Digital printing structure suitable for small rotary printing machine and digital rotary printing machine

A technology of digital printing and printing presses, applied in rotary printing presses, printing presses, printing and other directions, can solve the problems of large volume, affecting the success of the transformation, insufficient installation of digital printing equipment, etc., and achieve the effect of good integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

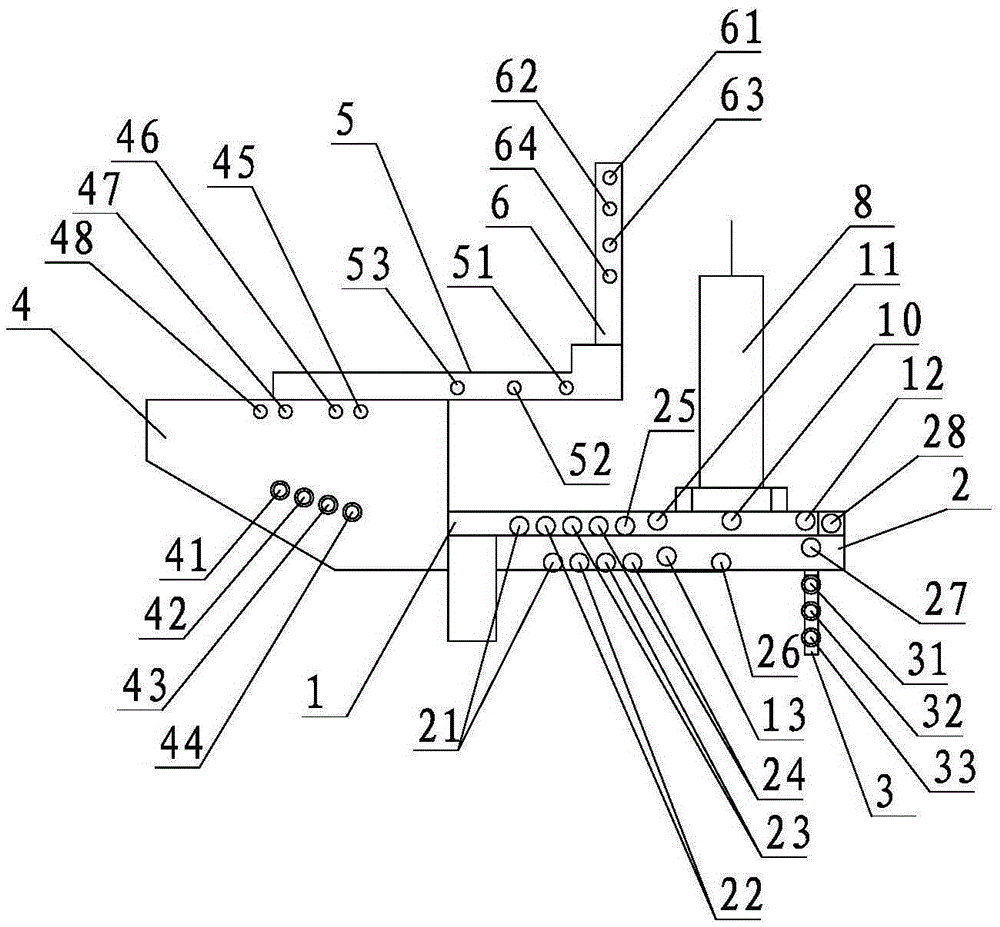

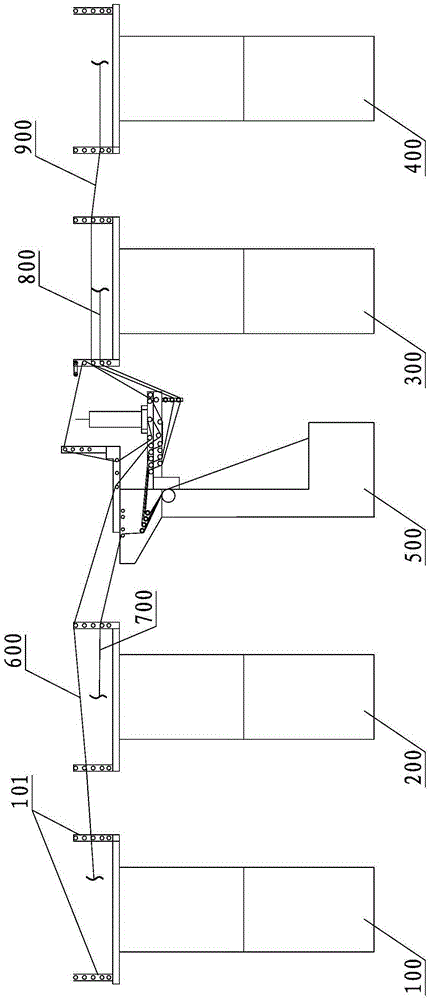

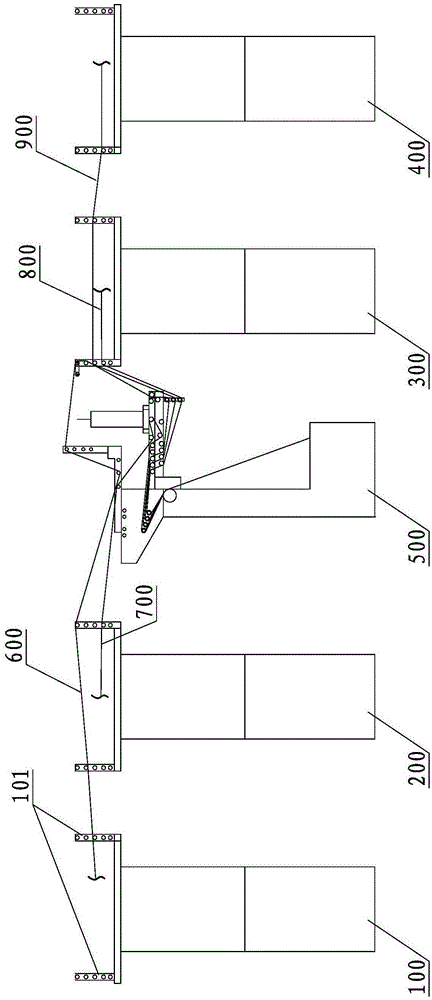

[0036] see figure 1 , The present invention relates to a digital printing structure suitable for a small rotary printing machine, which includes a paper guiding mechanism of a folding machine, a digital printing head and a paper guiding reversing mechanism. Wherein, the paper guiding mechanism of the folder is composed of the base frame 4 and the extension frame 5 on the base frame 4 . The paper guide reversing mechanism includes a main frame 1 , an auxiliary frame 2 , a vertical frame 3 and a paper guide roller frame 6 .

[0037] In the reversing mechanism, the upper end of the main frame 1 is straddled with a guide rail, and the digital printing head 8 is slidably arranged on the guide rail, and the sub-frame 2 is arranged at the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com