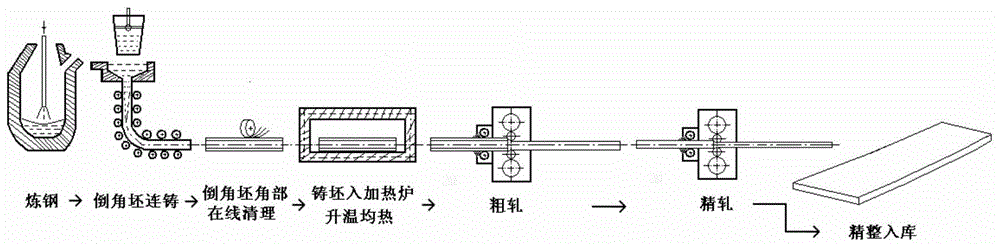

[0040] A production method for controlling straight crack defects on the surface of a medium-thick plate according to the present invention includes the following steps in sequence: steelmaking→continuous casting of chamfered slabs→on-line cleaning of the corners of chamfered slabs→putting the slab into a heating furnace for heating and soaking→rough rolling → Finish rolling → Finishing storage, if attached figure 1 shown. Among them, the chamfering billet continuous casting process must be produced by the chamfering crystallizer (the process of the chamfering mold production chamfering billet can be found in Cao Jianxin, Tao Hongbiao, Zhang Hui, Zhou Mingwei, Zhang Liangzhou, Peng Mingyao, "Chamfering Crystallization Application of the device in continuous casting of slabs in Lianshan Iron and Steel Co., Ltd., Iron and Steel, 2013, 48(1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com