Power line connecting structure of stator

A technology for power lines and stators, which is applied in the field of construction of connecting power lines, can solve problems such as difficulty in ensuring creepage, spatial distance, and complex connection structures, and achieves the effects of high degree of freedom, improved reliability, and creepage assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0039] The power line connection structures of Embodiments 1 and 2 are structures in which lead wires serving as power lines are connected to a wiring board included in a stator.

[0040] In the power line connection structure of Embodiment 1, the core wire of the lead wire is arranged in the lead-in terminal that can be reduced in diameter coupled with the pad of the wiring board, and the cover part and the core wire of the lead wire are crimped after the lead-in terminal is crimped. In the state, connect the core wire of the lead wire to the lead-in terminal.

[0041] In the power line connection structure of Embodiment 2, the insertion terminal coupled with the lead wire is arranged in the lead-in terminal coupled to the pad of the wiring board, and the lead-in terminal is crimped in a state where the lead-in terminal is crimped. Next, combine the insertion terminal of the lead wire with the lead-in terminal.

[0042] According to the structure of Embodiment 1 and Embodime...

Embodiment approach 1

[0044]

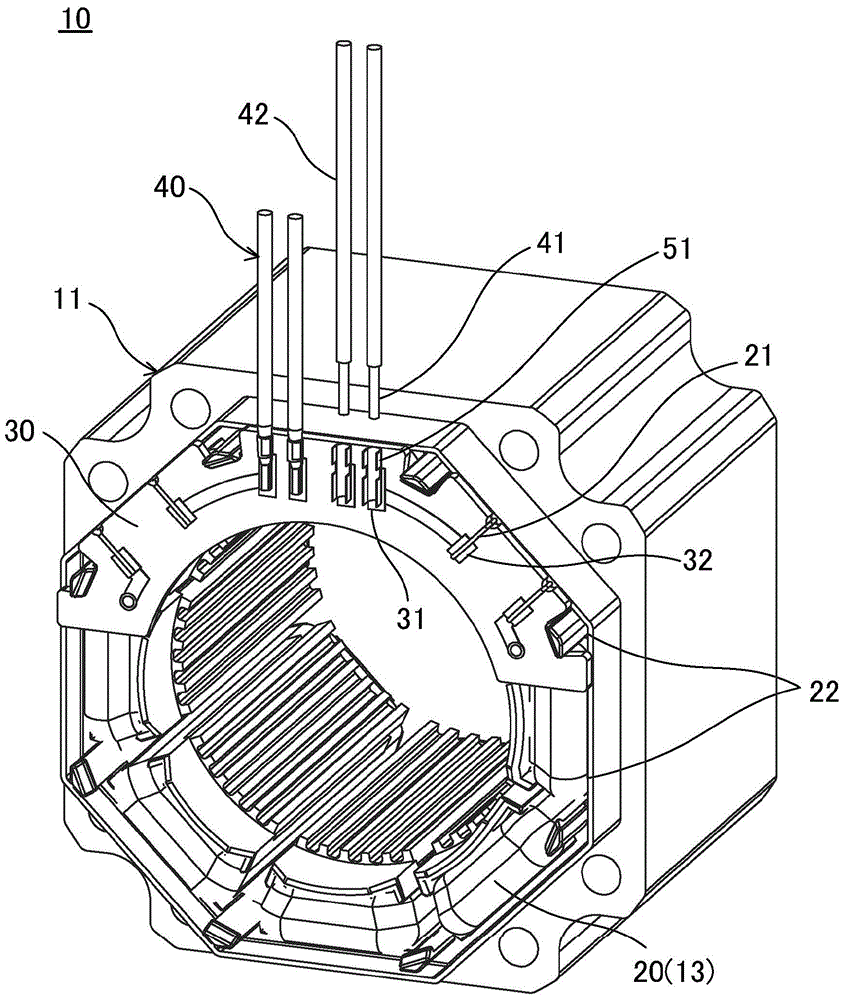

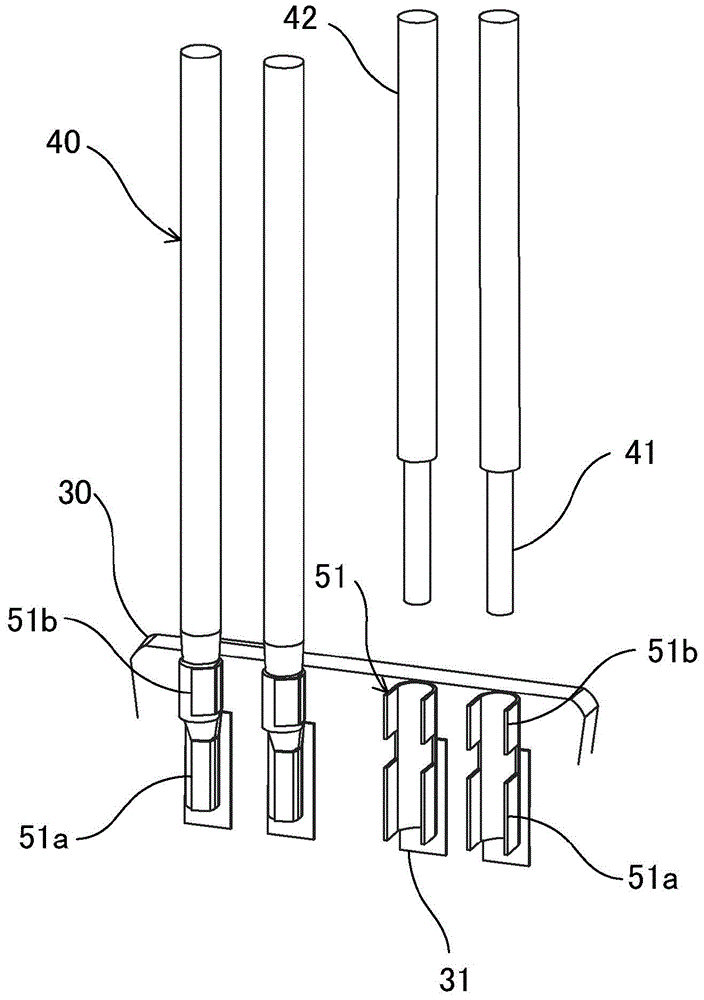

[0045] First, refer to figure 1 and figure 2 The power line connection structure of the stator according to Embodiment 1 will be described. figure 1 It is a perspective view of the power line connection structure of the stator of Embodiment 1. figure 2 yes figure 1 An enlarged view of the main part.

