A steel belt granulator

A granulator and steel belt technology, which is applied in the field of machinery and equipment for making granules, can solve the problems of uneven edge deformation of granulated steel belts, shortened equipment service life, affecting normal production, etc. The effect of equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

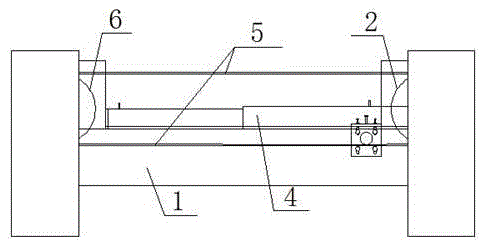

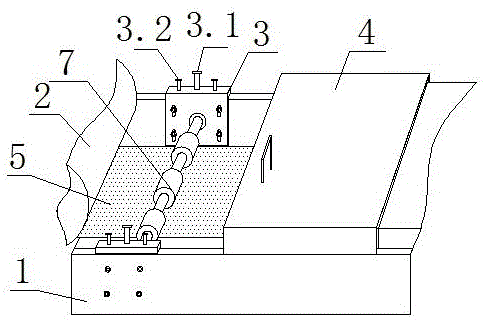

[0014] Below in conjunction with specific embodiment the present invention is further described: a kind of steel belt granulator, comprises frame 1, and frame 1 two ends are respectively provided with driving roller 6 and driven roller 2, and driving roller 6 and driven roller 2 are equipped with The granulation steel belt 5 driven by the driving roller 6 is wrapped around, and the lower end of the frame 1 is provided with a pressure roller type steel belt tension regulator; the steel belt tension regulator includes a pressure roller 7 and two lifting frames 3, two Two lifting frames 3 are respectively installed on the inside of both sides of the frame 1, and the two ends of the pressure roller 7 are respectively assembled on the two lifting frames 3 through bearings, and the pressure roller 7 is pressed against the rotating part of the granulation steel belt 5 near the end of the driven roller 2 The back of the lifting frame 3 is an "L"-shaped metal plate, the long plate part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com