A nickel-based multi-component laser cladding powder and a method for laser cladding the powder

A laser cladding and powder technology, which is applied in the field of laser cladding materials, can solve the problems affecting the overall performance of the repaired workpiece, achieve the effect of repairing defects and damaged parts, ensuring strength and plasticity, and having little thermal influence on the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

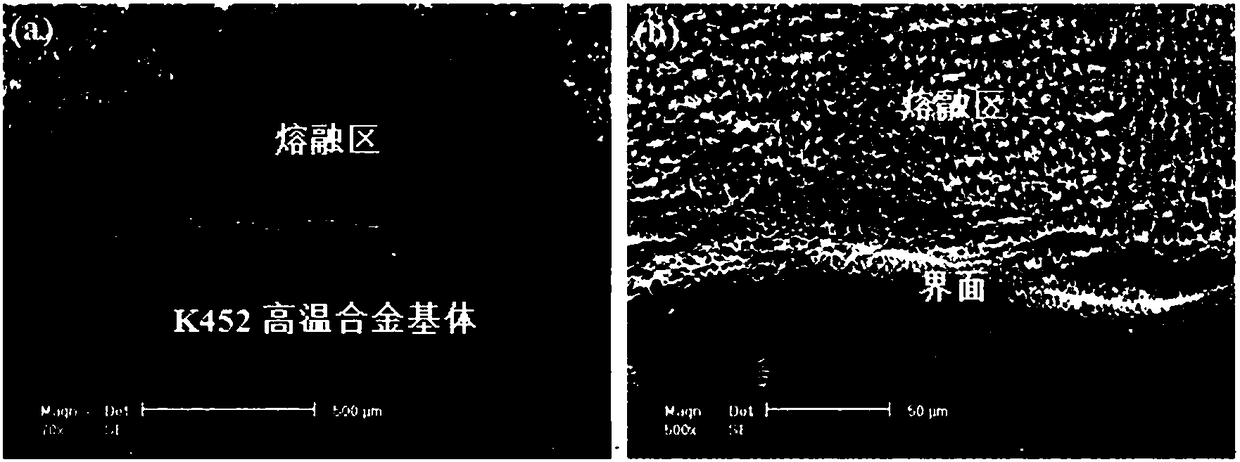

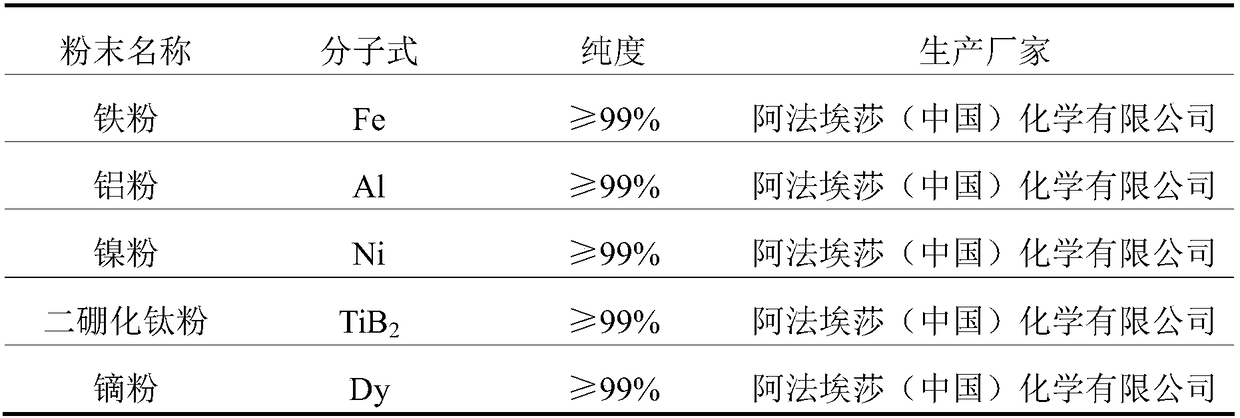

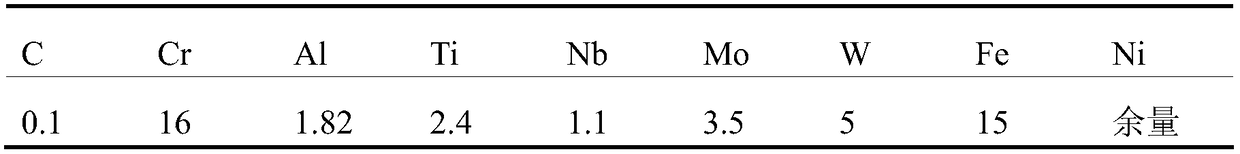

Method used

Image

Examples

Embodiment 1

[0036] Nickel-based multi-component laser cladding powder 91wt%, ethanol 9wt%, the thickness of the prefabricated layer is 1.5mm, the laser power is 1250KW, the spot diameter is 0.8mm, the scanning speed is 240mm / min, the defocus is 0, and the protective gas is Argon, gas flow rate 24L / min.

Embodiment 2

[0038] Nickel-based multi-component laser cladding powder 94wt%, ethanol 6wt%, the thickness of the prefabricated layer is 1.0mm, the laser power is 1000KW, the spot diameter is 0.6mm, the scanning speed is 280mm / min, the defocus is 0, and the protective gas is Argon, gas flow rate 20L / min.

Embodiment 3

[0040] Nickel-based multi-component laser cladding powder 90wt%, ethanol 10wt%, the thickness of the prefabricated layer is 1.2mm, the laser power is 900KW, the spot diameter is 0.8mm, the scanning speed is 300mm / min, the defocus is 0, and the protective gas is Argon, gas flow rate 20L / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com