[0046] Such as figure 1 As shown, for example, a stator core 11 of a stator 10 of a stepping motor has a plurality of pole teeth 13 . Insulated electric wires 21 such as enameled wires, for example, are wound around the pole teeth 13 to form a plurality of coils 20 . The poles of the coil 20 are connected by jumper wires 22 to form the respective phases of the motor. The winding start or end of the insulating film electric wire 21 of each phase coil 20 is connected to the power line 40 from the power source on the wiring board 30 .

[0047] As the wiring board 30 of this embodiment, for example, a printed wiring board with a wiring pattern formed by a photolit...

Embodiment approach 2

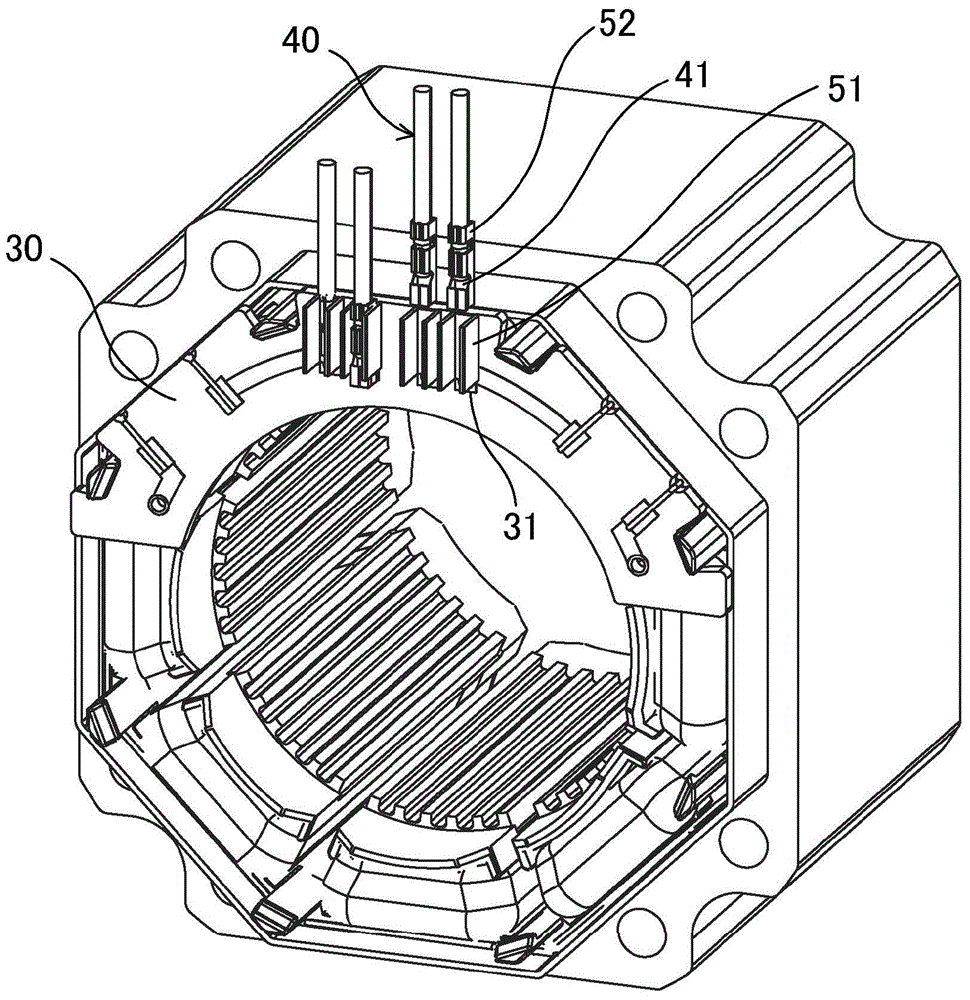

[0068] Next, refer to image 3 and Figure 4 The power line connection structure of the stator according to Embodiment 2 will be described. image 3 It is a perspective view of the power line connection structure of the stator of Embodiment 2. Figure 4 yes image 3 An enlarged view of the main part.

[0069] Such as image 3 As shown, the power line connection structure of the stator according to Embodiment 2 is different from Embodiment 1 in that the covering part of the lead wire 40 is crimped on the lead-in terminal 51 and the insertion terminal 52 is crimped on the core wire 41 to perform crimping. combined.

[0070] That is, in the power line connection structure of the stator according to Embodiment 2, the lead-in terminals 51 that can be reduced in diameter by a pressing device such as a crimping machine are bonded to the power line connection pads 31 of the wiring board 30 . On the other hand, an insertion terminal 52 is coupled to the covering portion of the le...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap