Vehicle-used secondary battery

A technology for secondary batteries and vehicles, applied in secondary batteries, secondary battery manufacturing, batteries, etc., can solve the problems of difficult to avoid deformation of cell shells, buckling deformation of cell shells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, the embodiments described below are not limited to the exemplified examples, and there is no intention to exclude the application of various modifications or techniques not explicitly described in the embodiments described below. Various configurations of the following embodiments can be implemented with various modifications within the range that does not violate the gist of the present invention, and various trade-offs or appropriate combinations can also be selected as required.

[0055] Also, although it was exemplified that the vehicular secondary battery according to the various embodiments is applicable to automobiles, the present vehicular secondary battery is also effectively applicable to vehicles other than automobiles.

[0056] [1. The first embodiment]

[0057] [1-1. Overall composition]

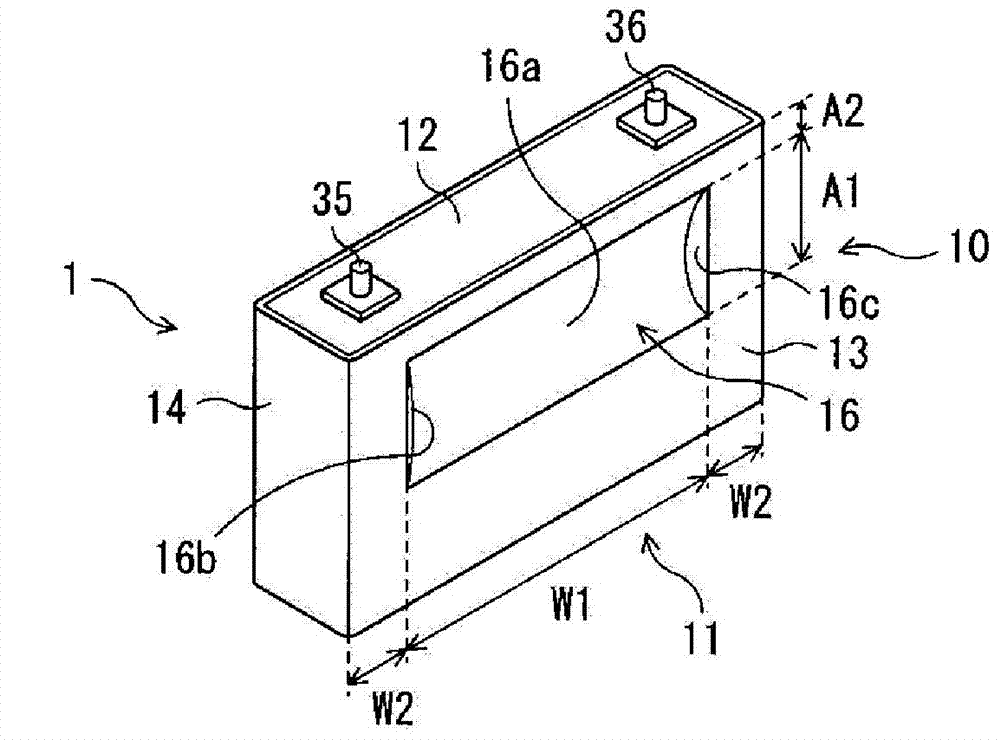

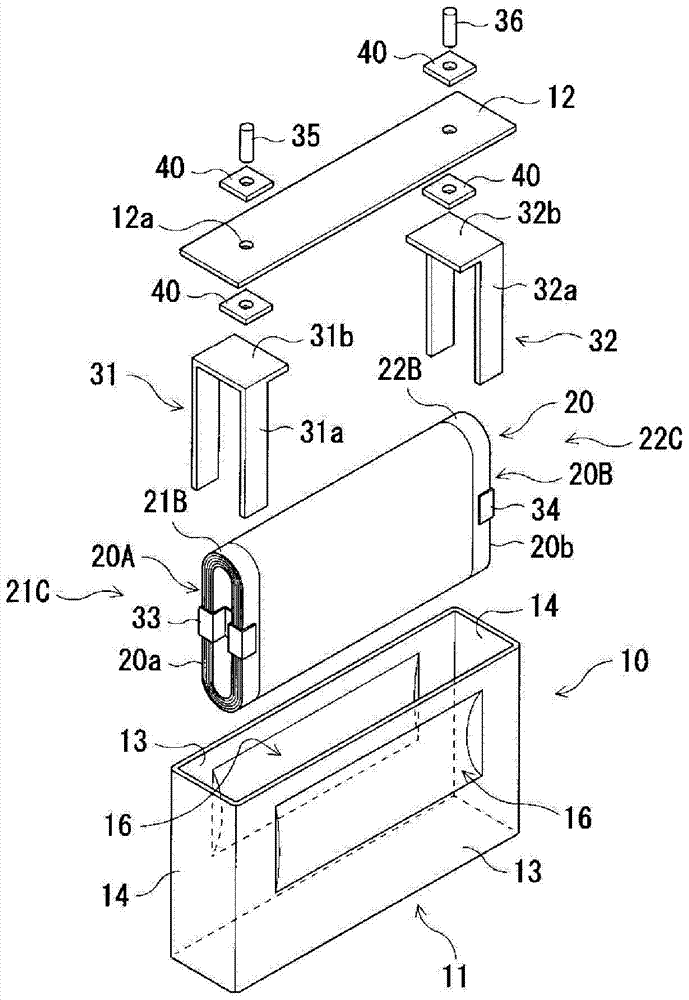

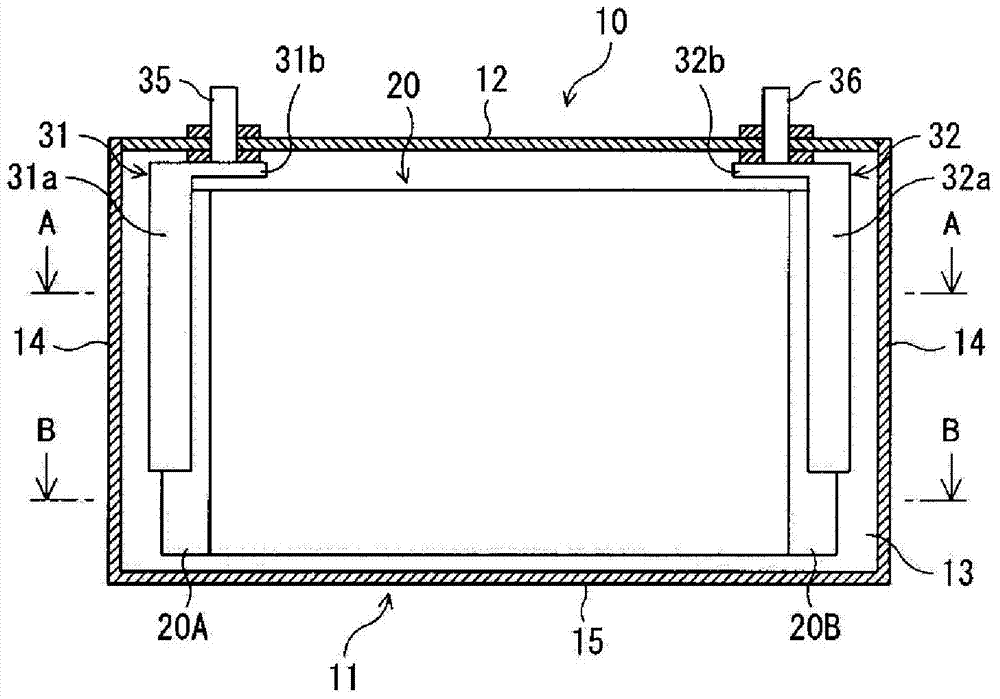

[0058] use figure 1 The vehicle secondary battery acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com