A kind of tank calciner volatile matter channel

A pot calciner and volatile matter technology, applied in furnaces, crucible furnaces, furnace components, etc., can solve the problems of wasting energy, reducing furnace service life, reducing output, etc., saving investment, prolonging service life, and increasing production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited by the examples.

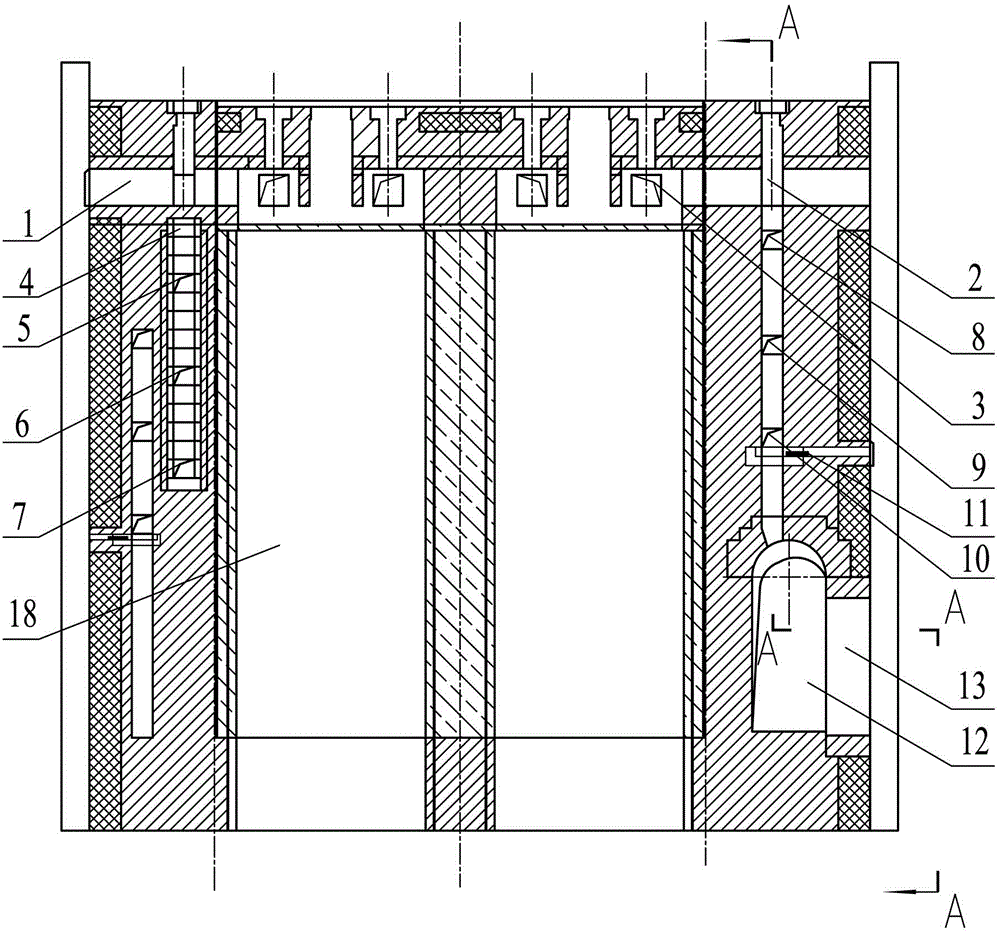

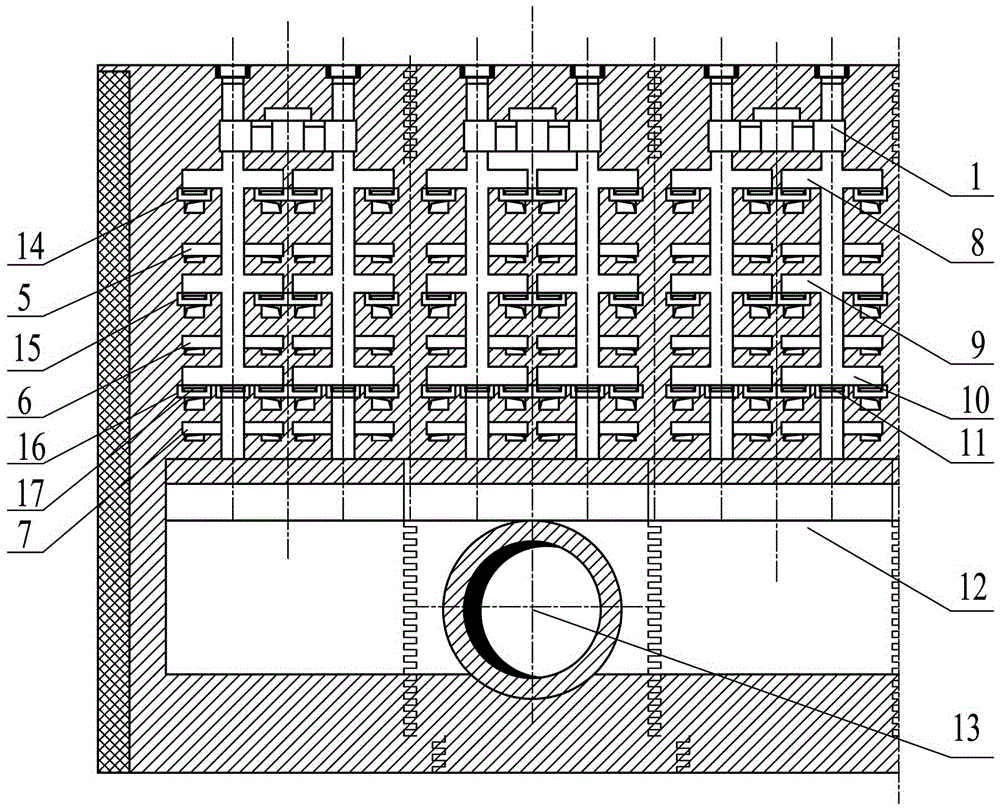

[0018] As shown in the figure, a kind of tank-type calciner volatile matter channel of the present invention comprises a material tank 18, a volatile matter concentration channel 1 on the upper part of the material tank, a front wall and a rear wall, and a front wall volatile matter vertical channel 2 is provided in the front wall, The lower part of the front wall is provided with flue gas concentrating channel 12, and the vertical volatile matter channel 2 of the front wall starts from the volatile matter concentrating channel 1 on the upper part of the material tank and directly leads to the flue gas concentrating channel 12 of the flue gas, and the volatile matter of the first floor flue gas is divided horizontally. Road 8, three-layer fire channel volatile content horizontal sub-channel 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com